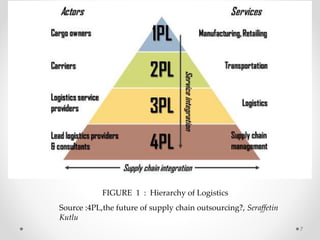

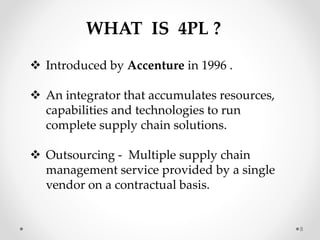

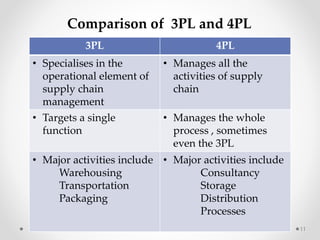

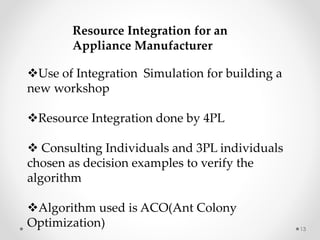

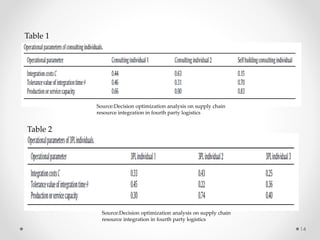

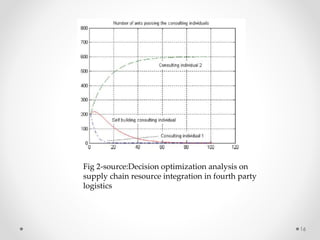

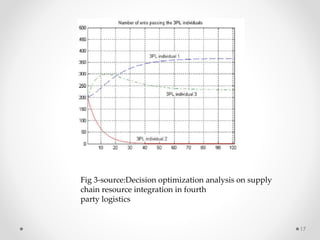

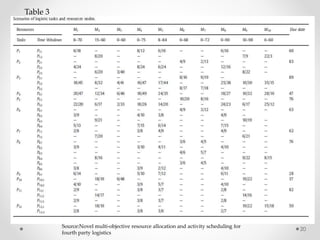

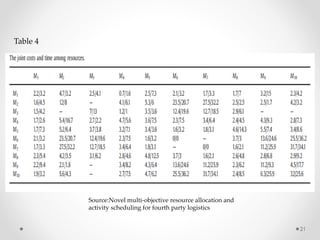

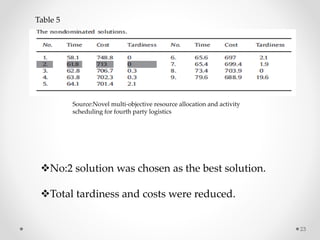

This document provides an overview of 4PL logistics. It defines 4PL as an integrator that accumulates resources, capabilities and technologies to run complete supply chain solutions. The document outlines the key differences between 3PL and 4PL providers. It then describes two case studies where 4PL was used: one involving resource integration for an appliance manufacturer using ant colony optimization, and another involving logistics market scheduling in Wuhan using a genetic algorithm. Both cases showed 4PL approaches improved coordination, flexibility, and reduced costs and tardiness compared to traditional 3PL approaches.