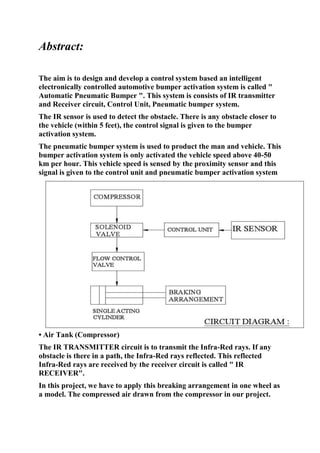

This document summarizes an engineering project on an automatic pneumatic bumper system for vehicles. The system uses IR sensors to detect obstacles within 5 feet of the vehicle traveling over 40-50 km/hr. When an obstacle is detected, the control unit activates the pneumatic bumper and braking system to protect both the vehicle and people. The pneumatic bumper is designed to absorb impact through compressed air and materials like foam and plastic to reduce injury. The system aims to increase safety and provide fast automatic braking responses in pre-crash situations on roads.