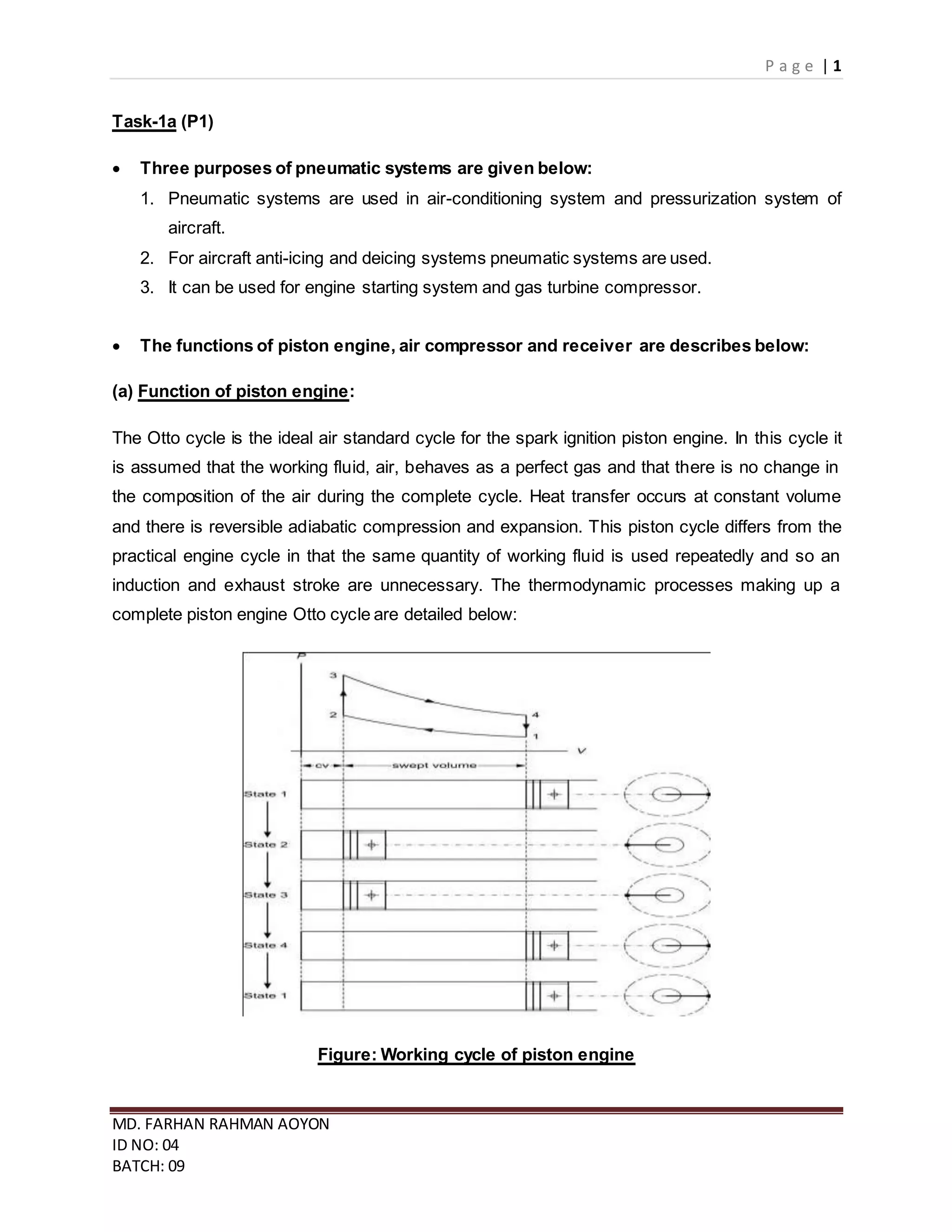

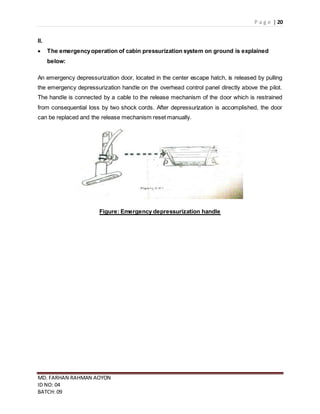

The document discusses pneumatic supply systems for piston engines and gas turbine engines. For piston engines, low-pressure air is compressed by a vane-type pump and stored in an accumulator to provide a continuous supply for pneumatic systems like wing deicing boots. For gas turbine engines, bleed air is extracted from one or more compressor stages to supply pneumatic systems, commonly from a low pressure port at an intermediate stage and a high pressure port at a later stage.