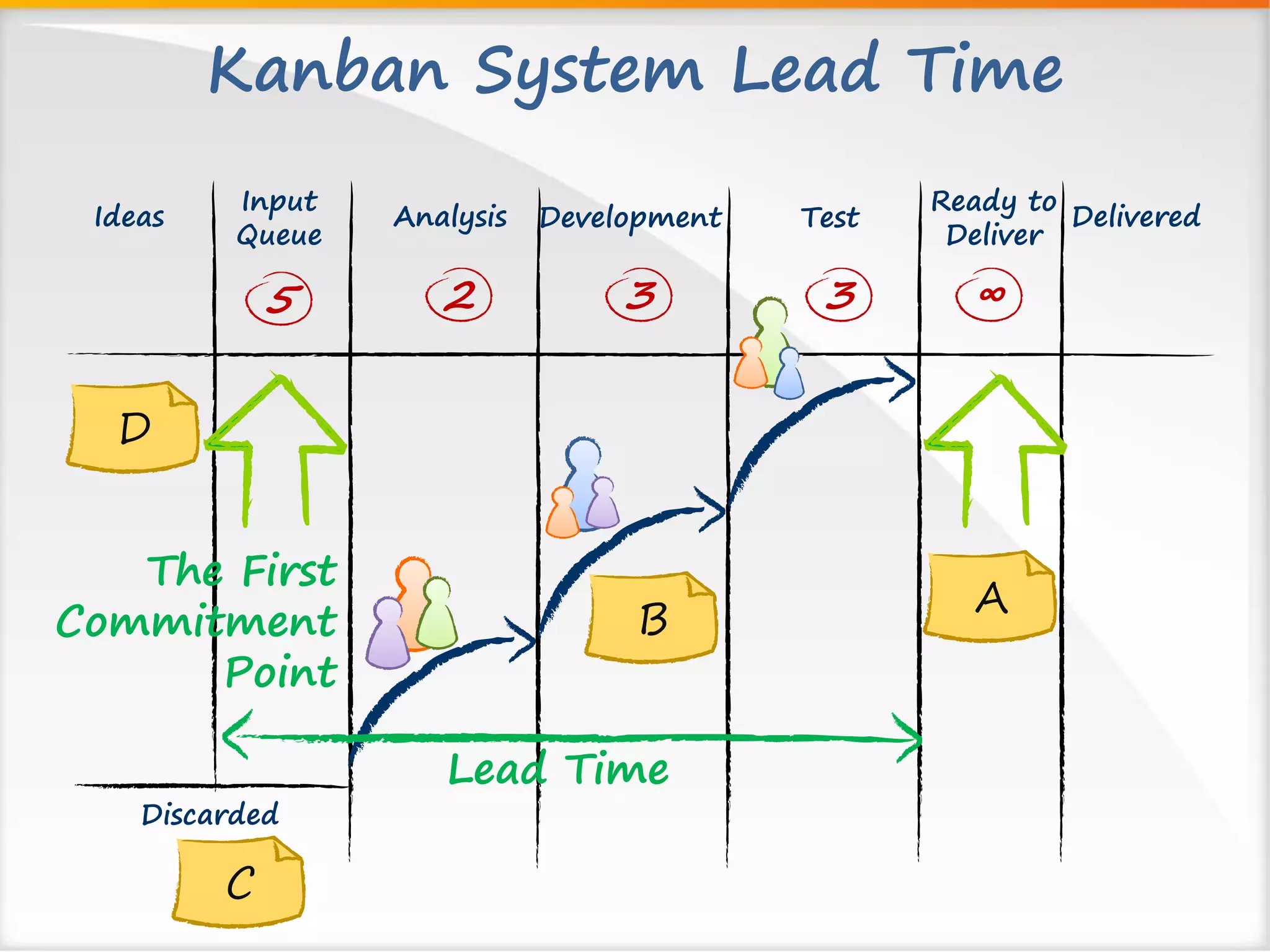

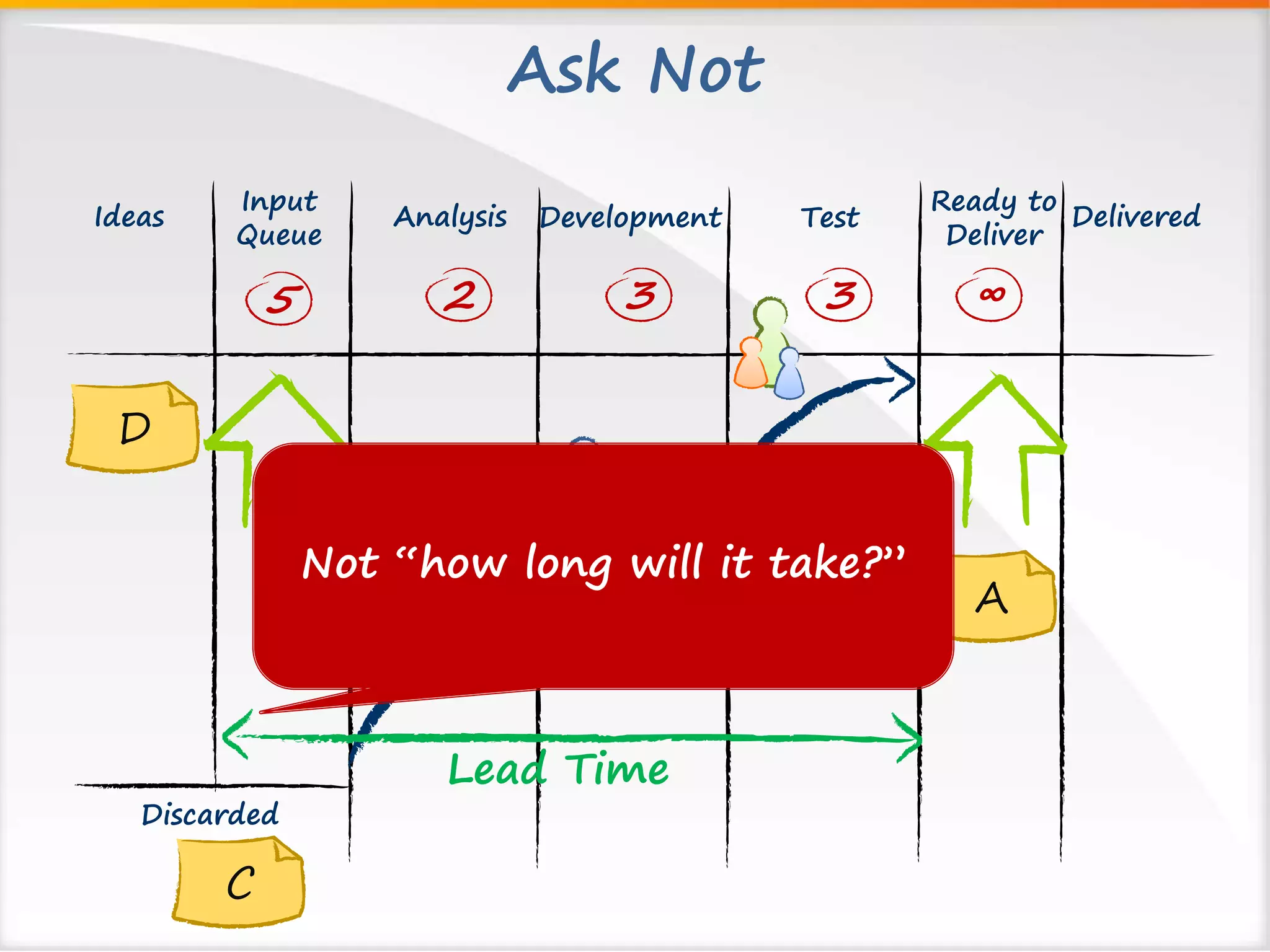

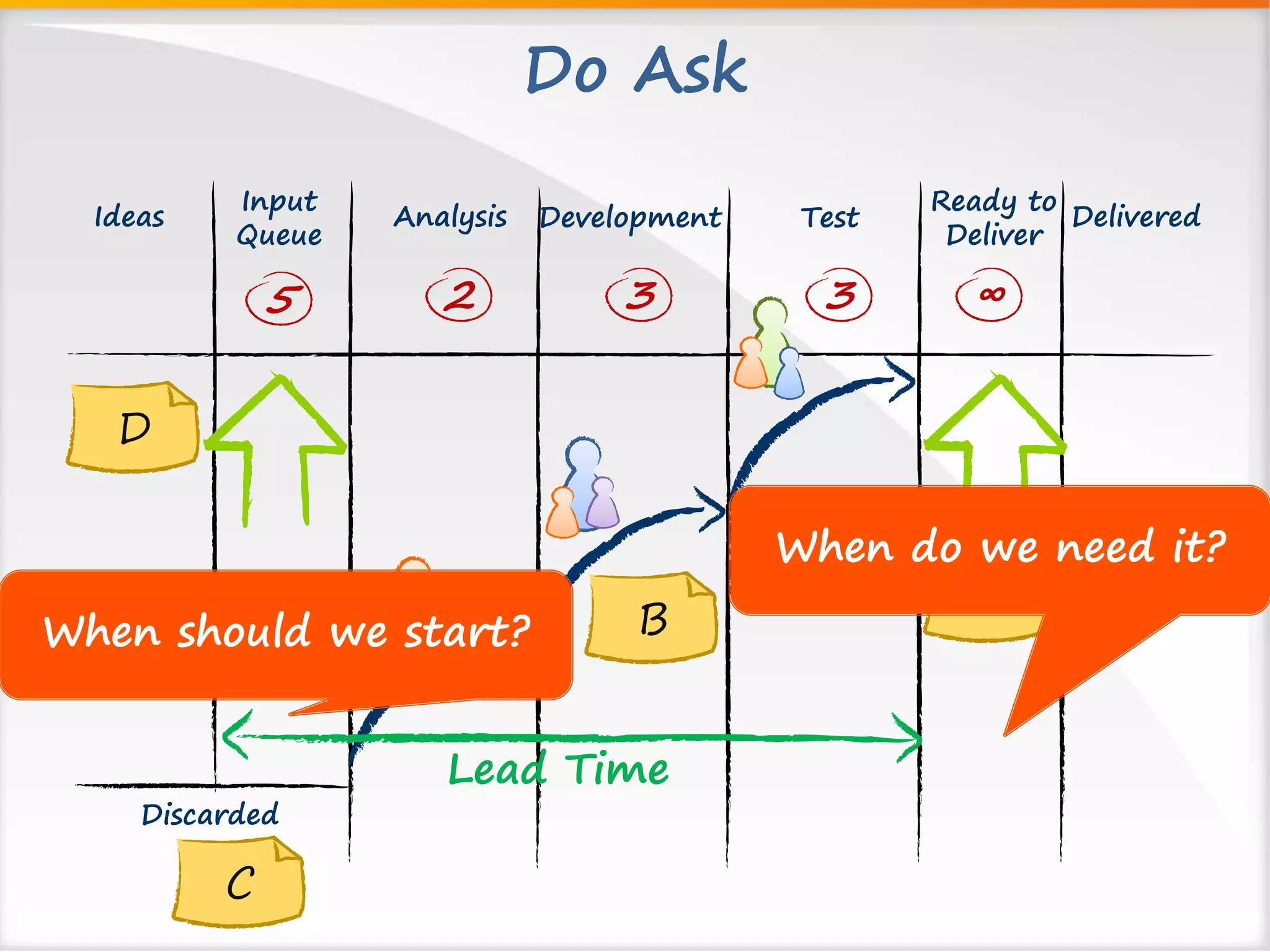

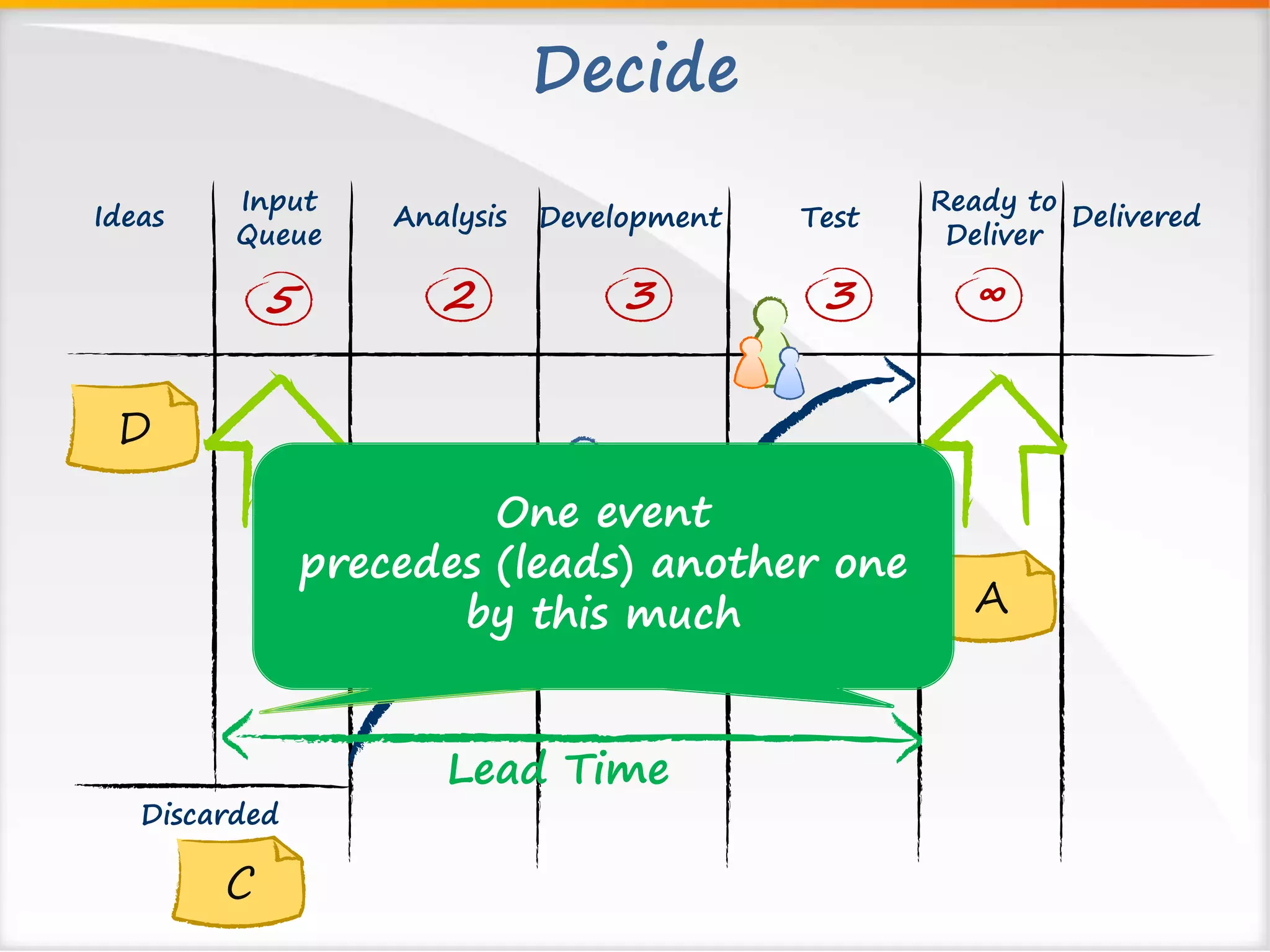

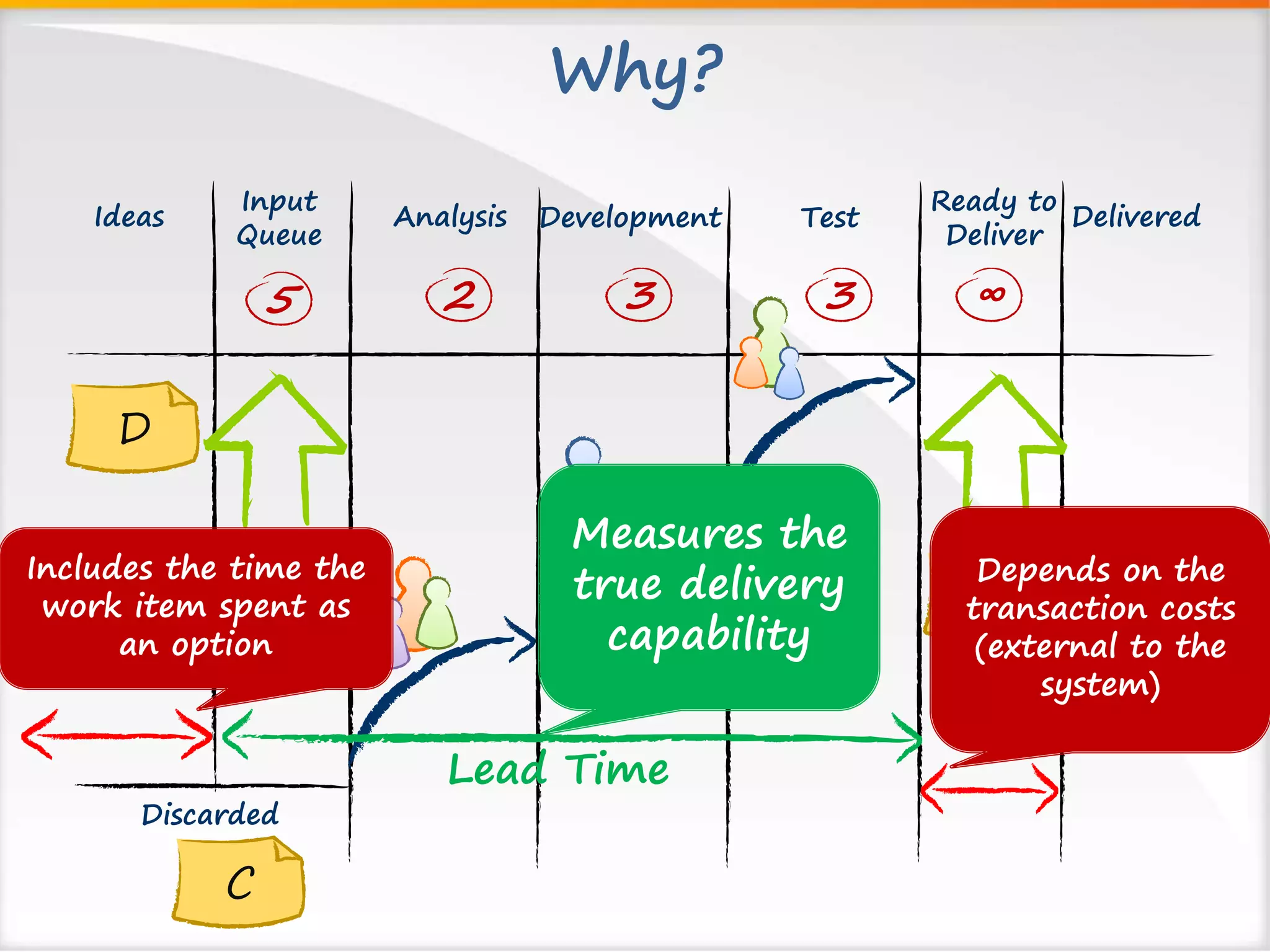

