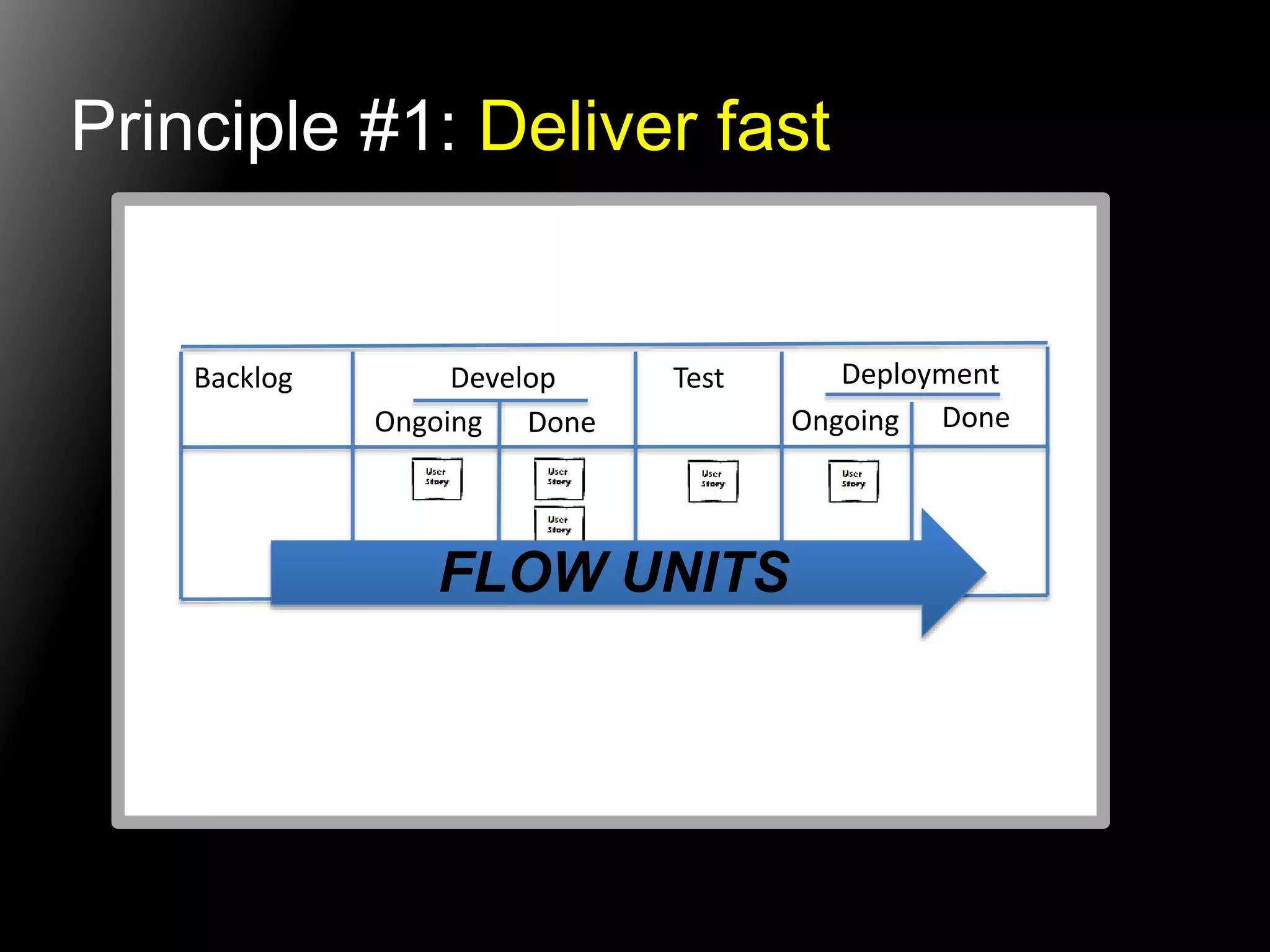

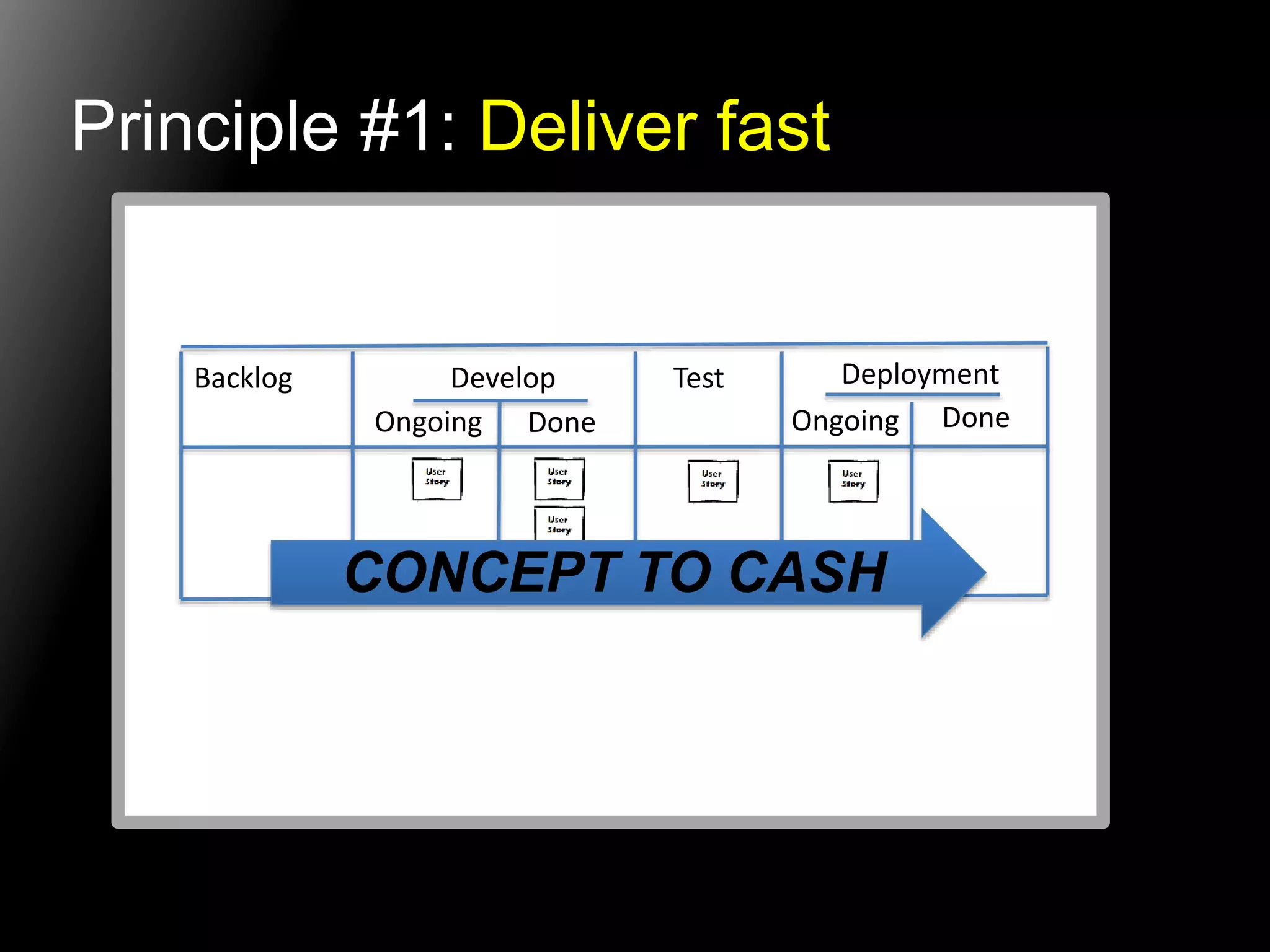

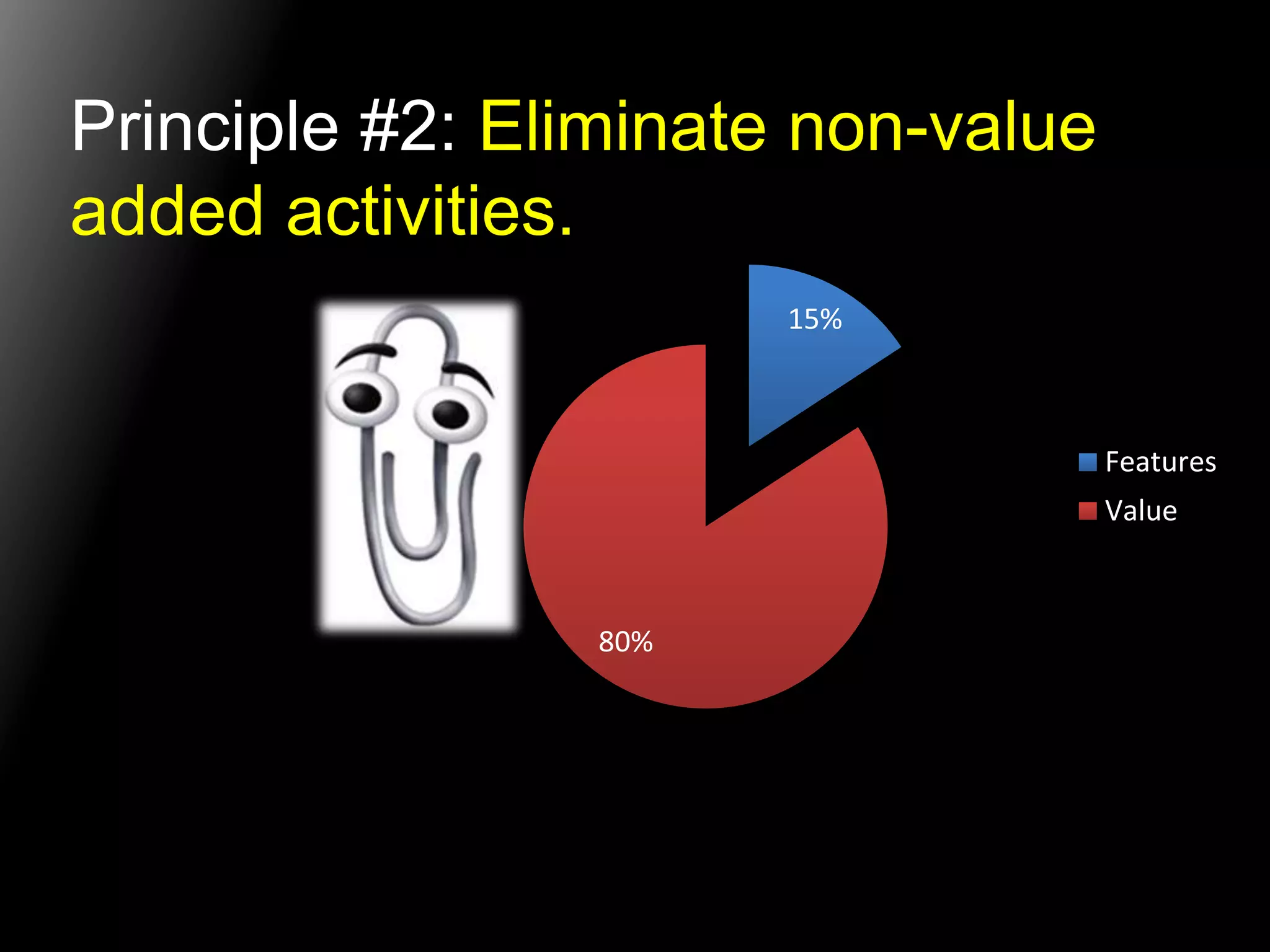

