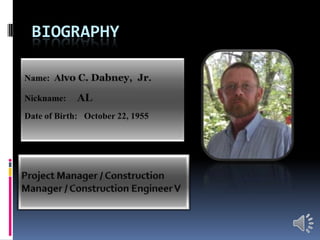

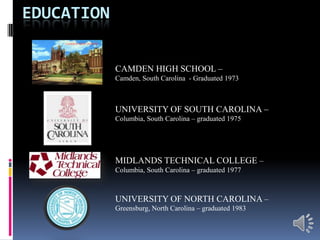

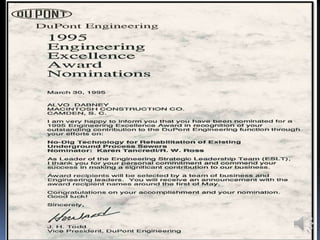

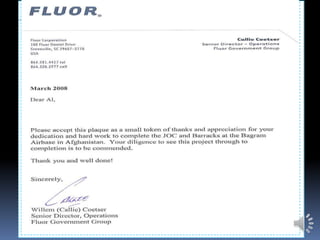

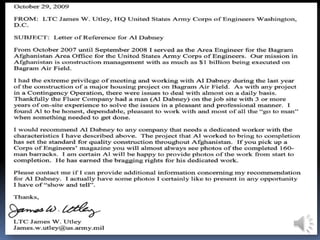

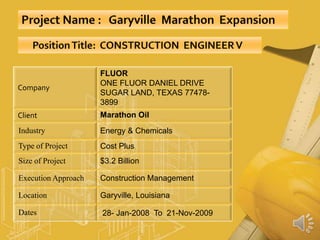

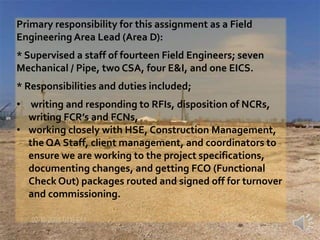

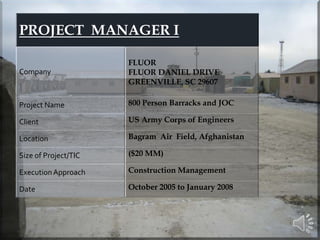

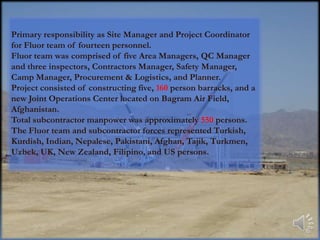

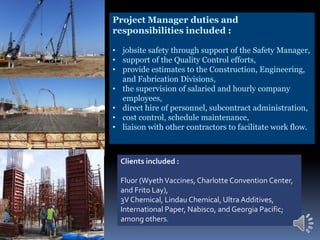

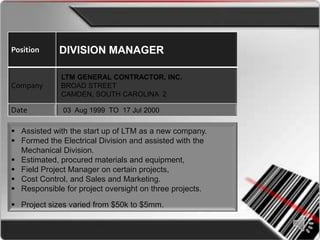

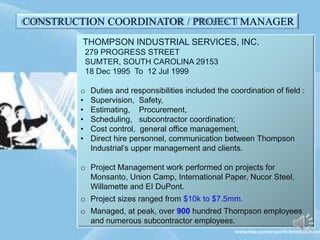

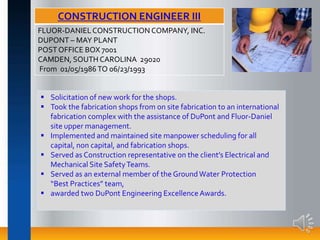

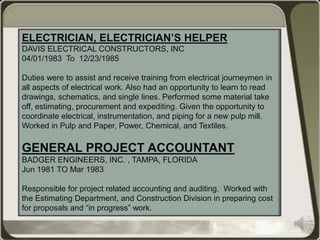

This document contains a biography and resume for Alvo C. Dabney Jr. It summarizes his education, which includes graduating from Camden High School in 1973 and obtaining degrees from the University of South Carolina in 1975 and Midlands Technical College in 1977. It also outlines his extensive experience over 40 years in project management and construction roles for companies like Fluor, Southeland Associates, and Thompson Industrial Services on industrial and military projects domestically and internationally.