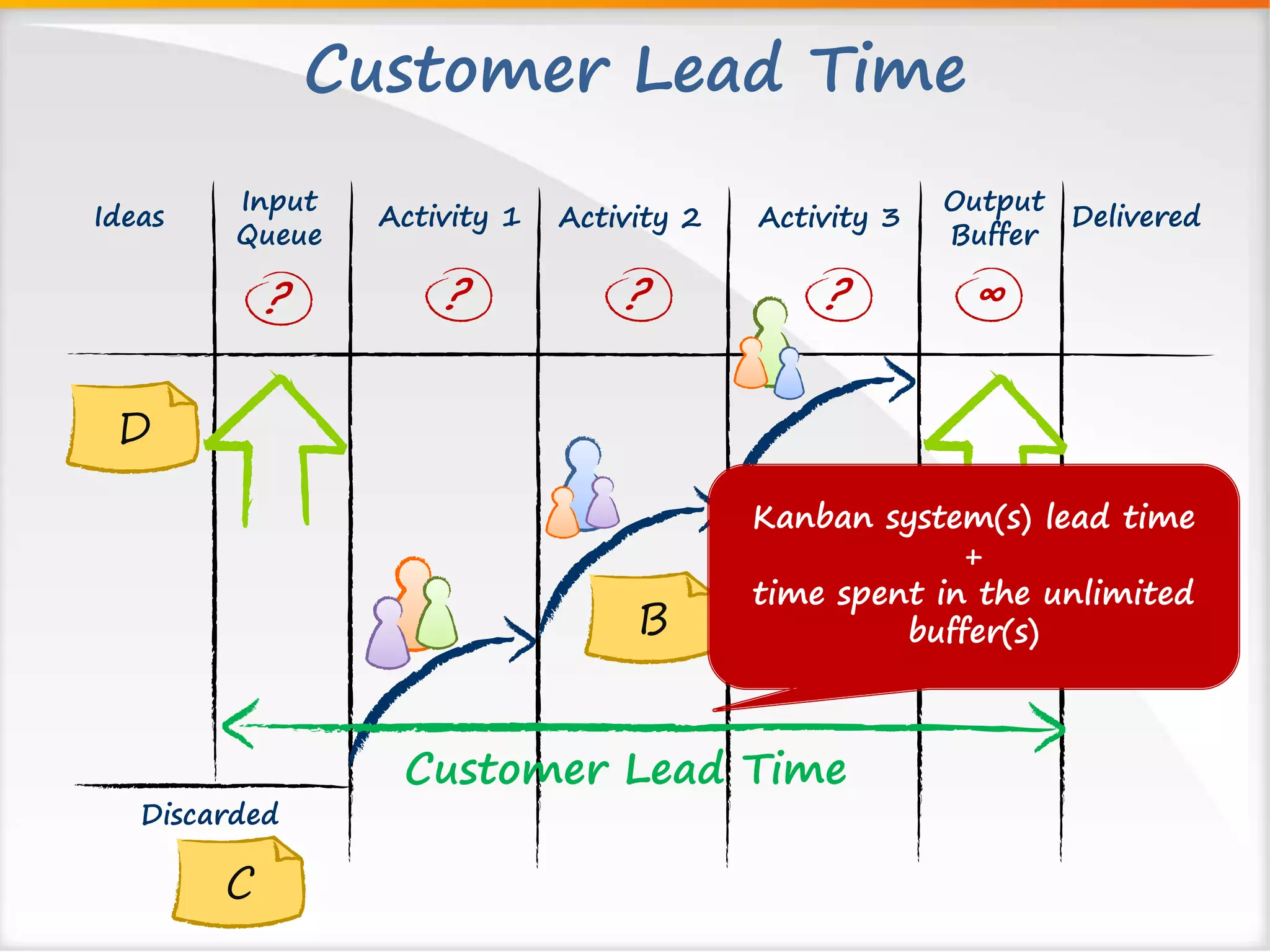

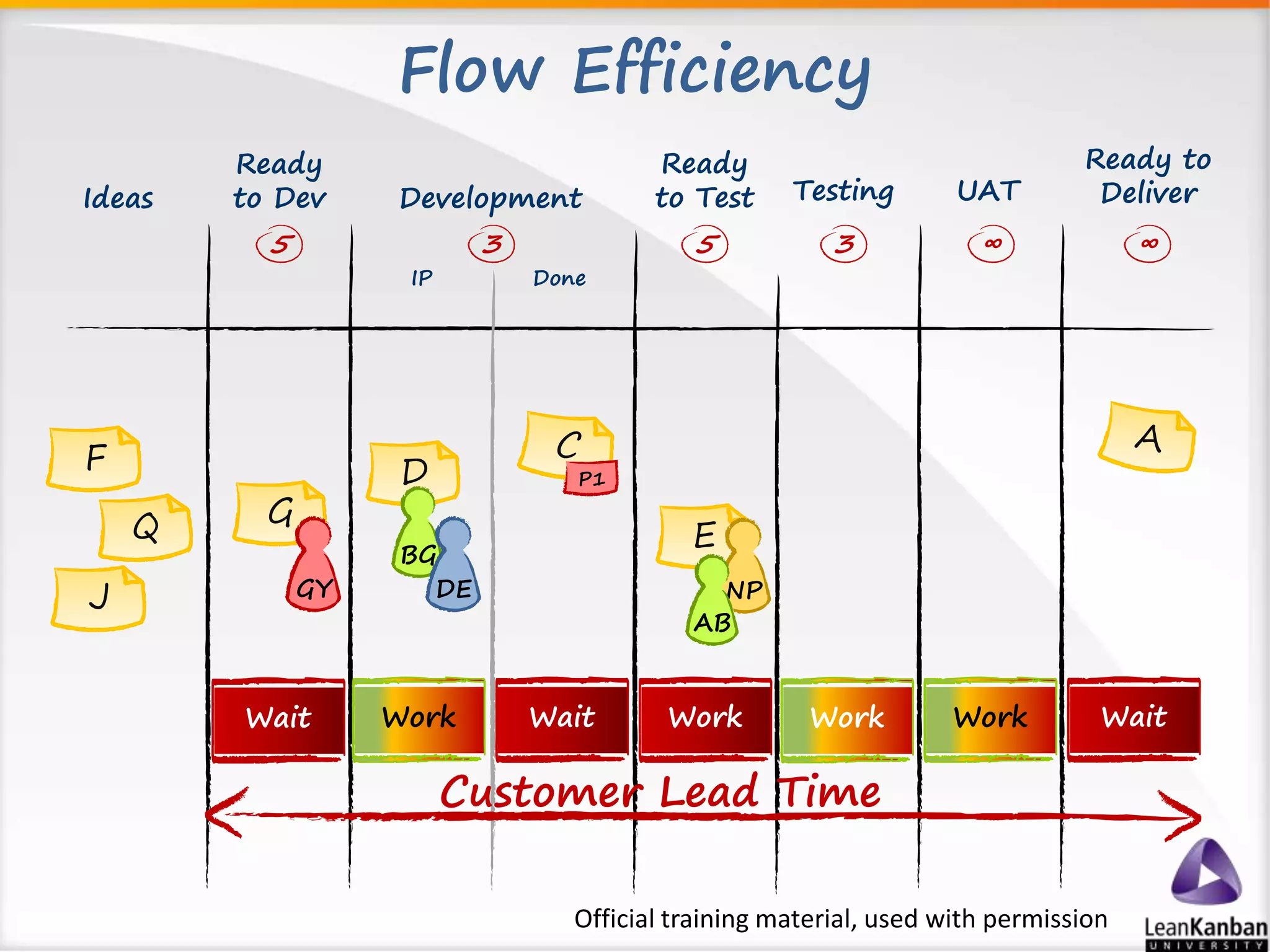

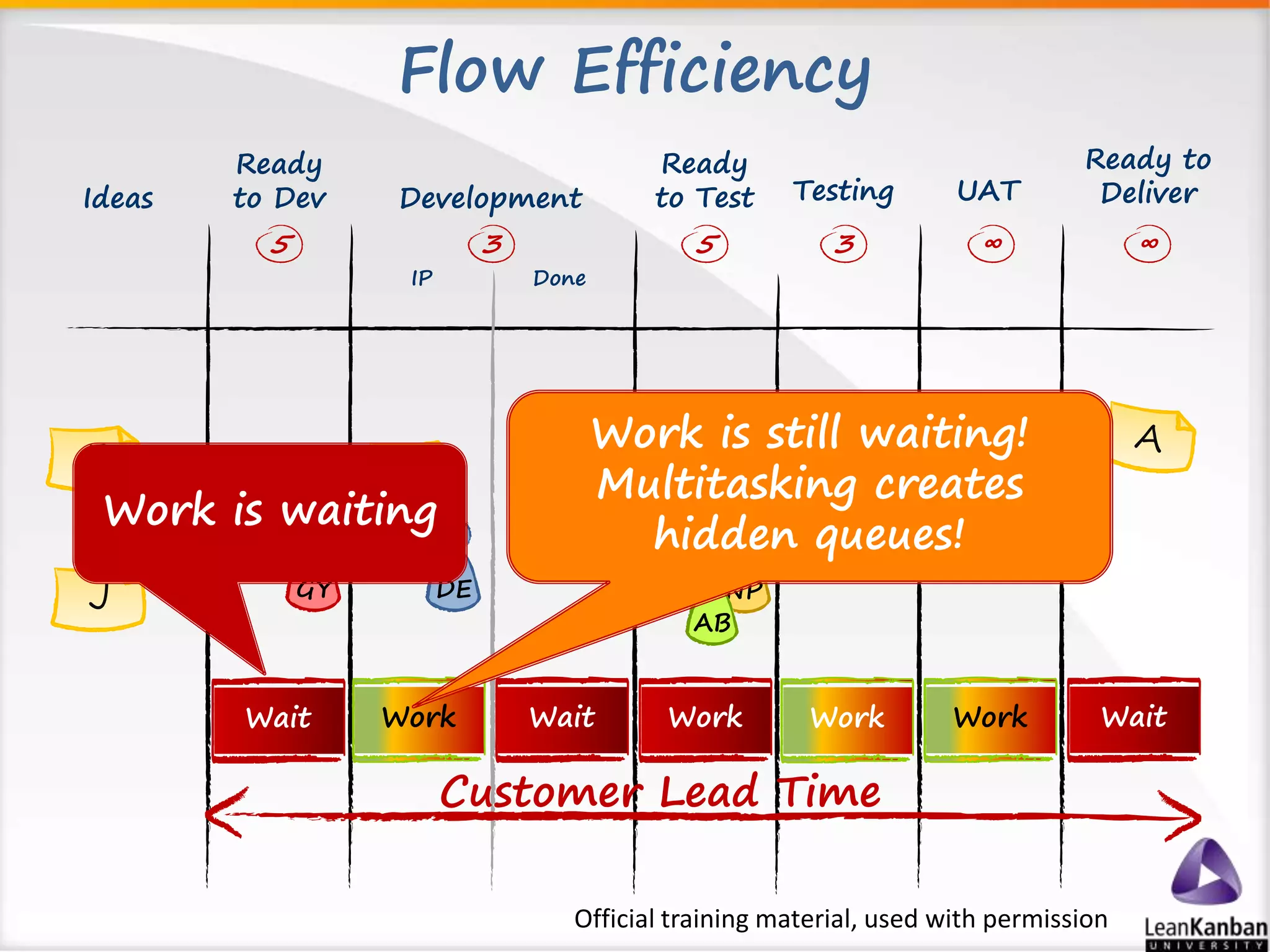

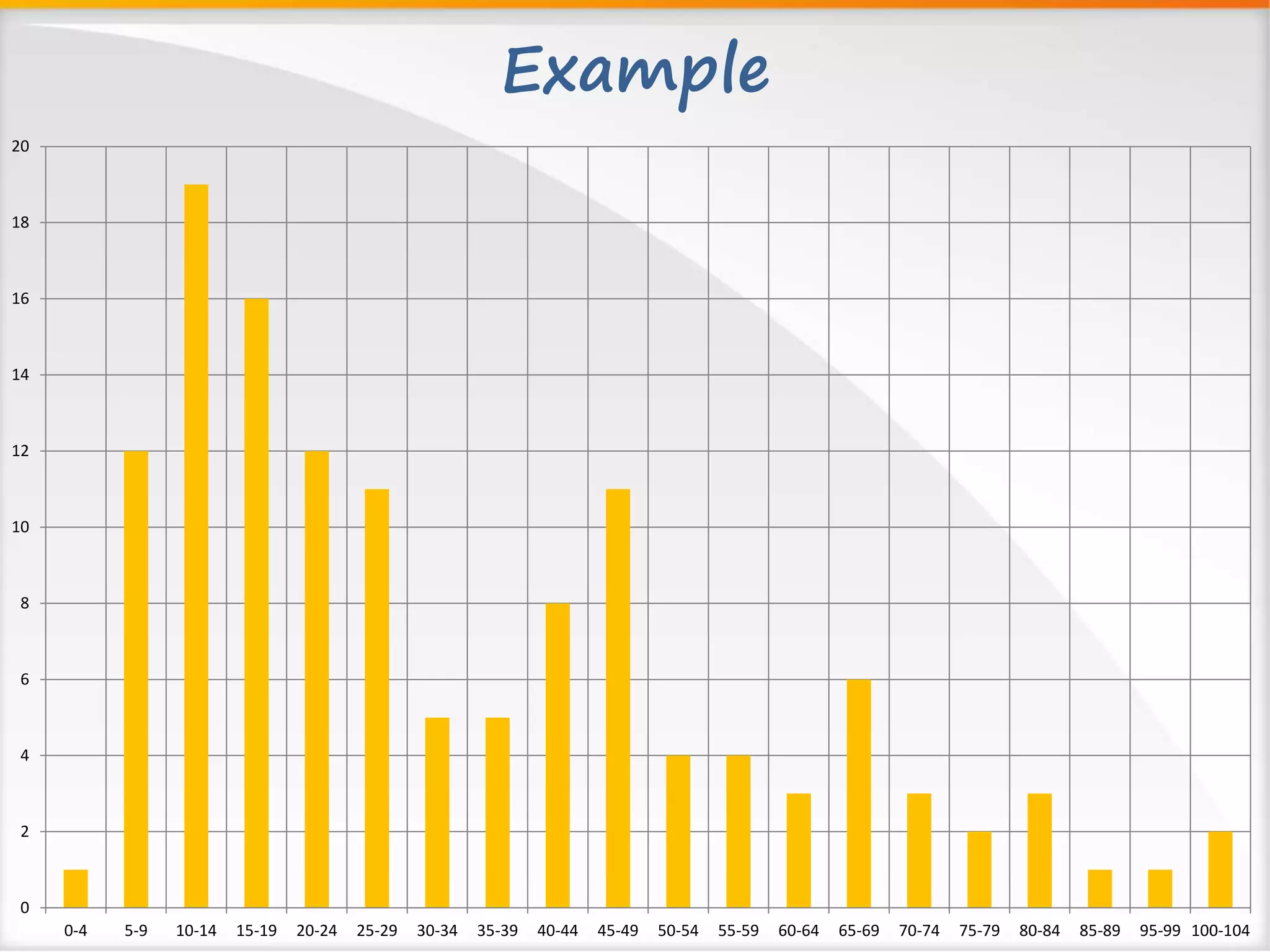

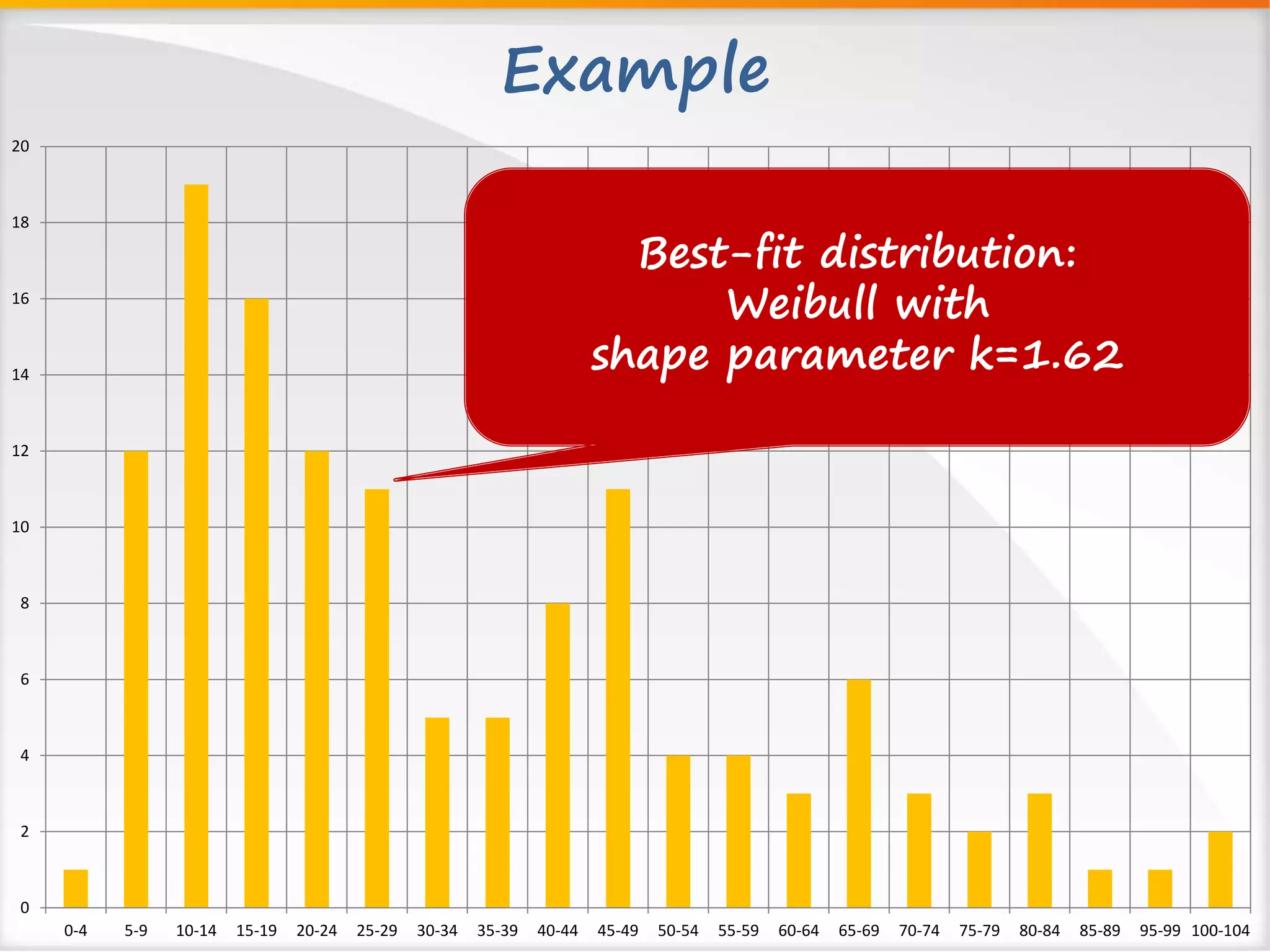