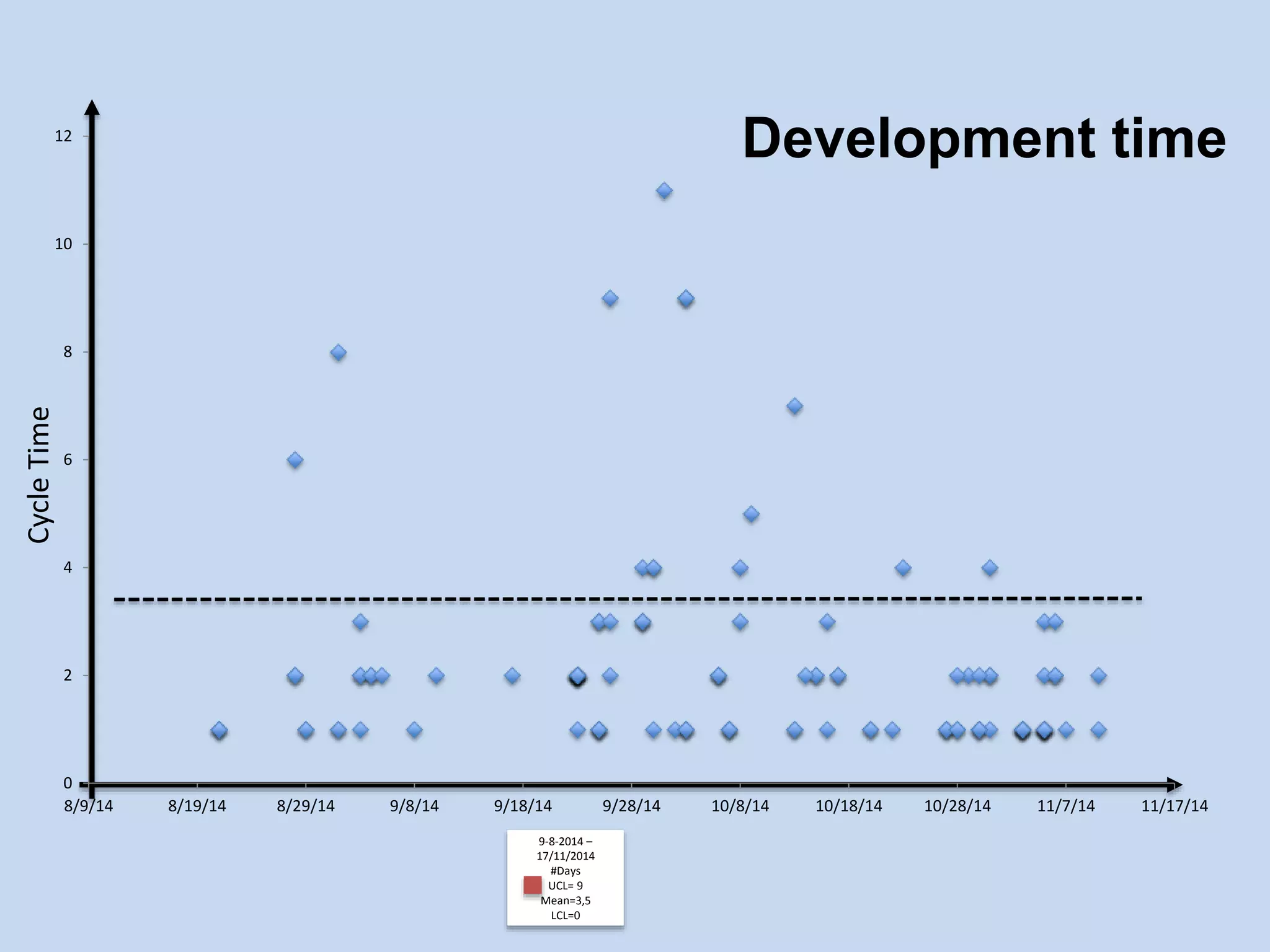

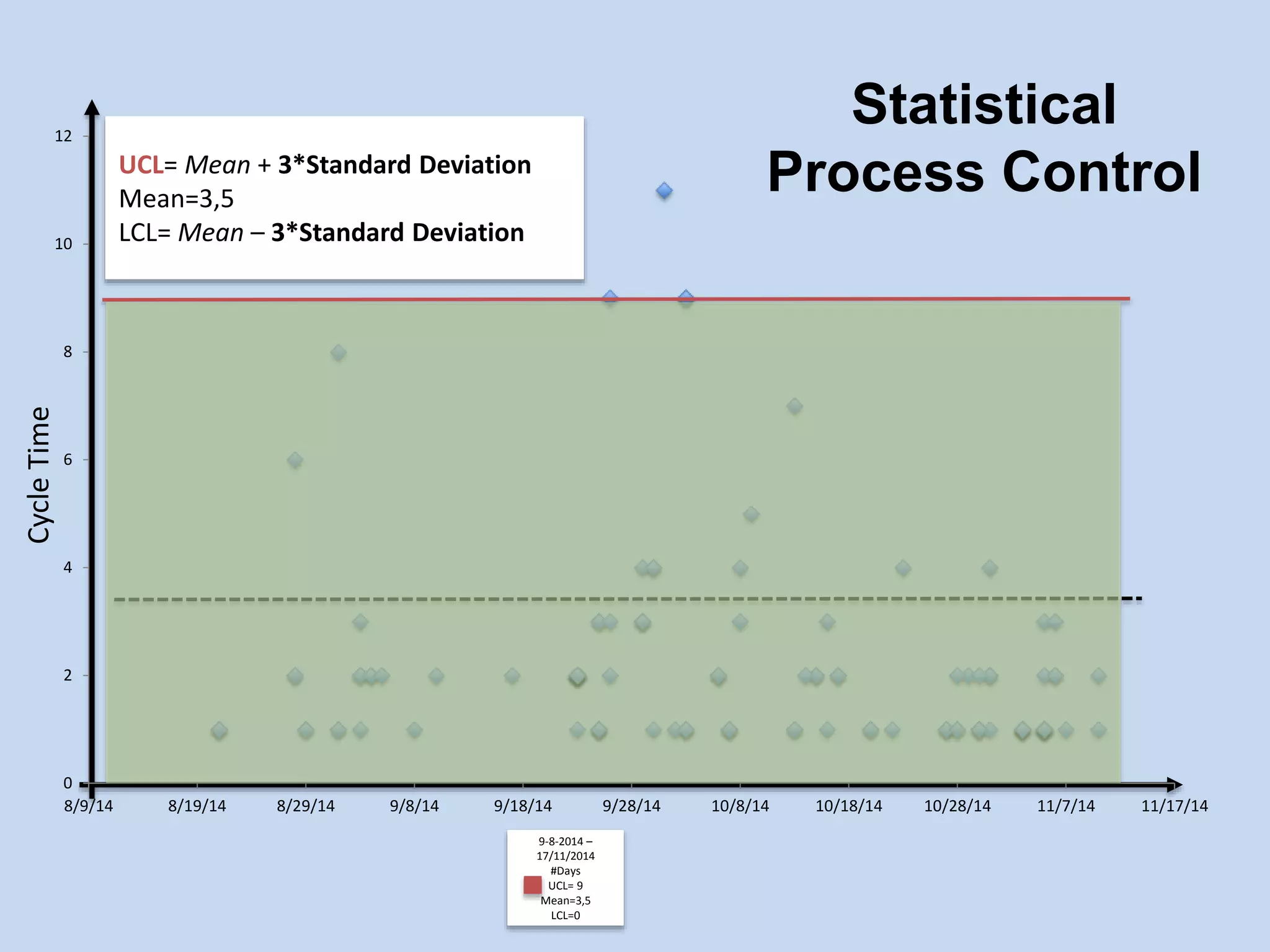

