Embed presentation

Downloaded 22 times

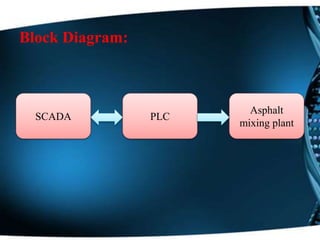

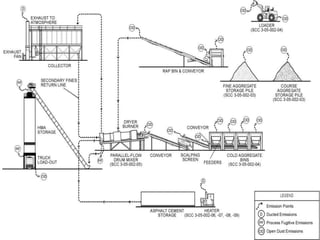

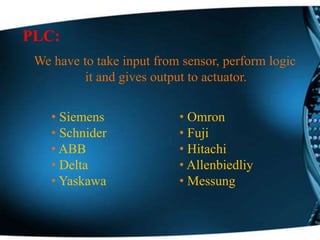

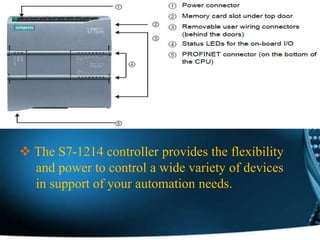

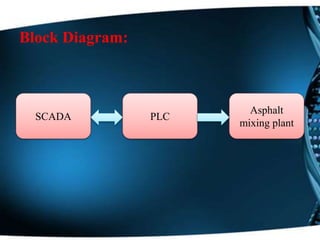

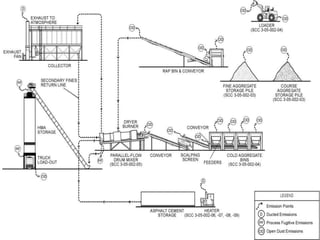

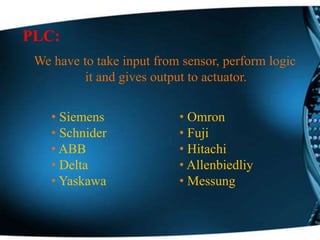

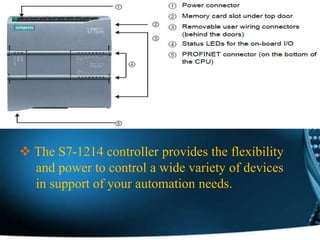

This document discusses using a programmable logic controller (PLC) and supervisory control and data acquisition (SCADA) system to control an asphalt batch mixing plant. A PLC takes input from sensors, performs logic functions, and outputs to actuators to control devices. A SCADA system provides supervisor-level control, displays graphs and faults, stores data, and has graphical interfaces. The system has advantages like improved safety, environmental friendliness, low maintenance costs, and fuel efficiency. Its disadvantages include needing skilled labor and higher costs.