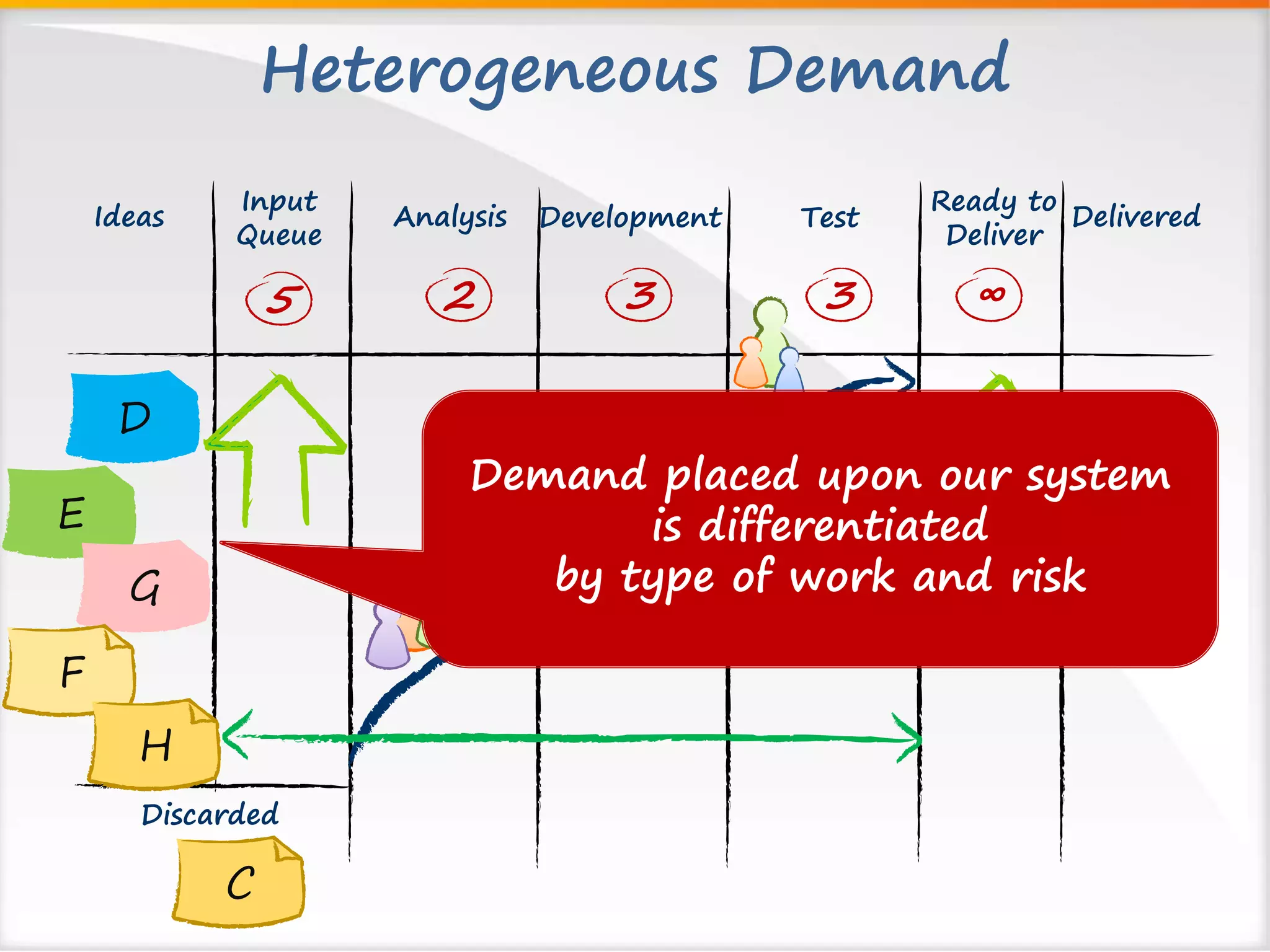

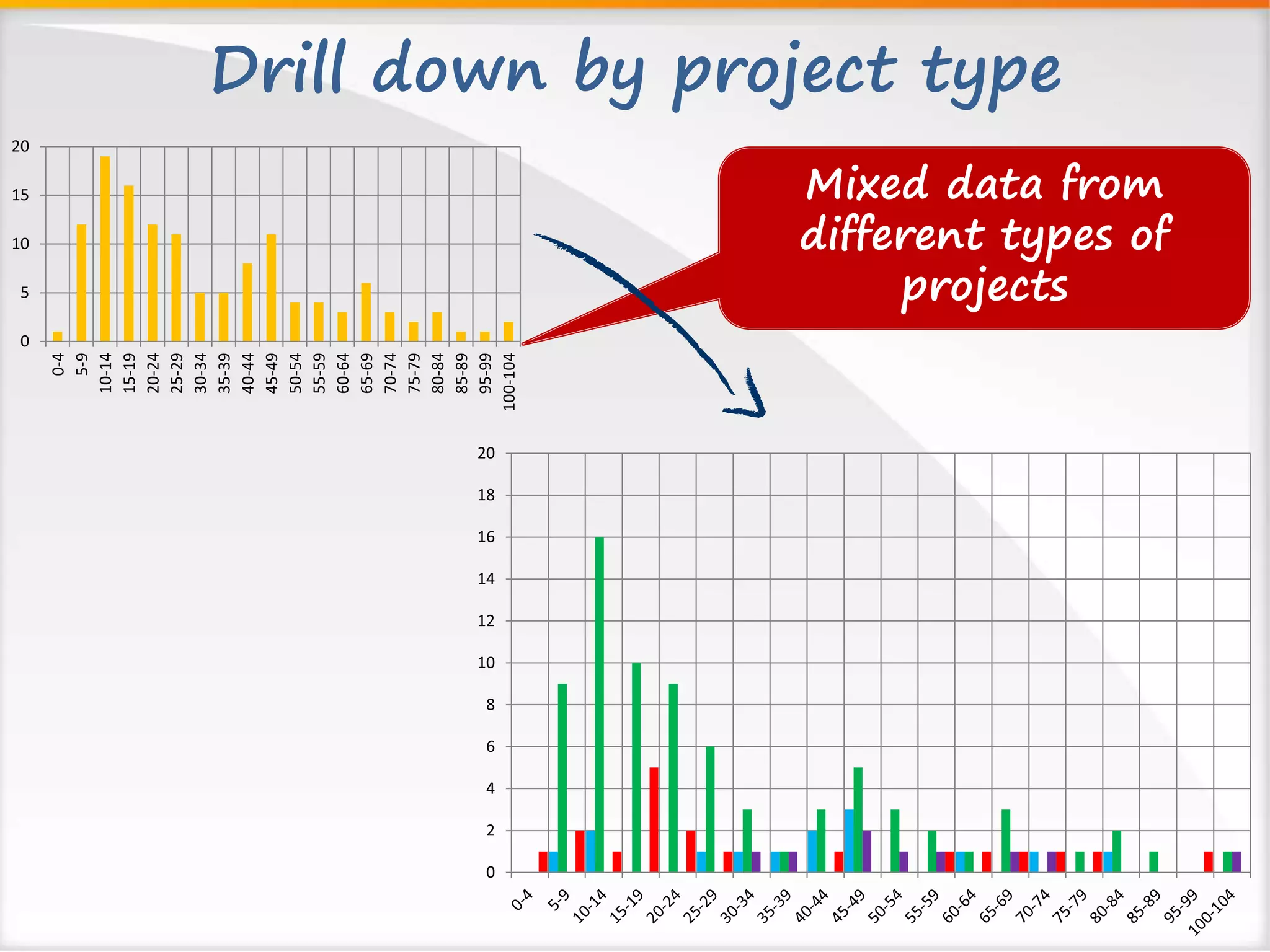

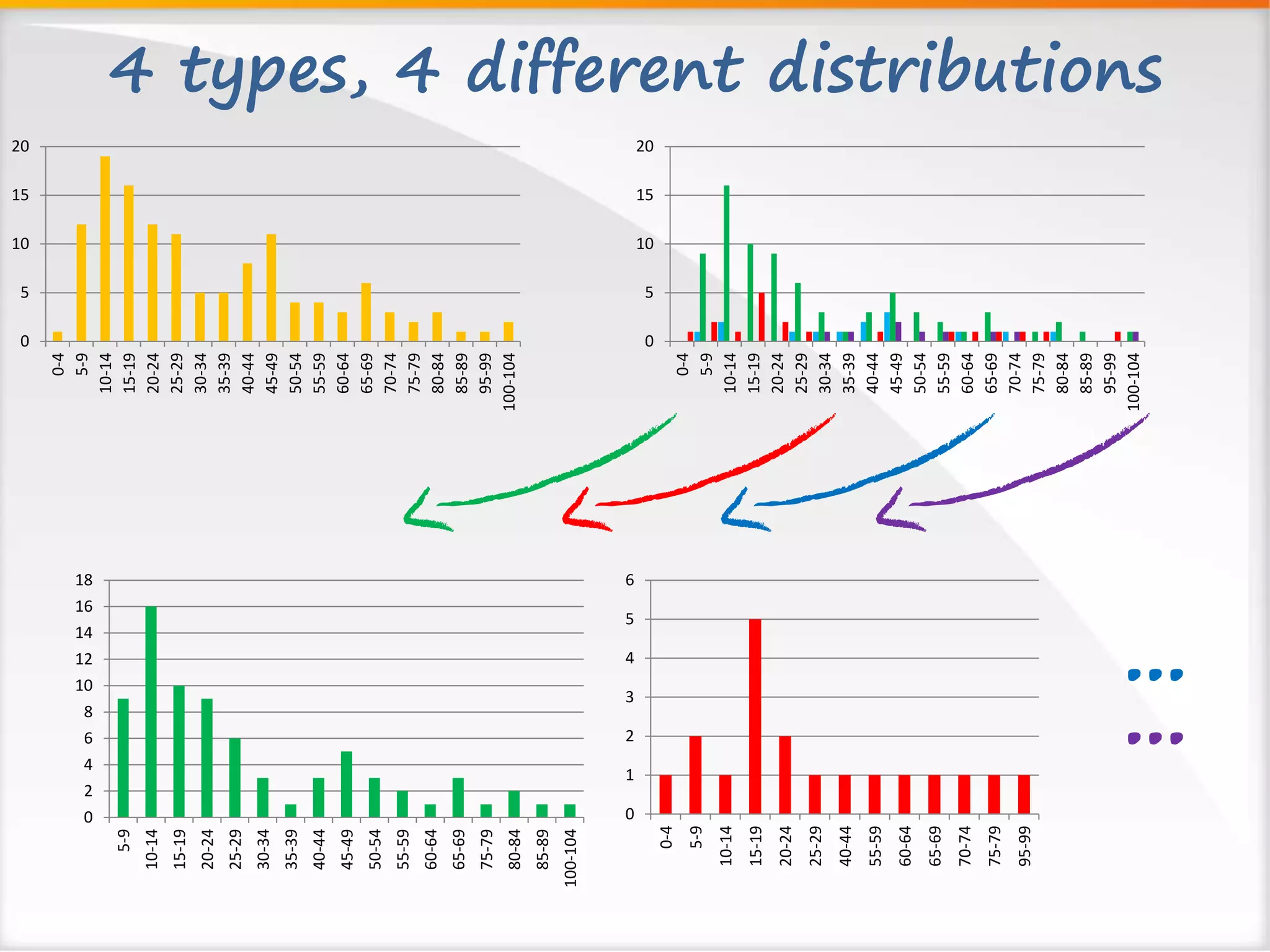

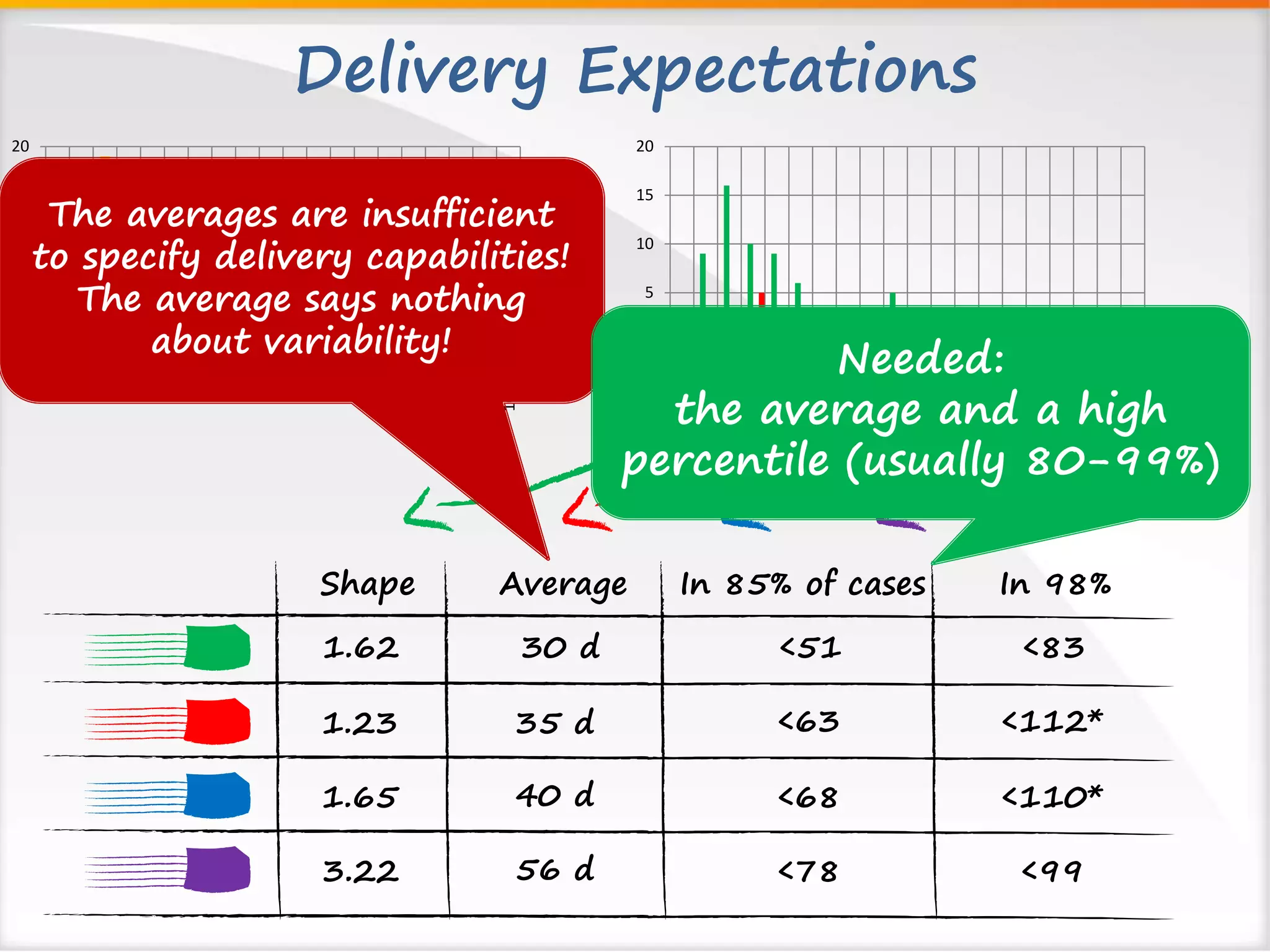

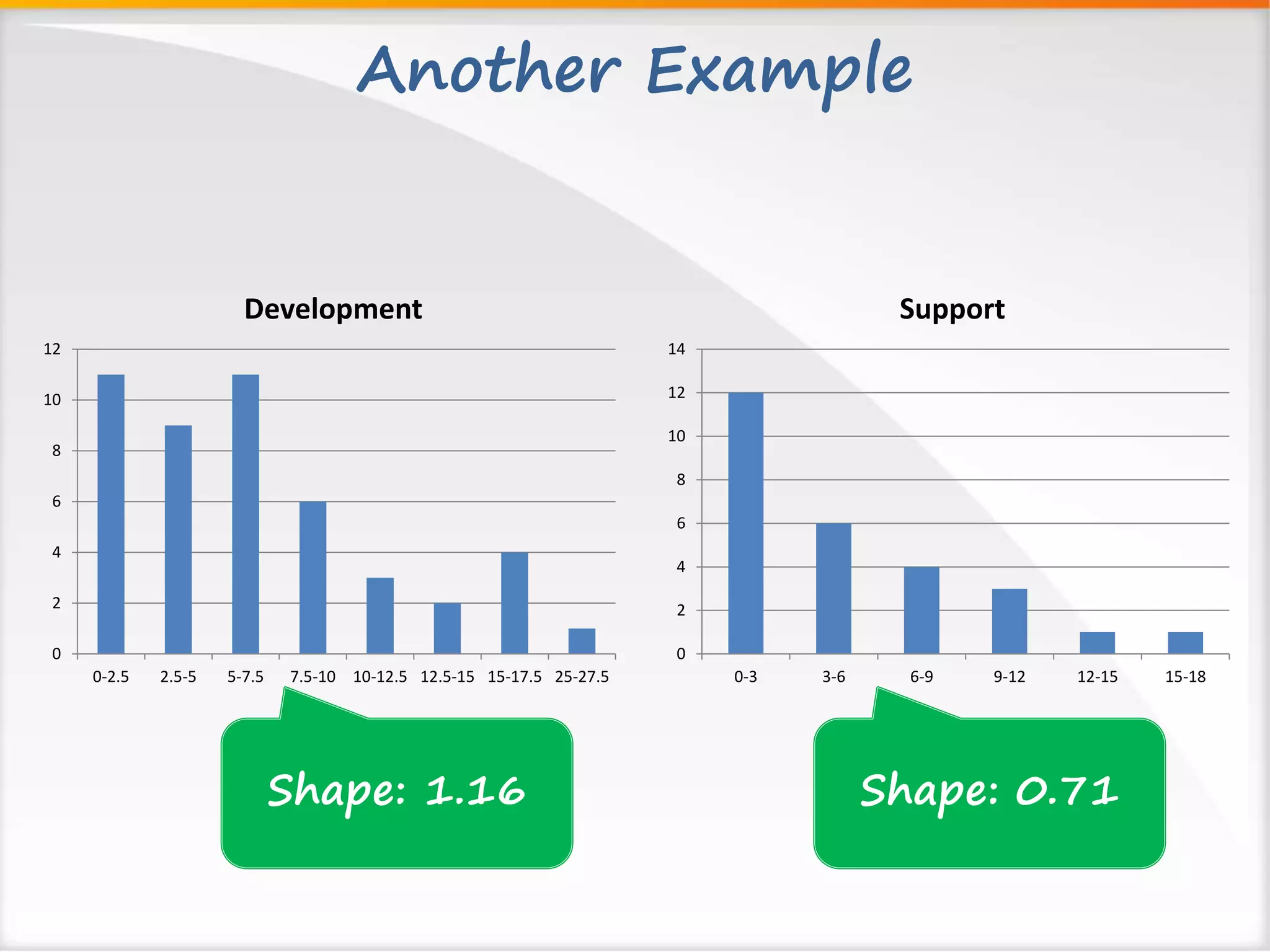