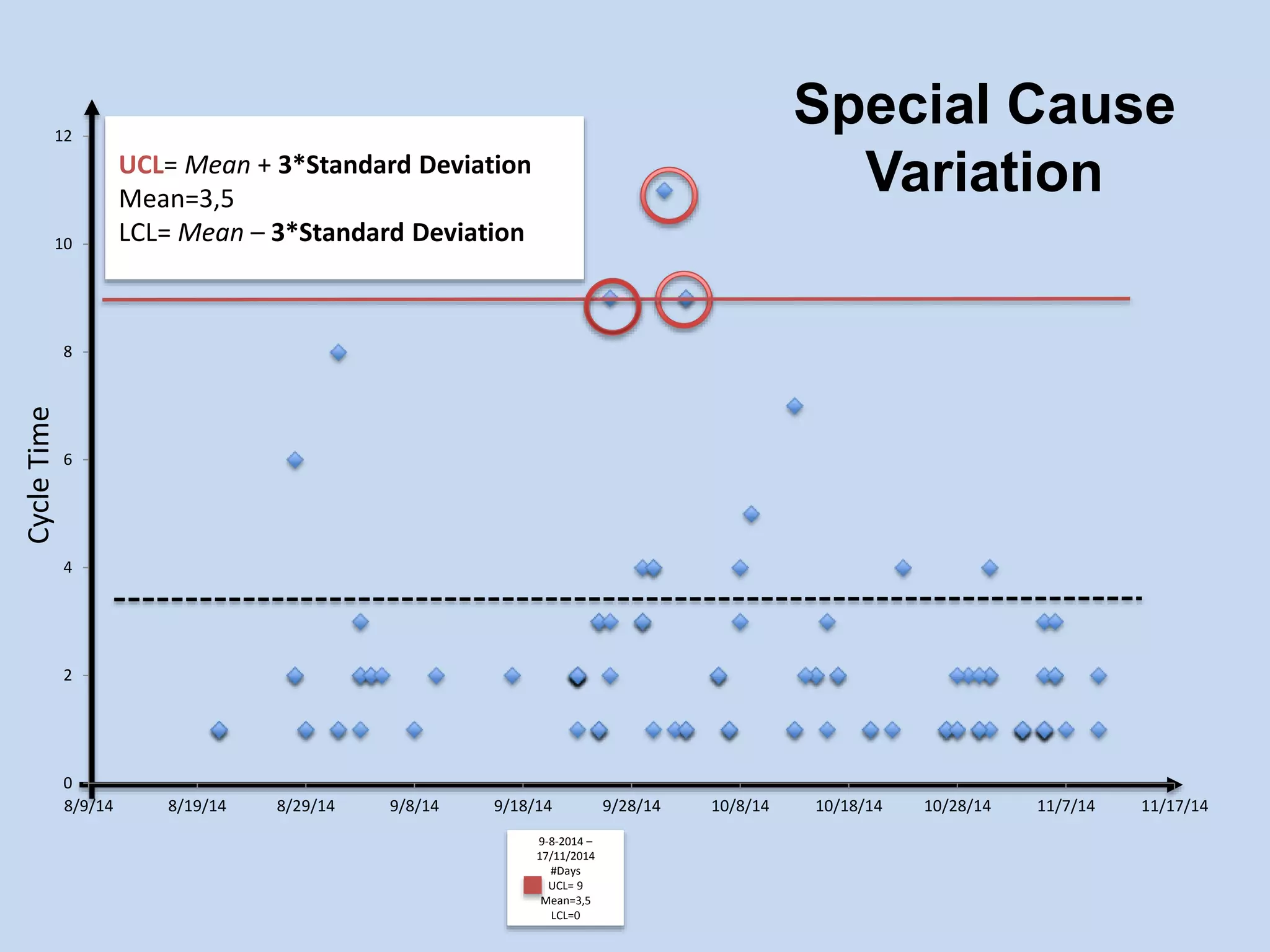

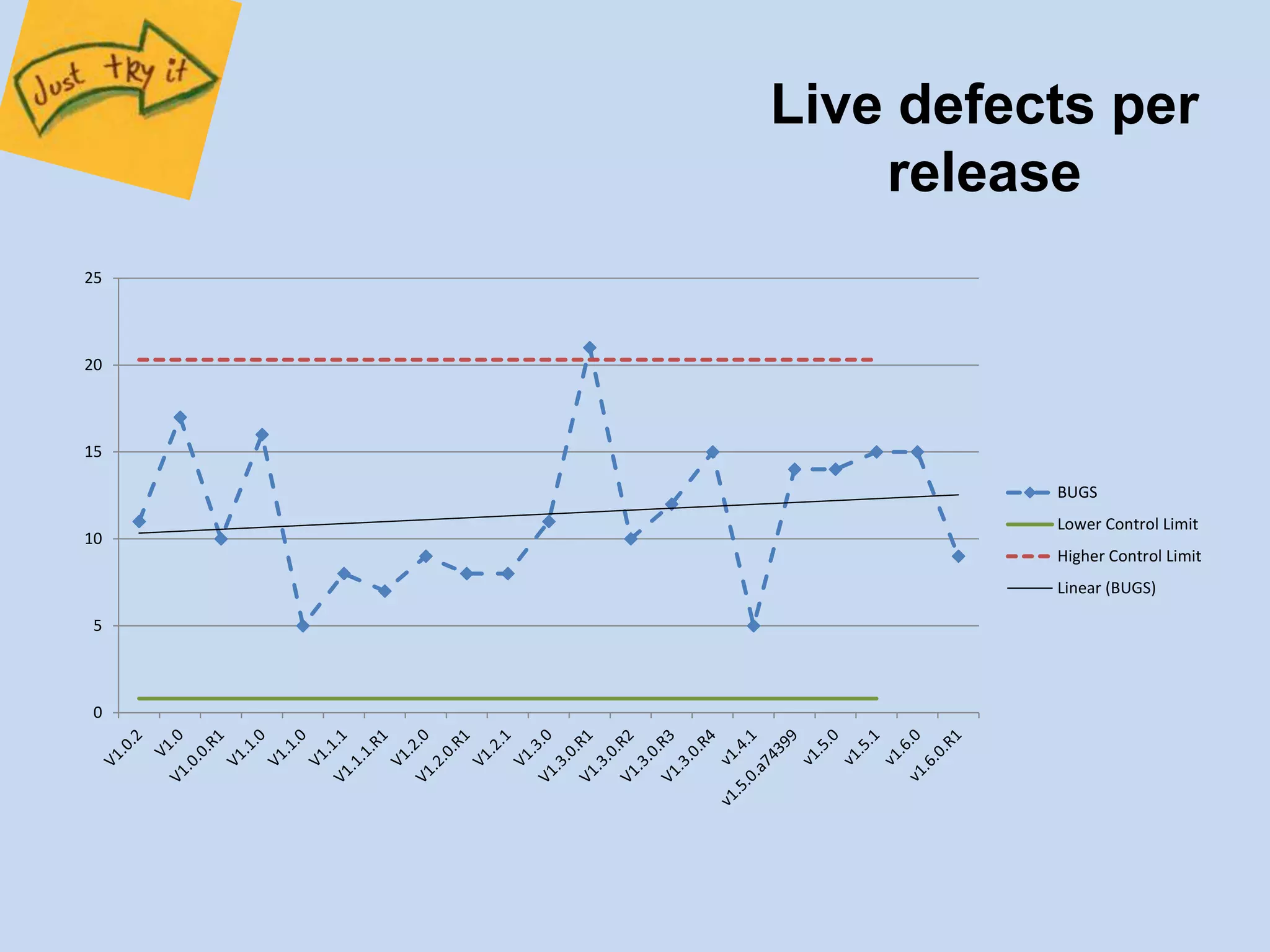

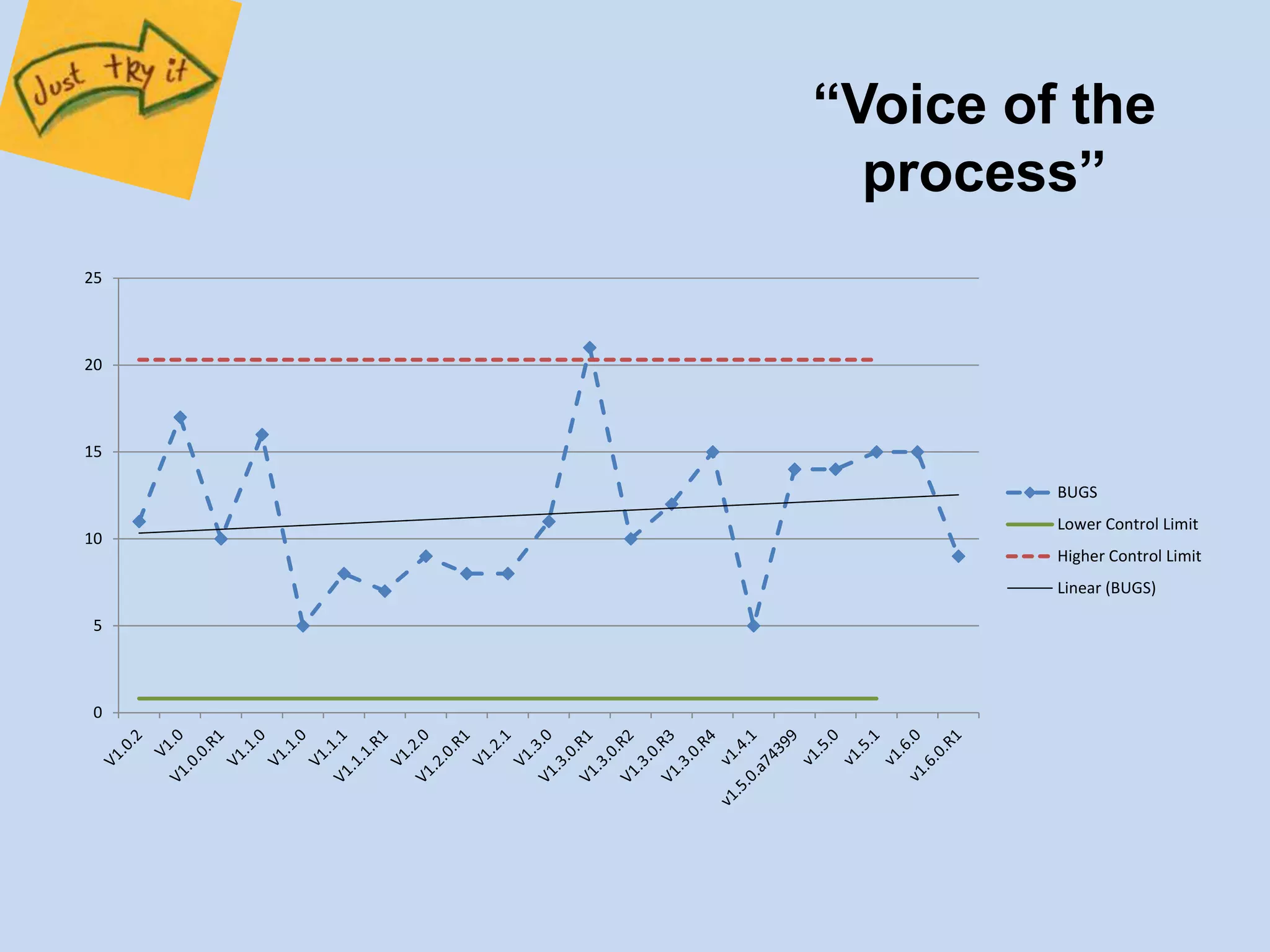

