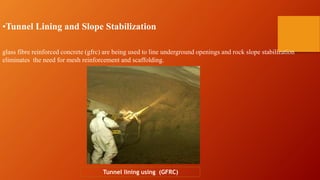

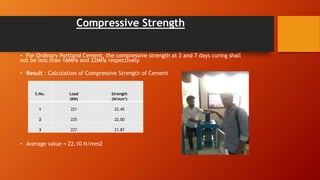

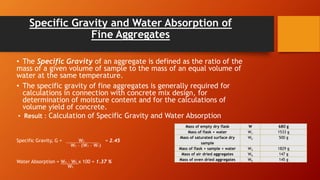

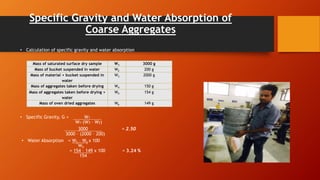

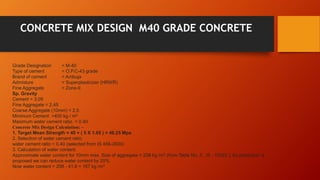

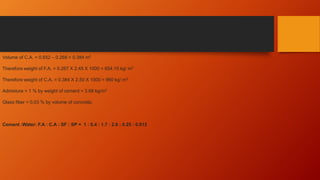

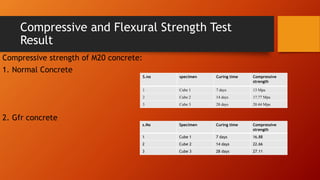

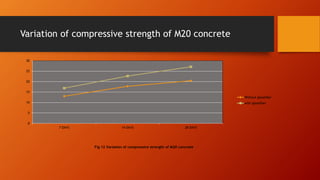

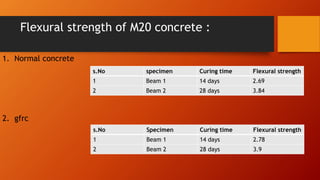

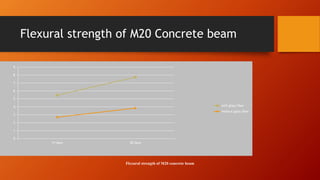

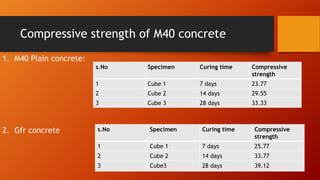

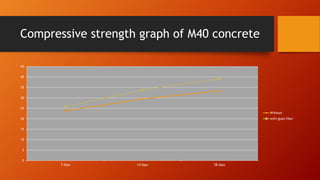

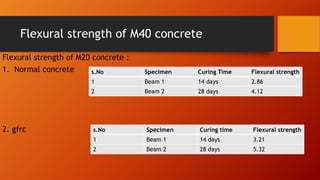

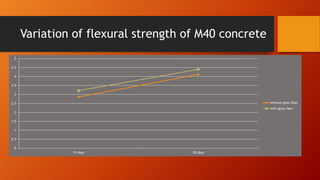

This document discusses glass fiber reinforced concrete (GFRC). It begins by defining fiber reinforced concrete and discussing the effects of fibers in concrete, including improved crack resistance and reduced permeability. Several types of glass fibers are described, and the properties of glass fibers and GFRC are outlined. These include high tensile strength, impact resistance, fire endurance, and resistance to cracks in concrete. The document also covers mixing, casting, and applications of GFRC, as well as tests conducted to evaluate the compressive and flexural strength of GFRC. Results showed that GFRC exhibited higher strength properties than normal concrete.