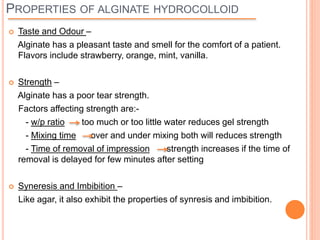

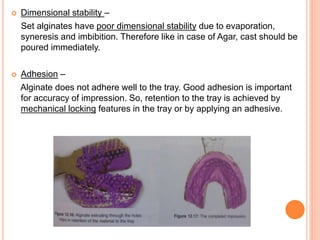

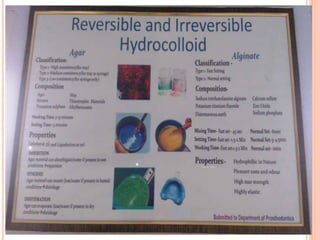

Alginate is a commonly used impression material that is extracted from brown seaweed. It sets via a chemical reaction when its powder form is mixed with water. The powder contains soluble sodium alginate which reacts with calcium sulfate in the powder to form insoluble calcium alginate. Sodium phosphate is also included as a retarder to increase working time before the reaction occurs. Alginate has advantages of being easy to use, inexpensive, and comfortable for patients. However, it has disadvantages like poor dimensional stability, strength, and accuracy for complex impressions.