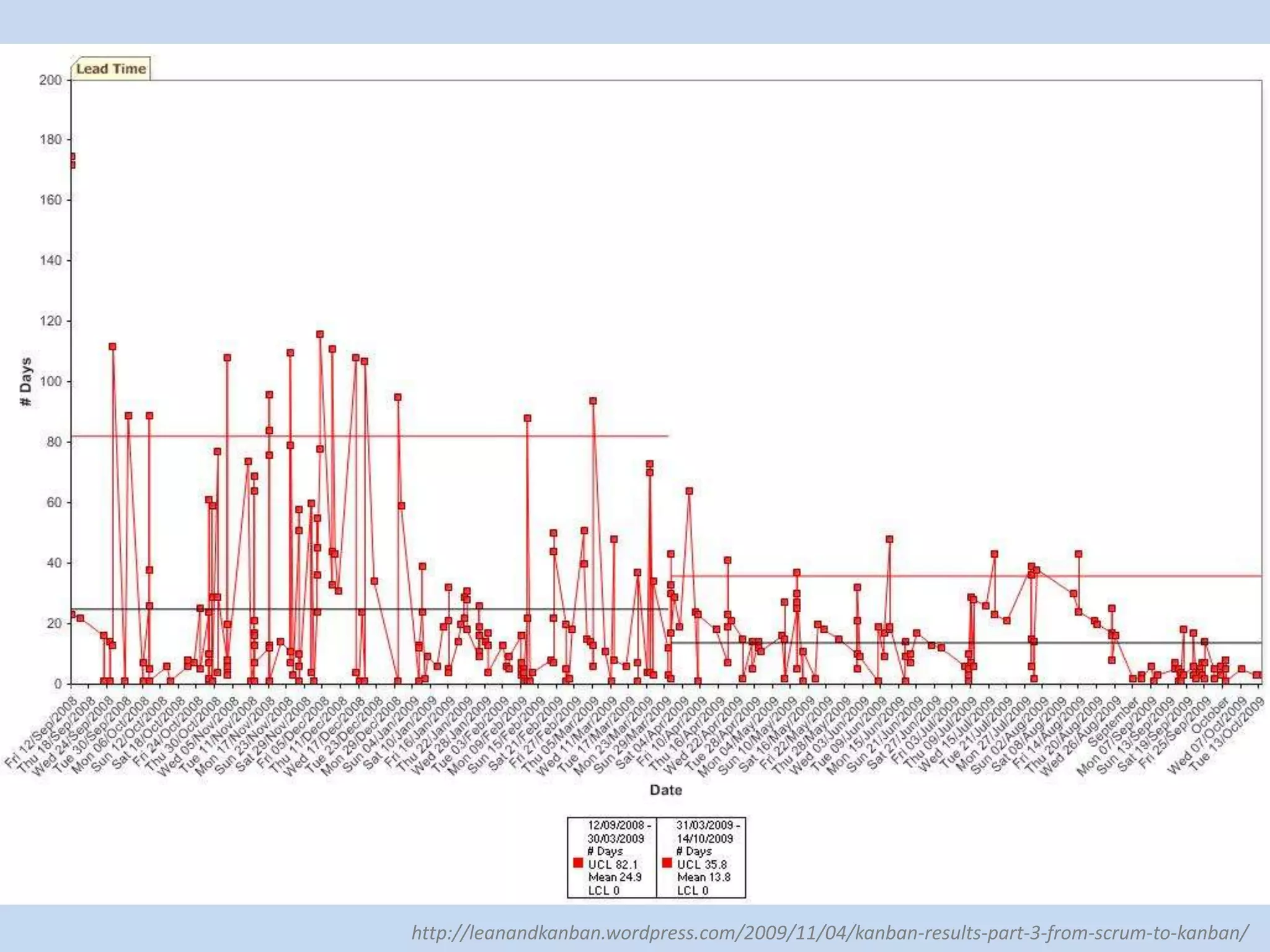

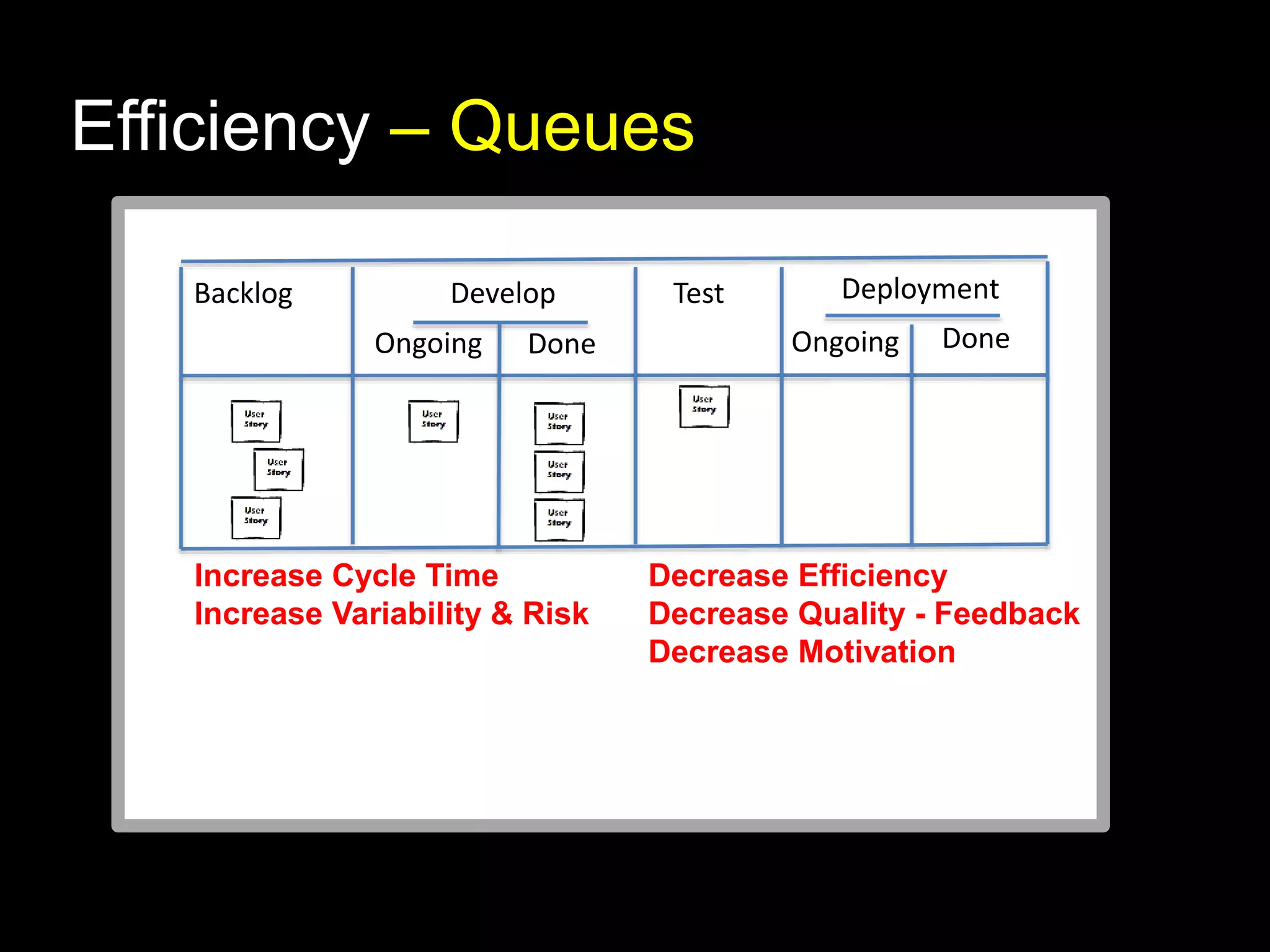