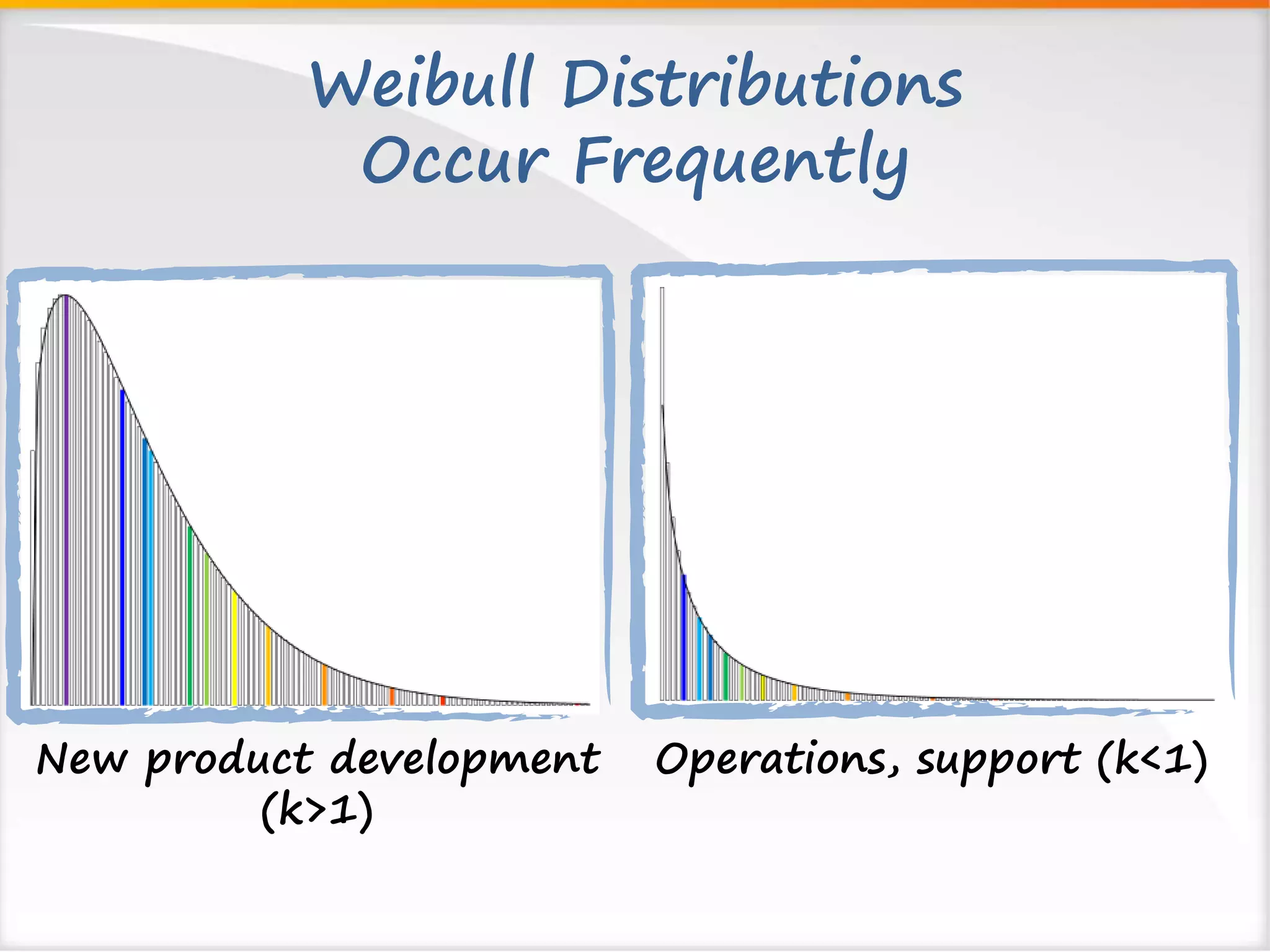

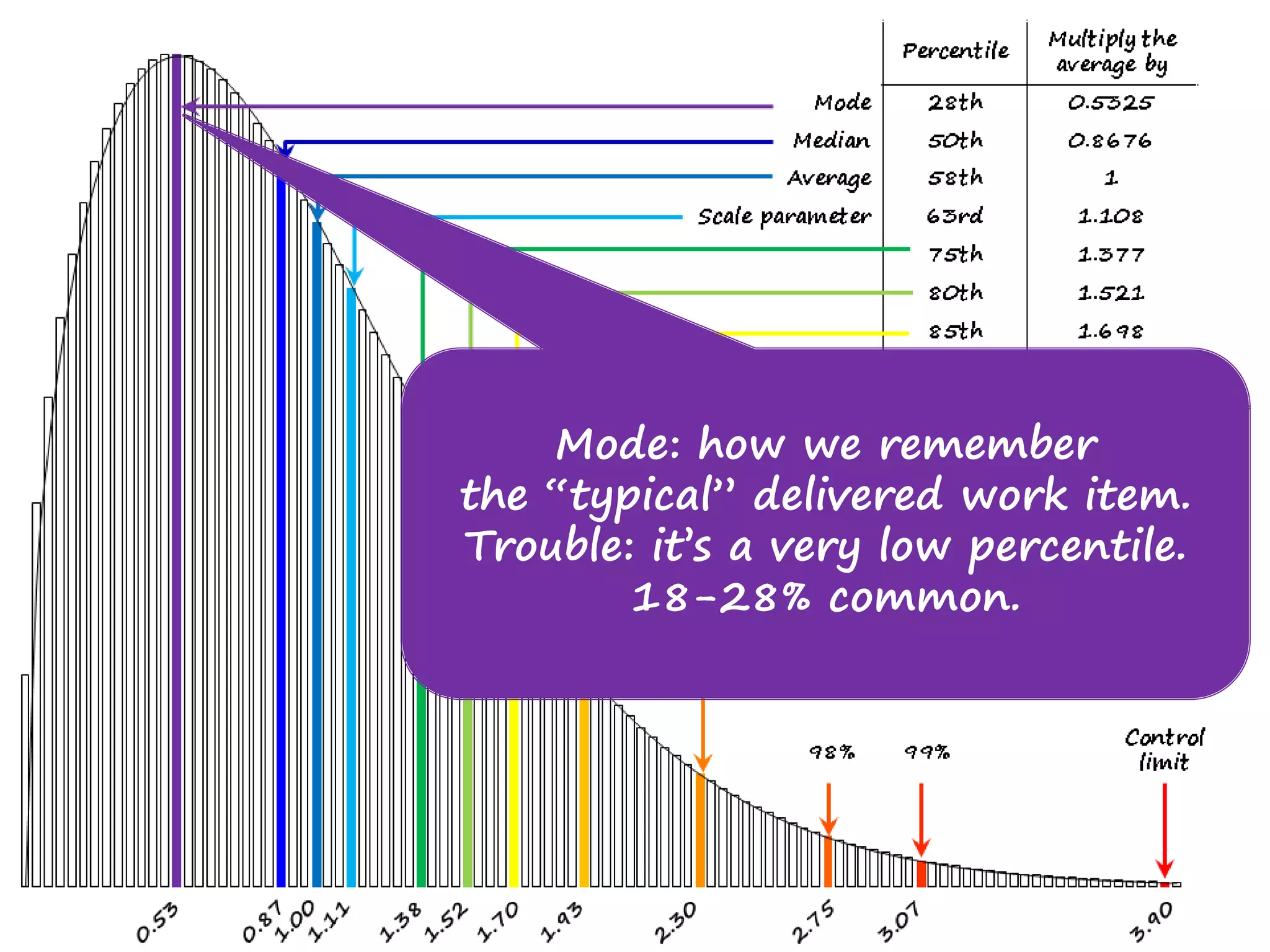

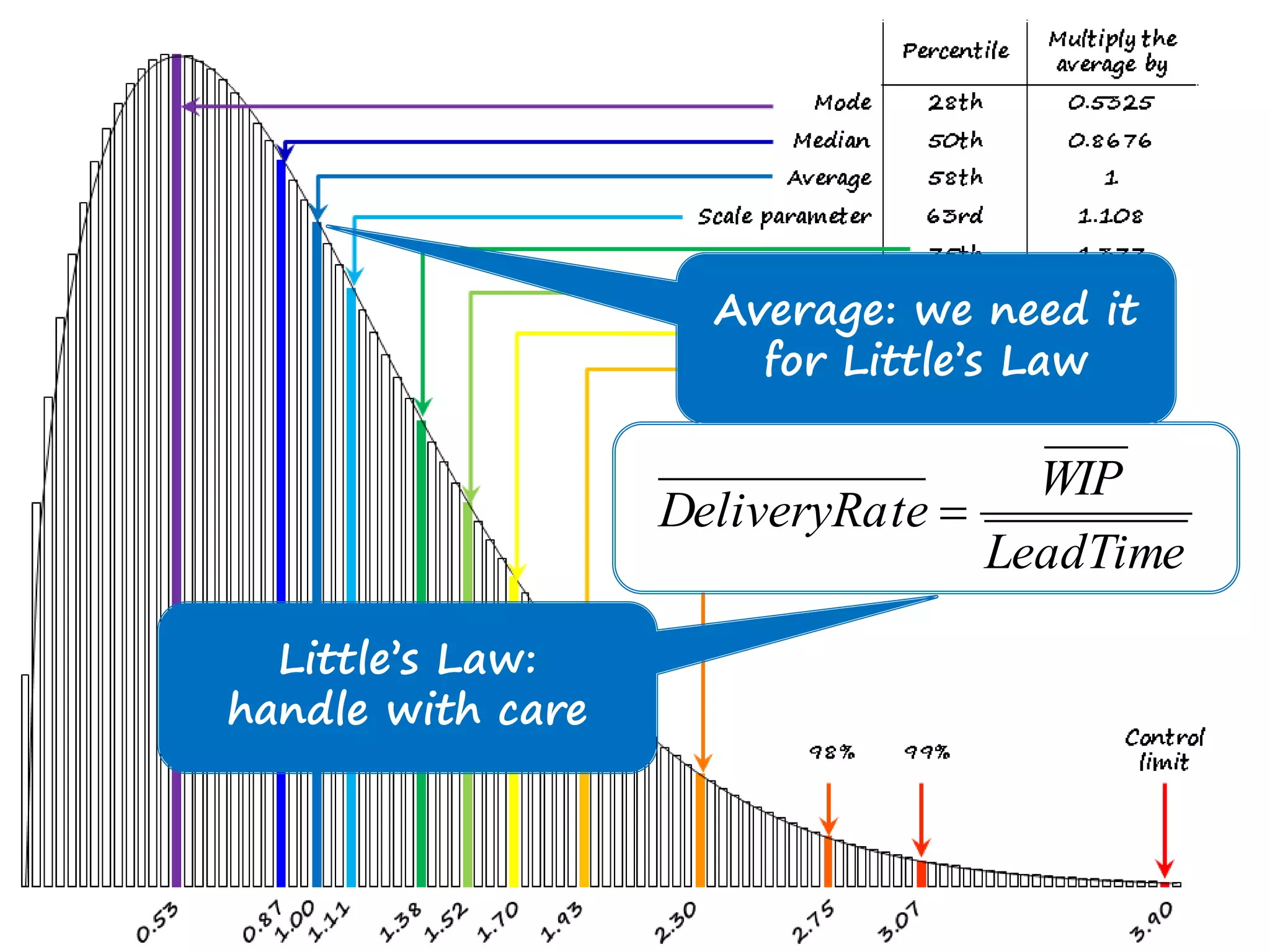

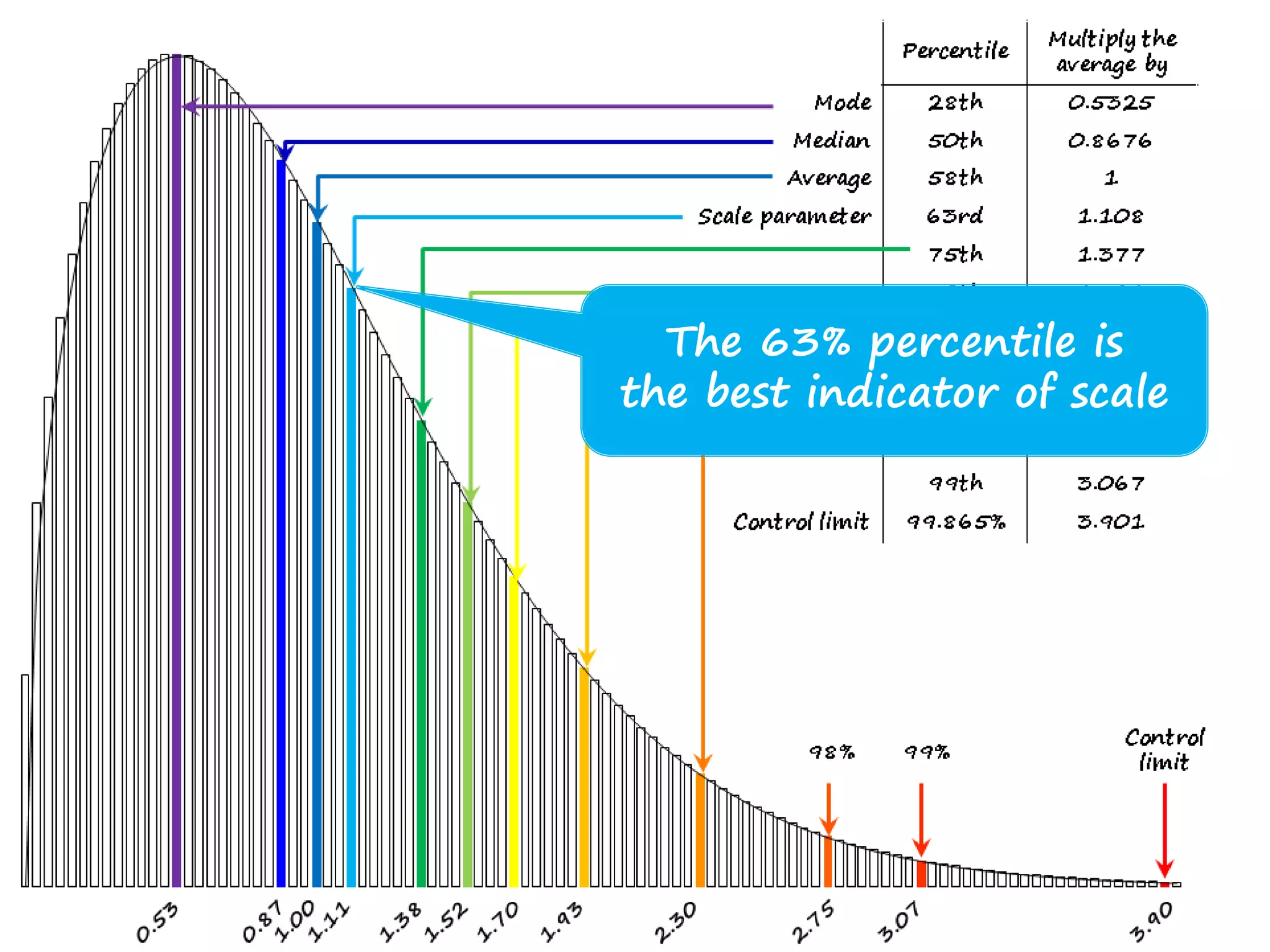

