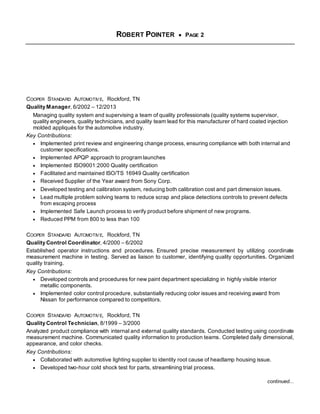

Robert Pointer has over 20 years of experience in quality engineering, process improvement, and product development for the automotive industry. He has a proven track record of managing all phases of new product development from concept to production and implementing process improvements that reduced costs and improved quality. His experience includes quality engineering roles at Cooper Standard Automotive where he led quality programs, achieved certification to ISO/TS16949, and reduced defects and customer complaints. He holds a degree in chemical engineering and certifications in Lean Manufacturing, Kaizen, and as a Certified Manager of Quality.