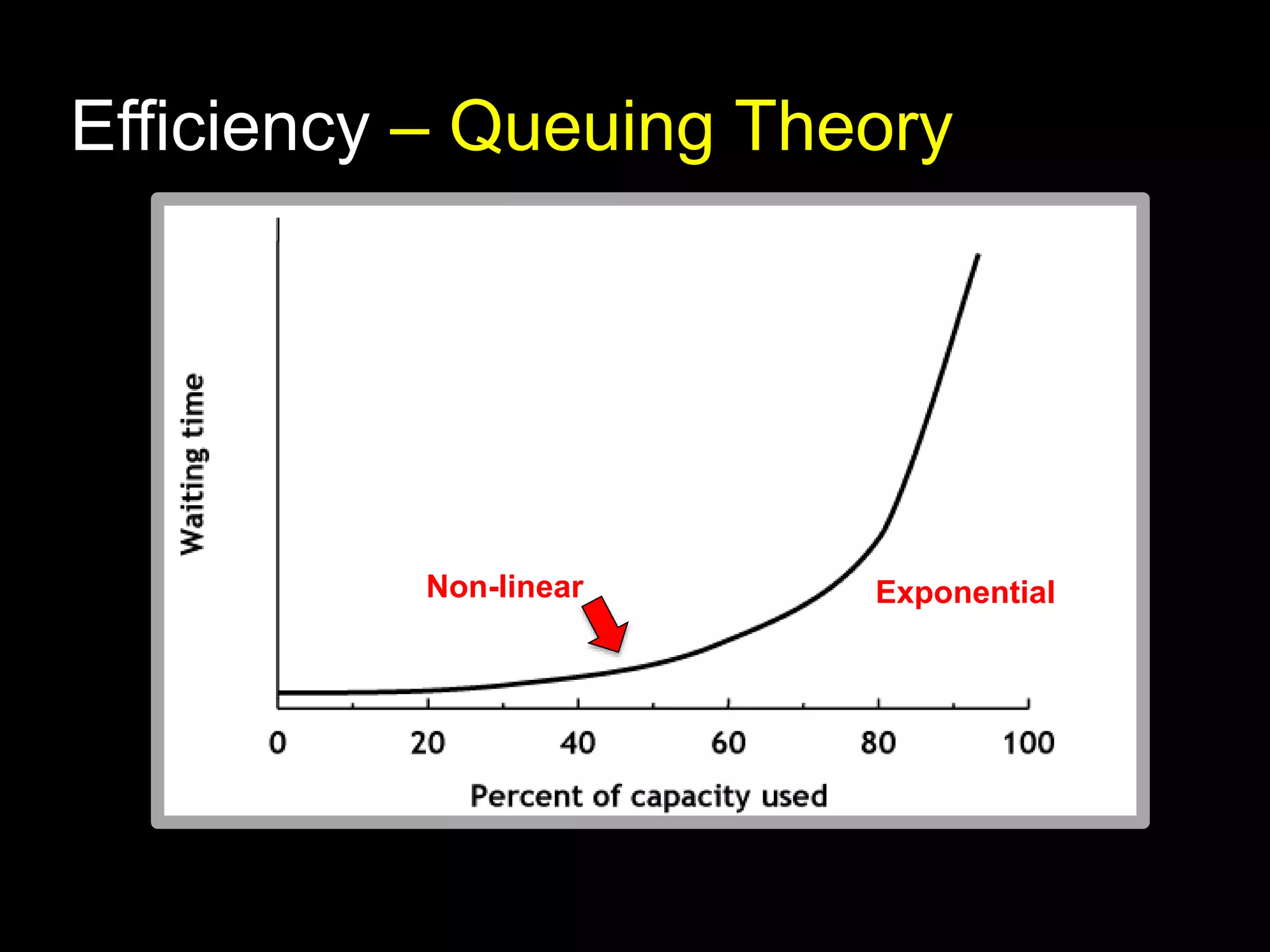

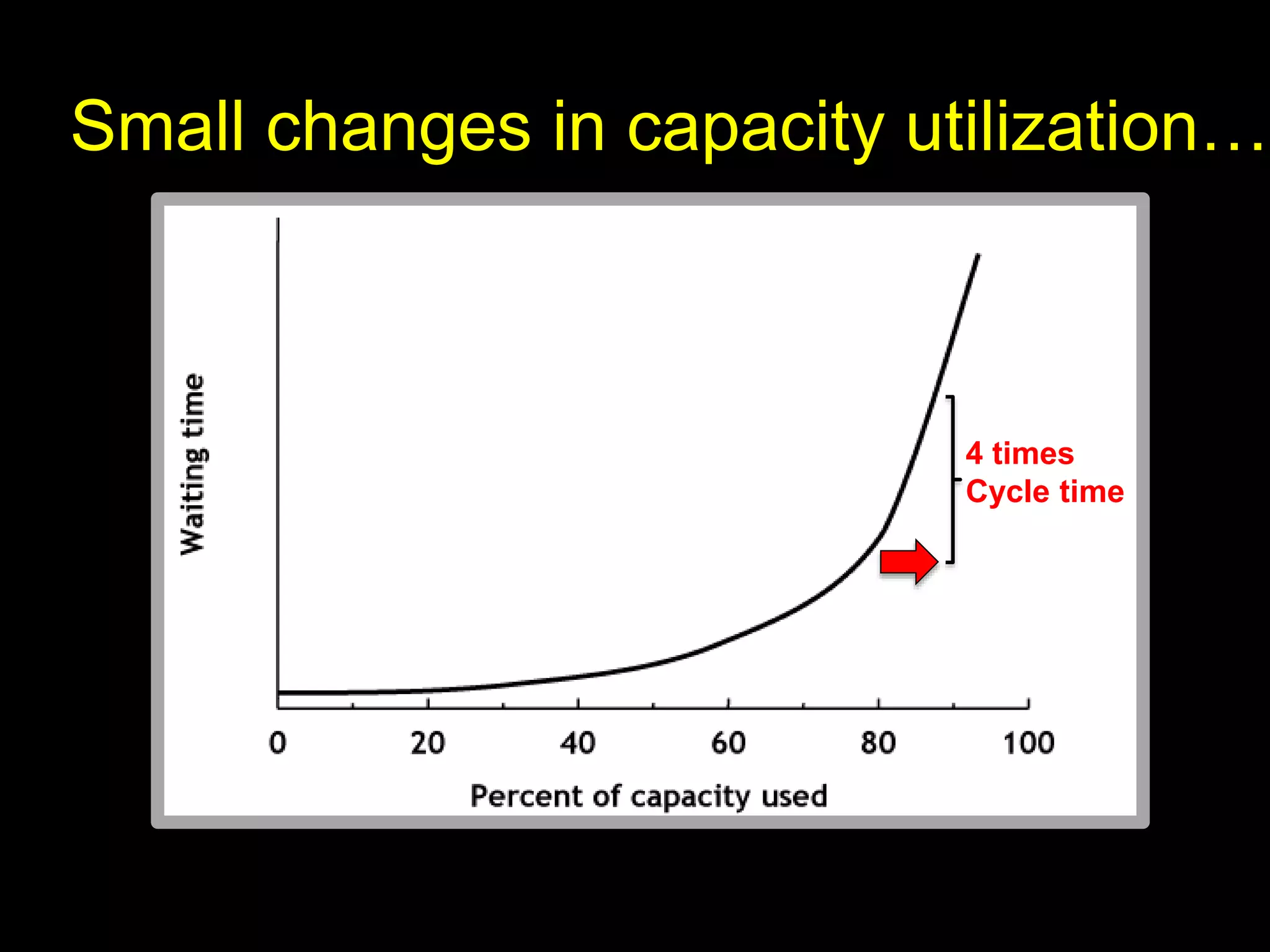

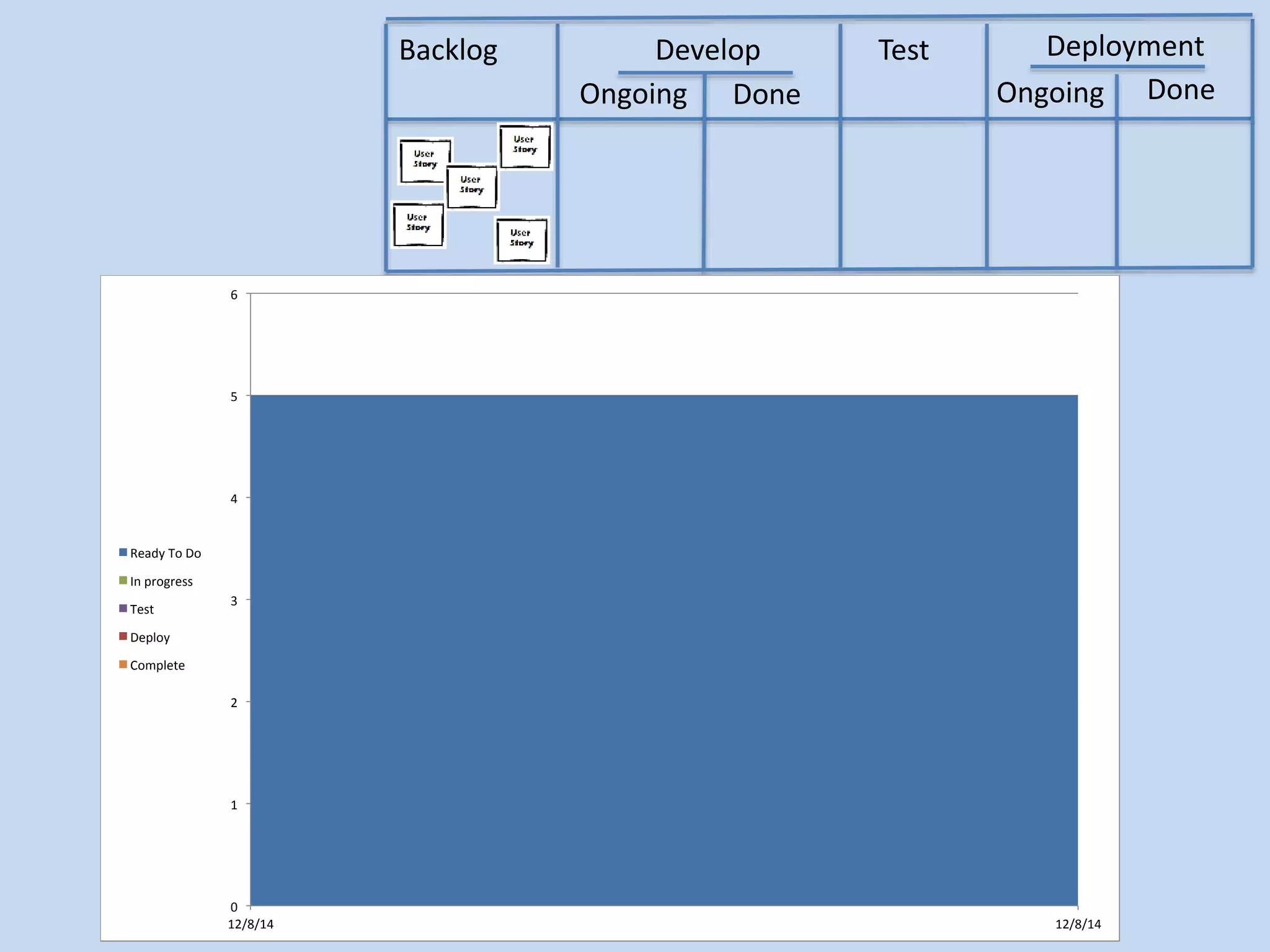