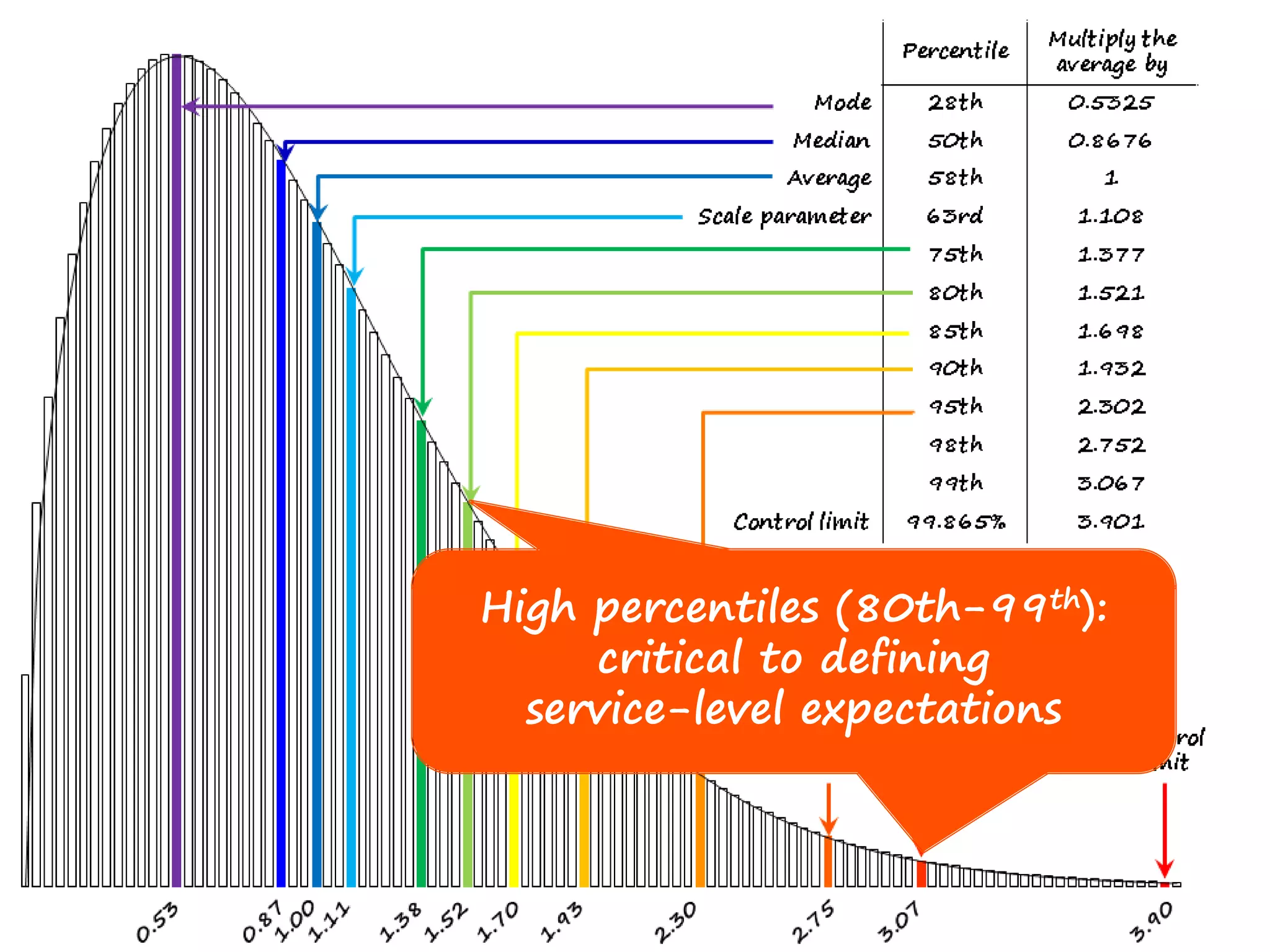

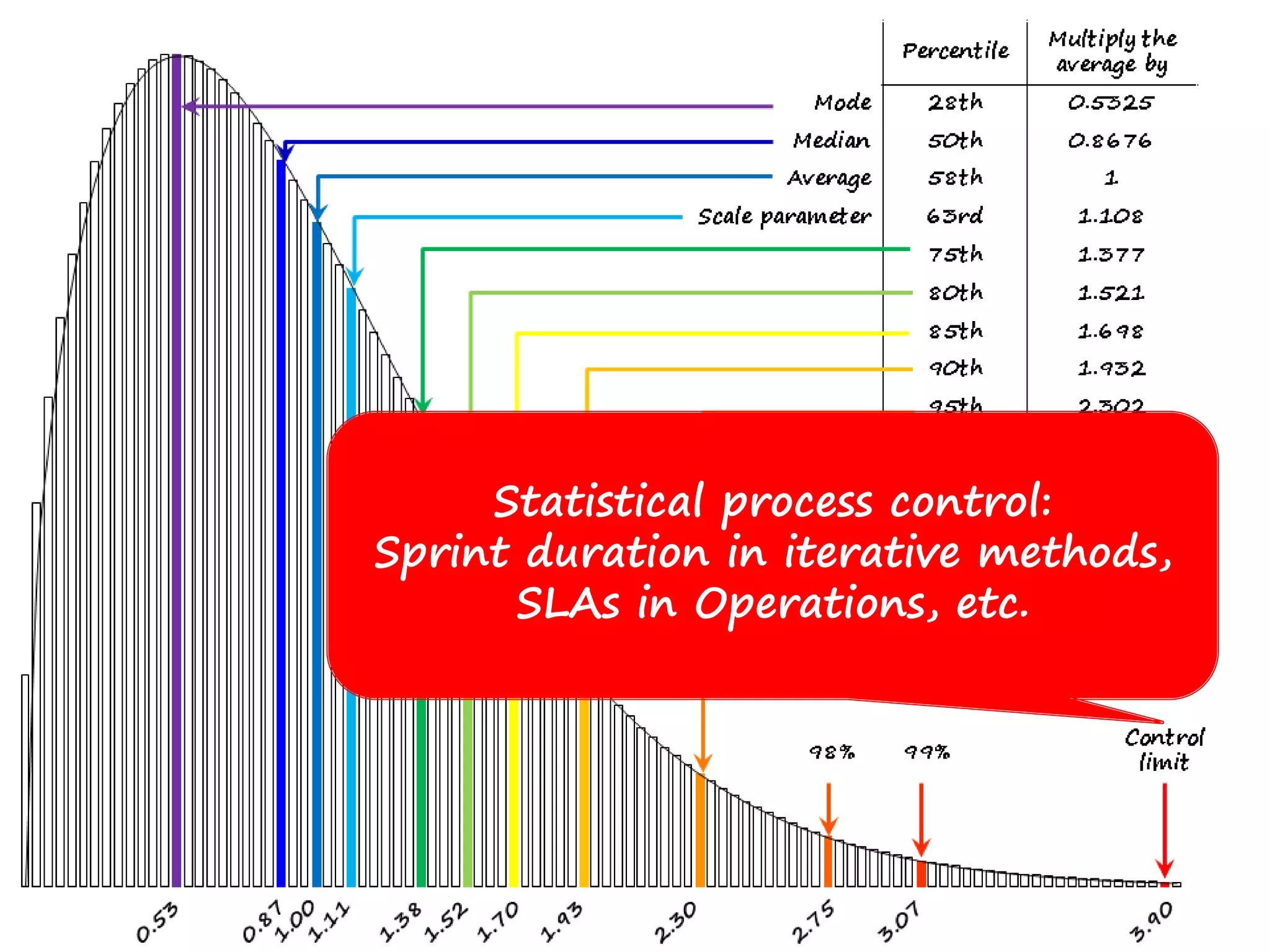

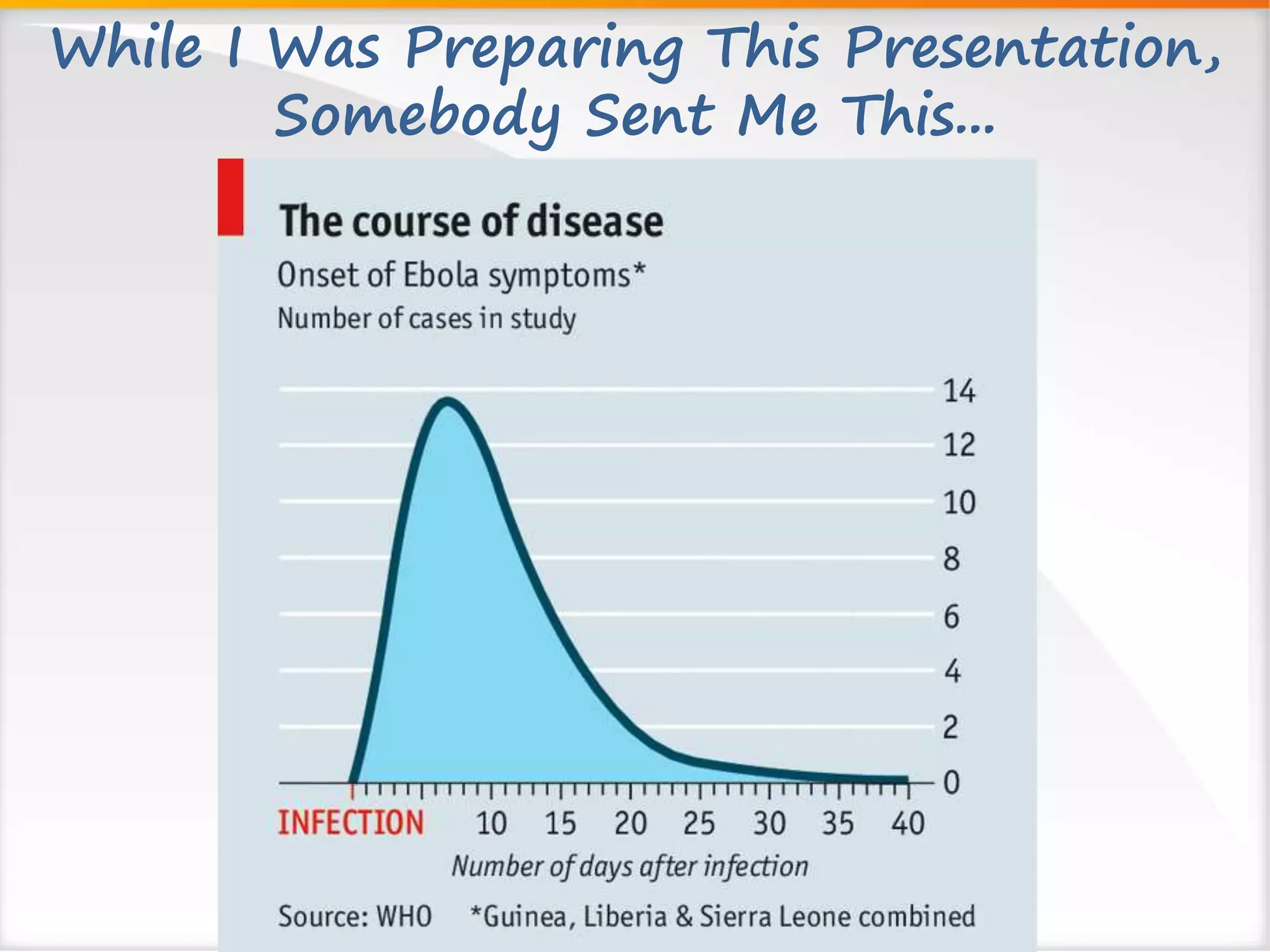

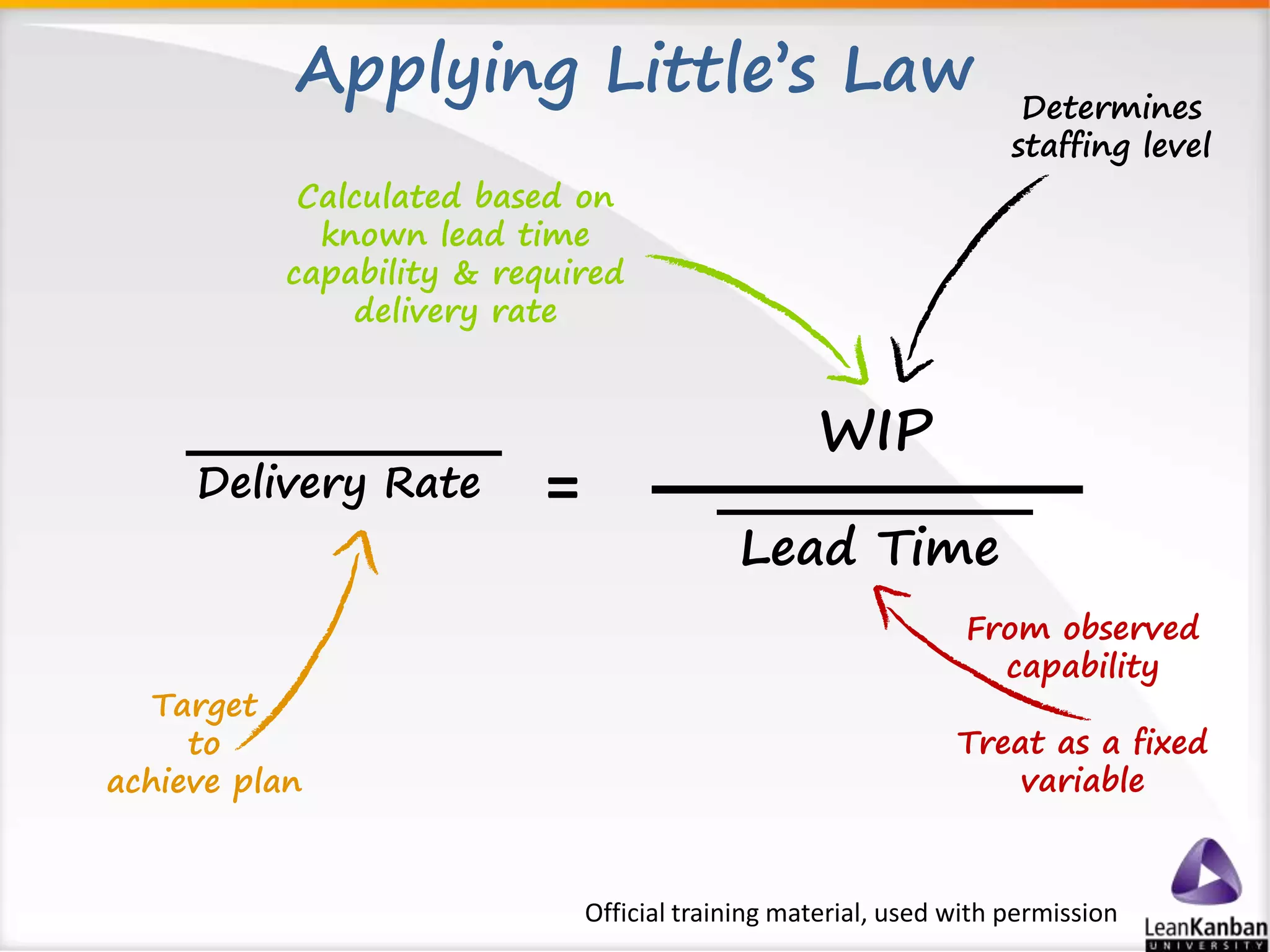

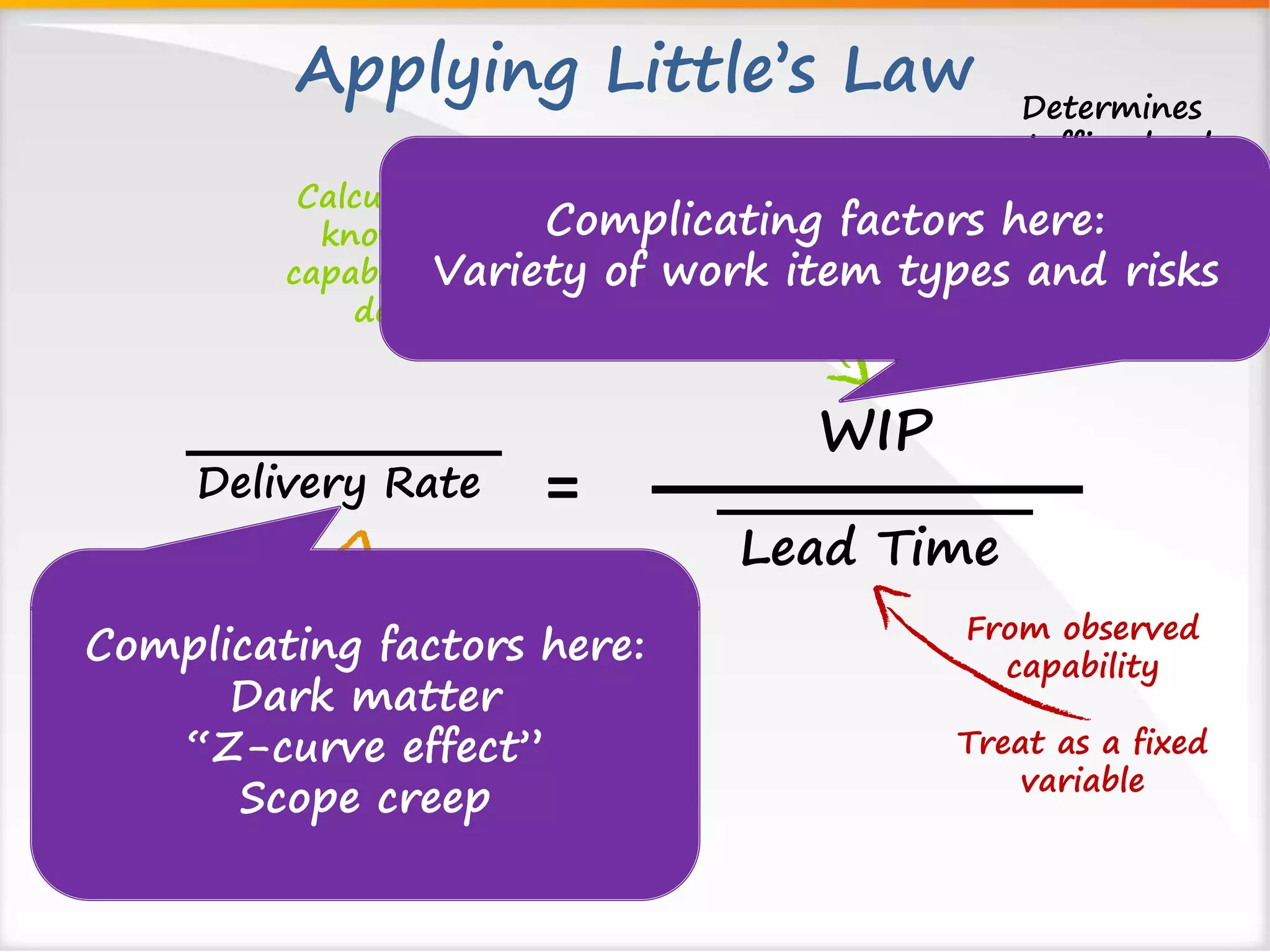

