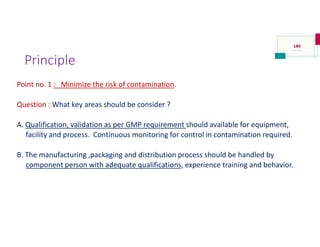

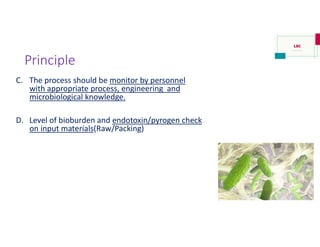

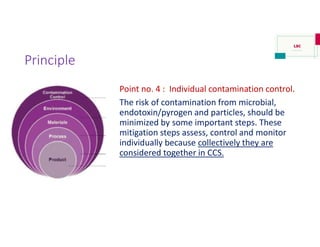

This document provides guidance for ensuring sterility in the manufacture of sterile medicinal products through a contamination control strategy (CCS). The CCS should establish robust assurance of contamination prevention from microbial, endotoxin/pyrogen and particulate sources. It involves identifying risks to product quality using quality risk management and putting in place controls like facility design, equipment qualification, environmental monitoring, personnel training and change control to minimize these risks. The CCS must describe all elements of the manufacturing process and be reviewed periodically for effectiveness in assuring sterility of the final product.