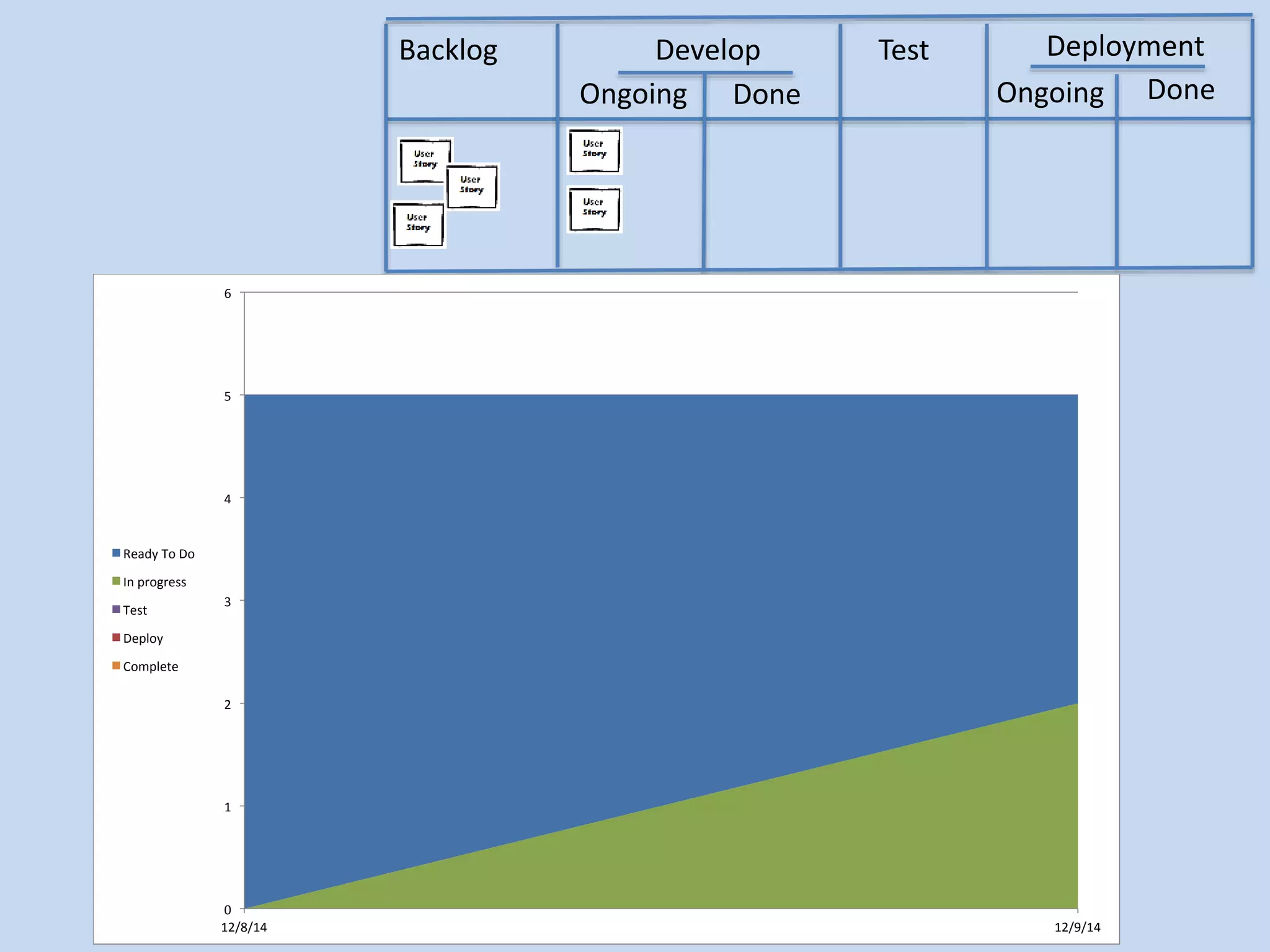

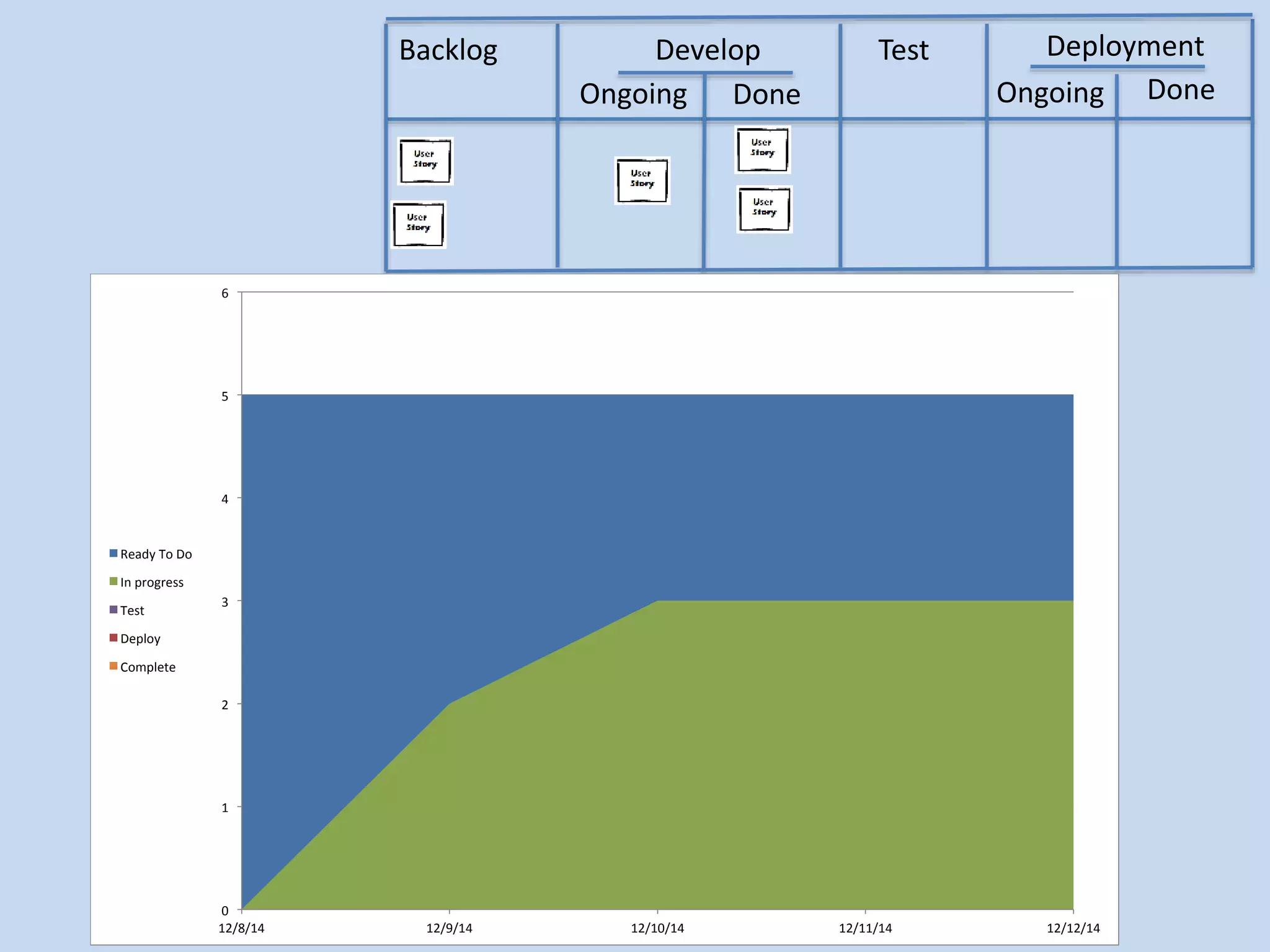

