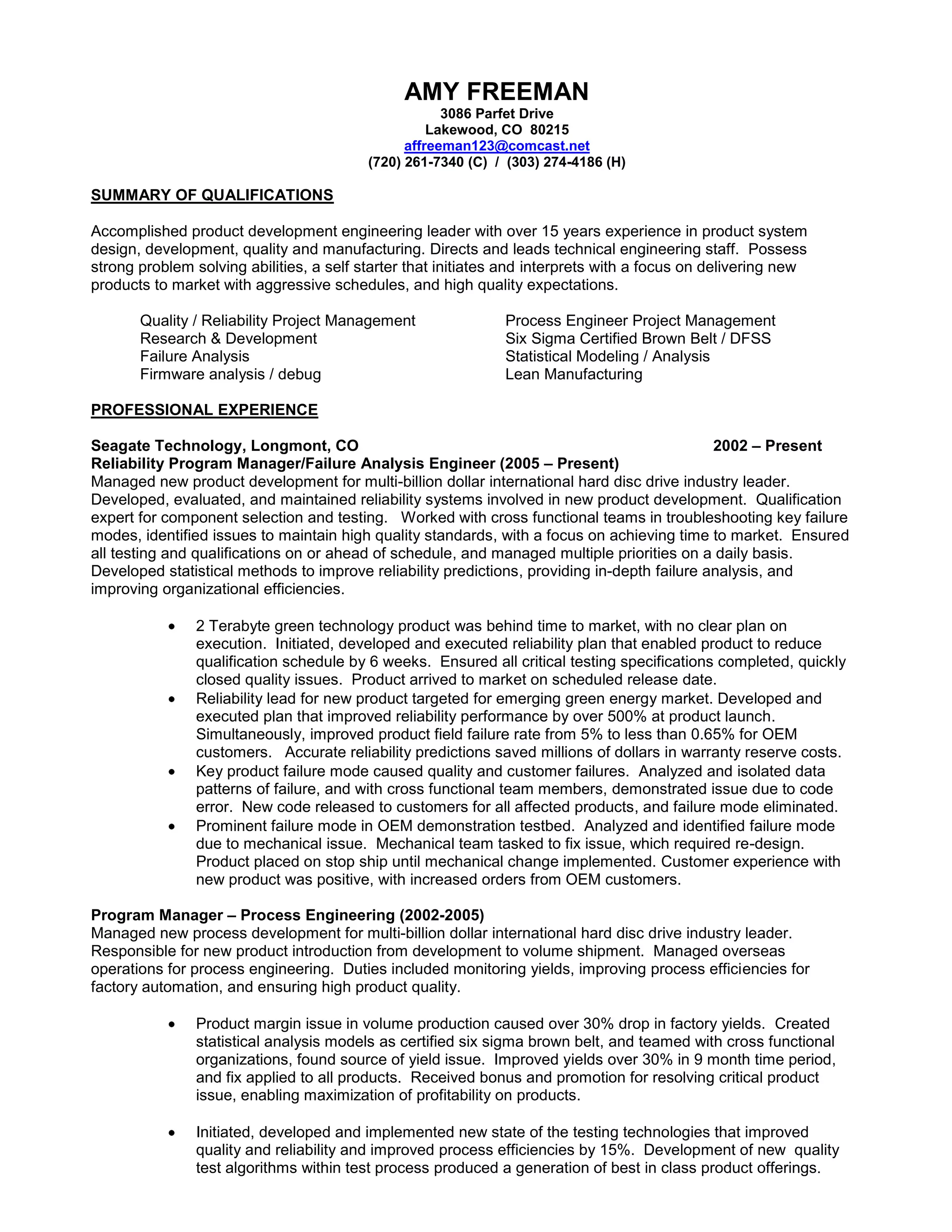

Amy Freeman is a product development engineering leader with over 15 years of experience in product design, development, quality, and manufacturing. She currently works as a Reliability Program Manager and Failure Analysis Engineer at Seagate Technology, where she has led various projects that improved product reliability and quality. Prior to this, she held engineering roles at Celestica, Lucent-Bell Laboratories, and CoorsTEK. She has a B.S. in Mechanical Engineering and is Six Sigma certified.