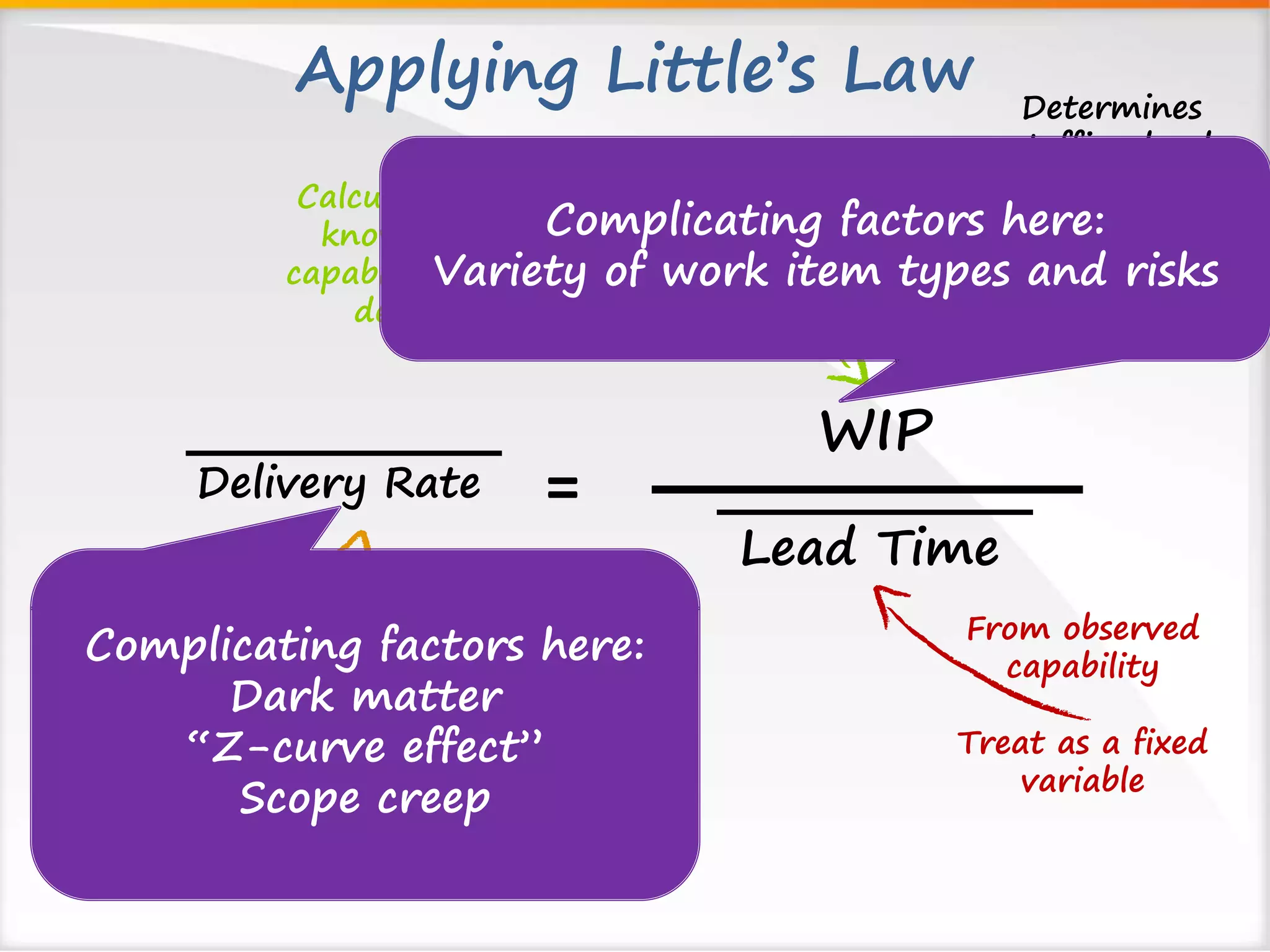

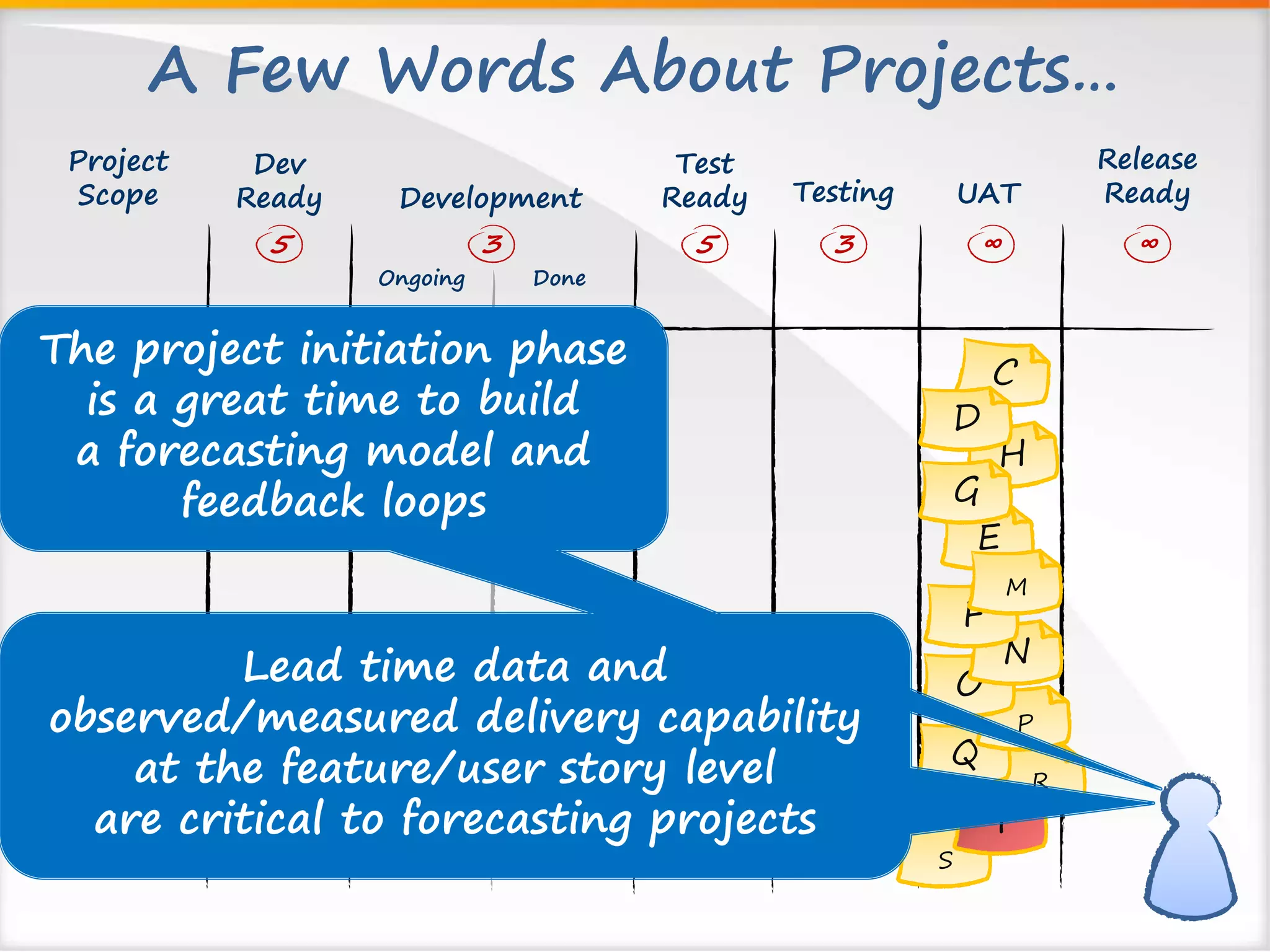

This document discusses lead time and how measuring and understanding it can help forecast projects. It defines lead time as the time between one event preceding another. Lead time data can be more useful than just average times since it accounts for variability. The document also discusses using distributions to model different types of work instead of single numbers, as processes are probabilistic rather than deterministic. Measuring lead time and understanding its distribution is important for planning delivery rates and work in process.