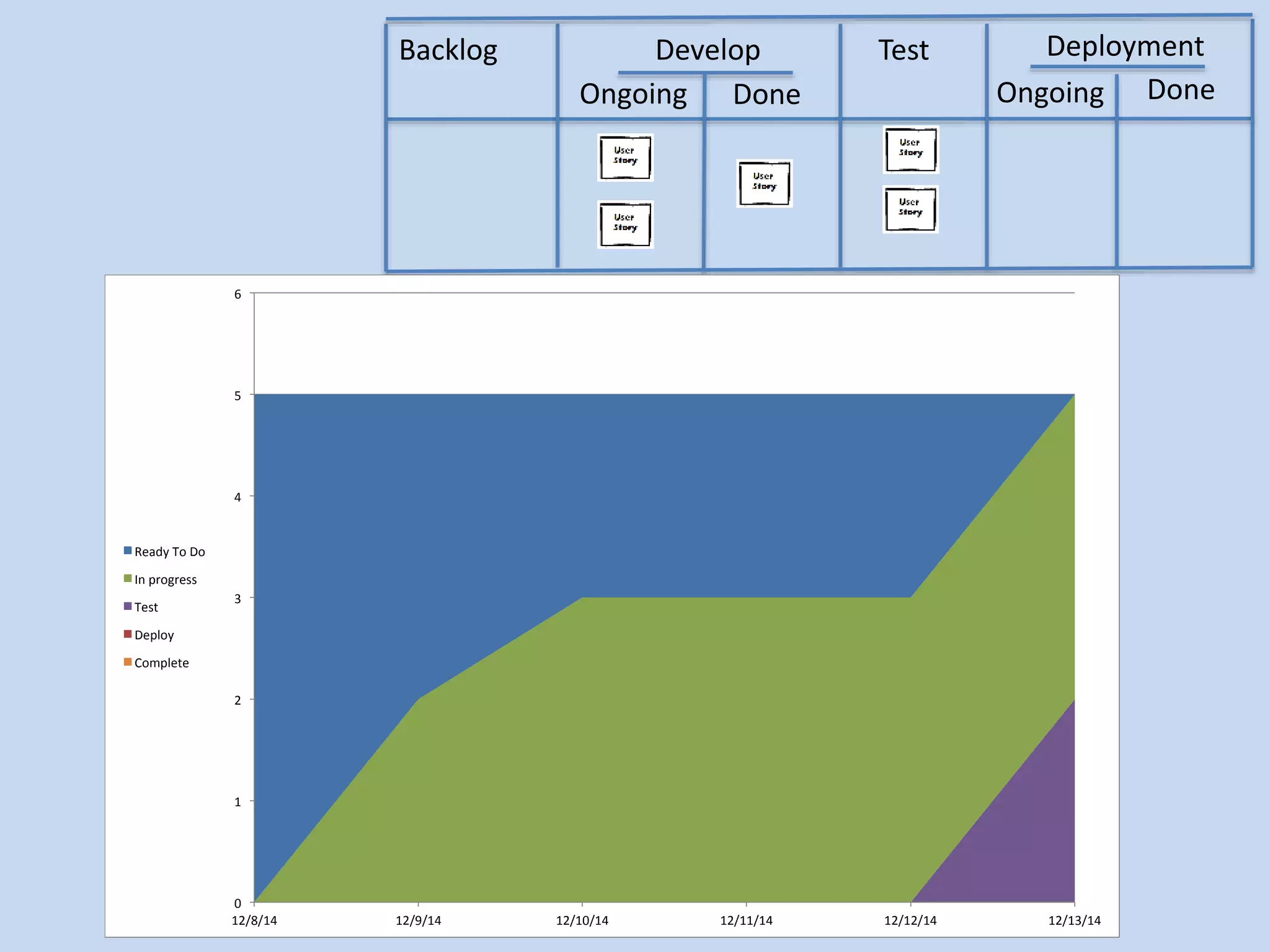

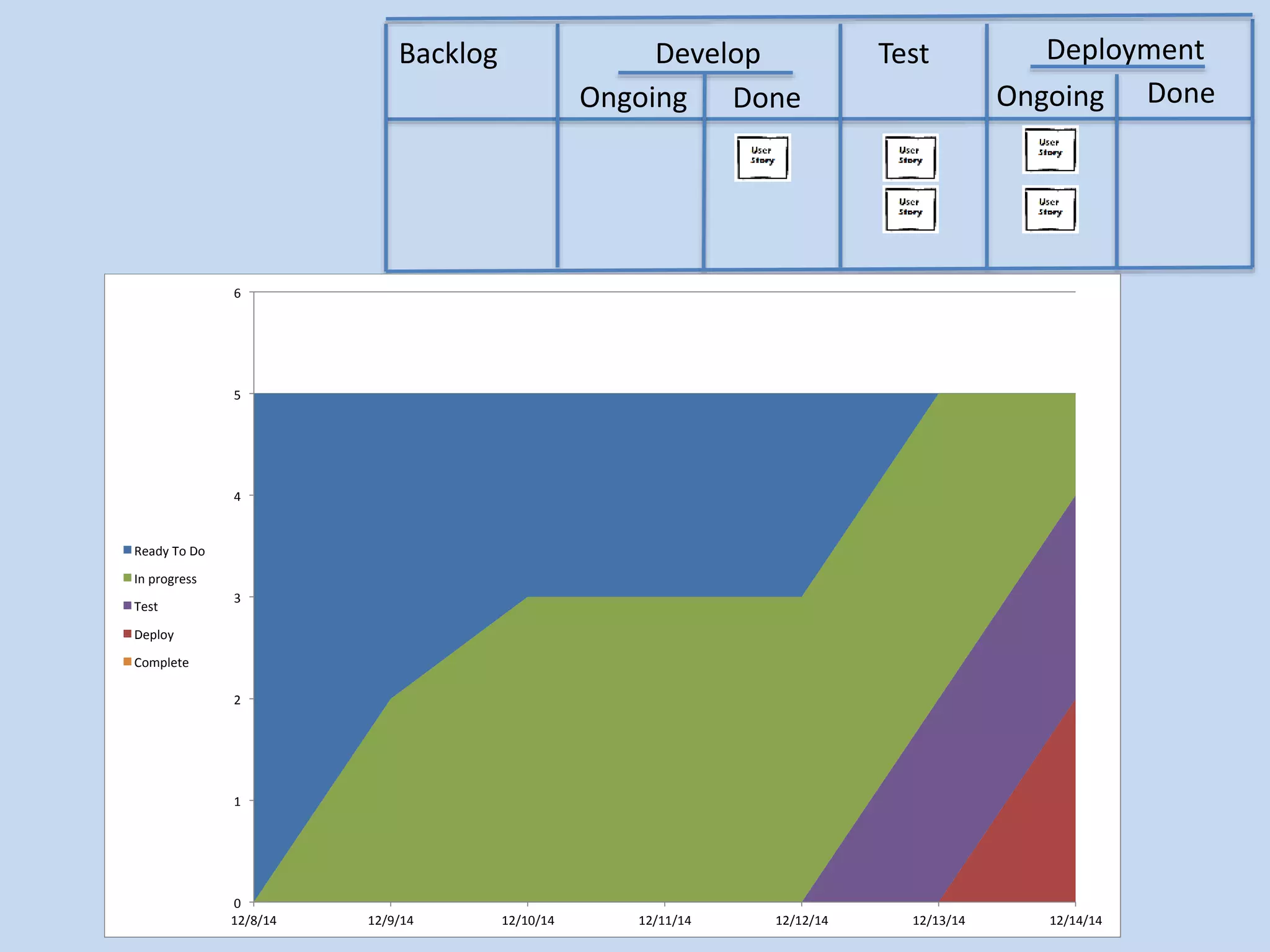

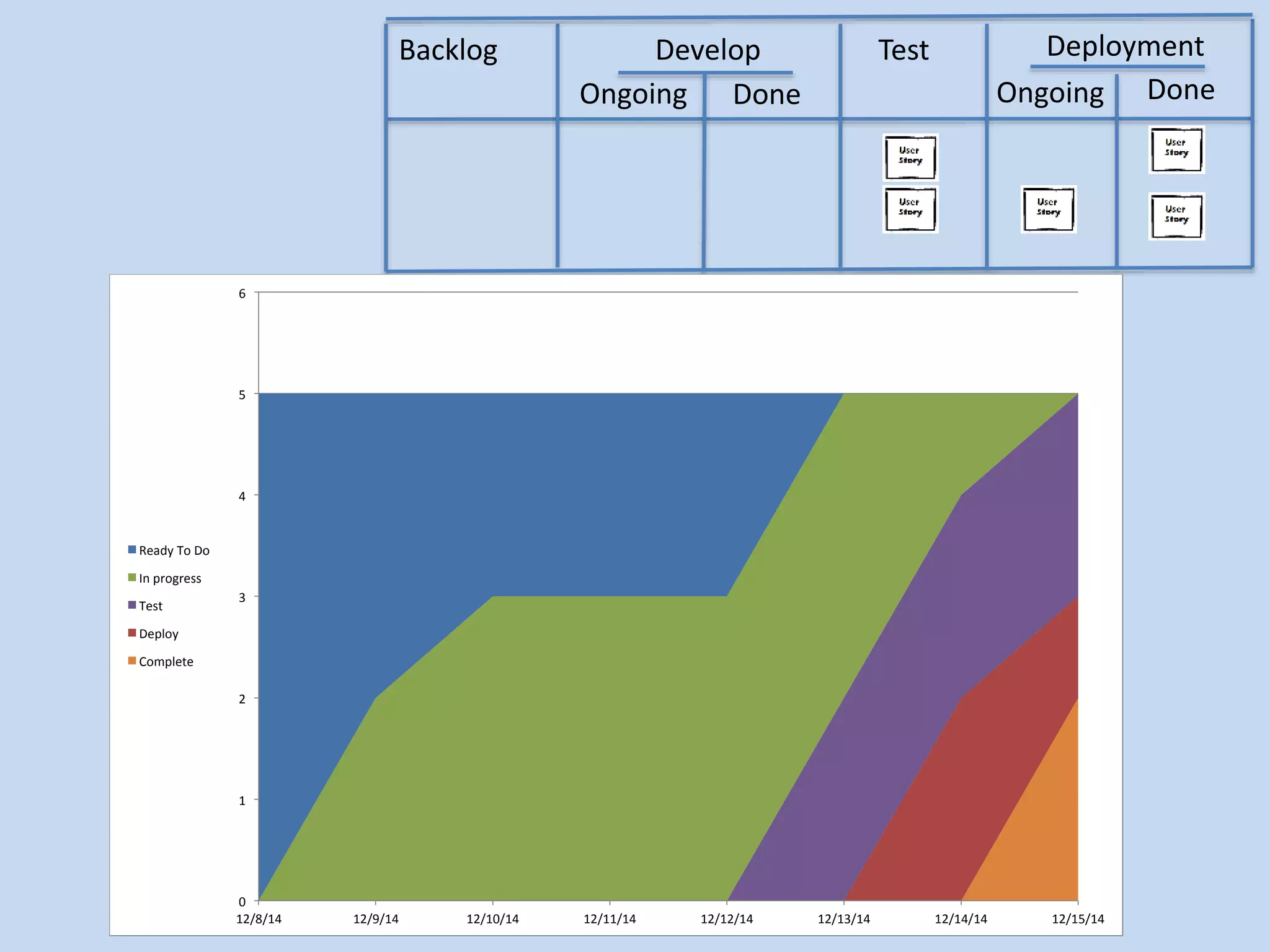

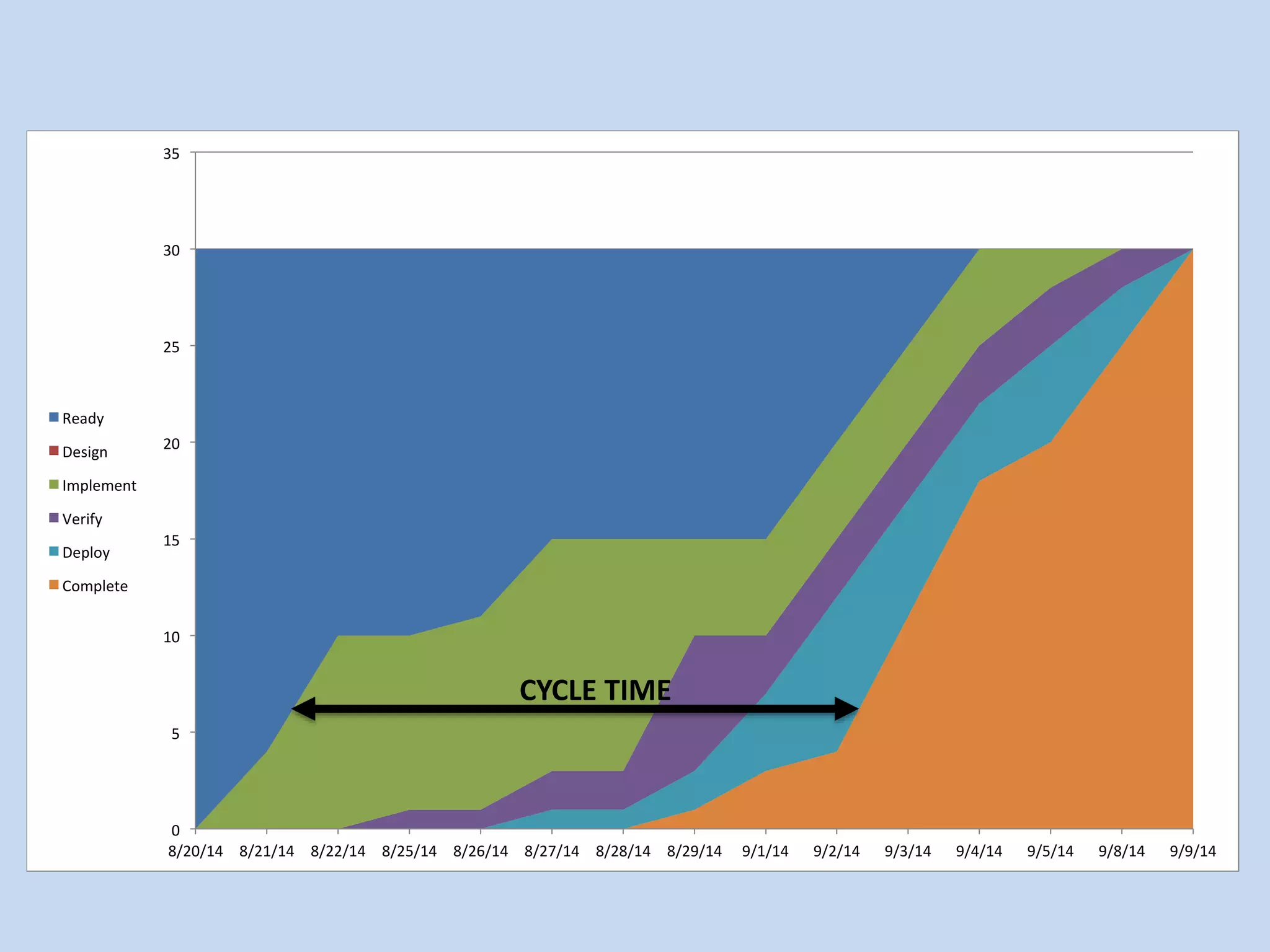

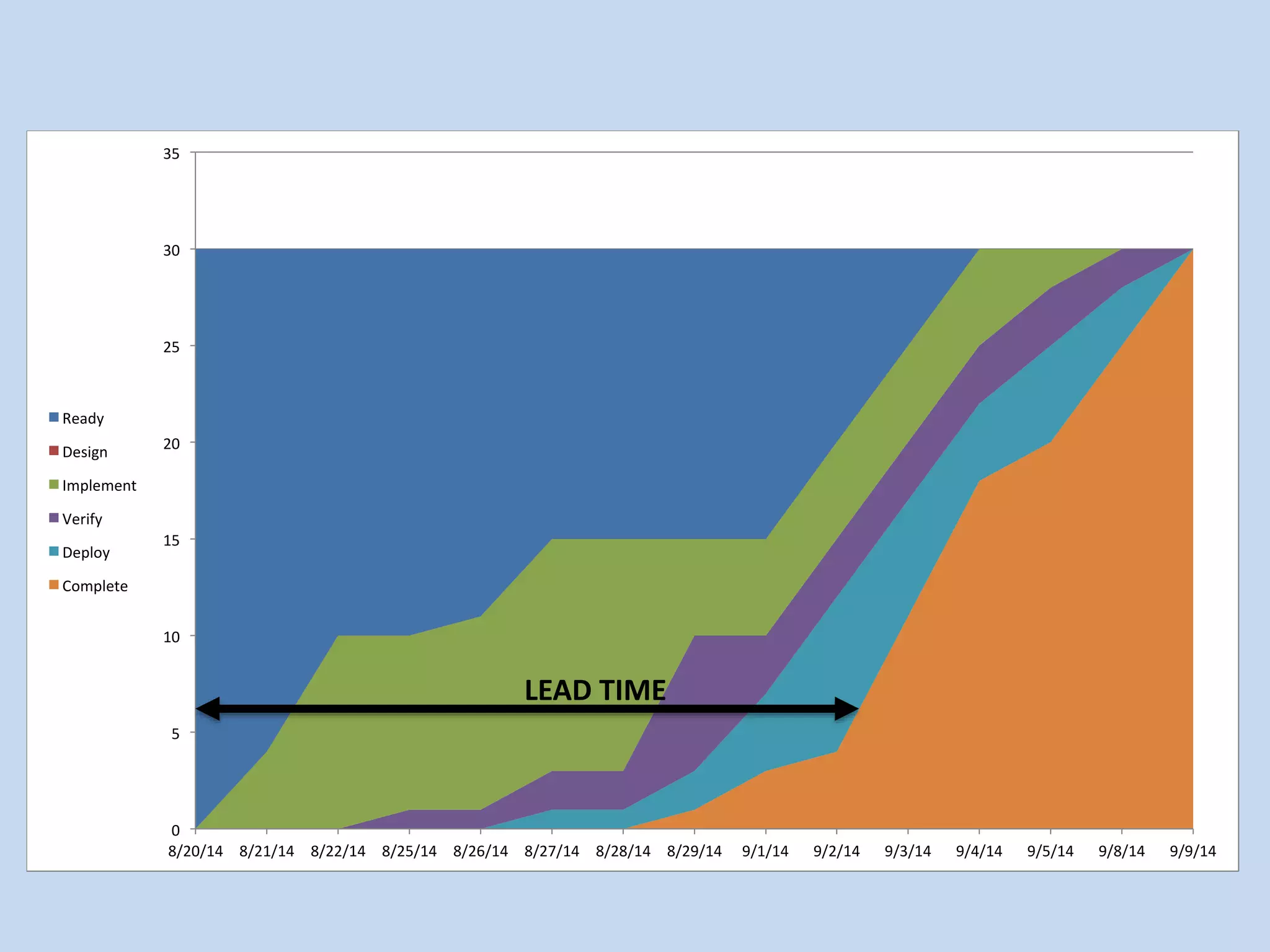

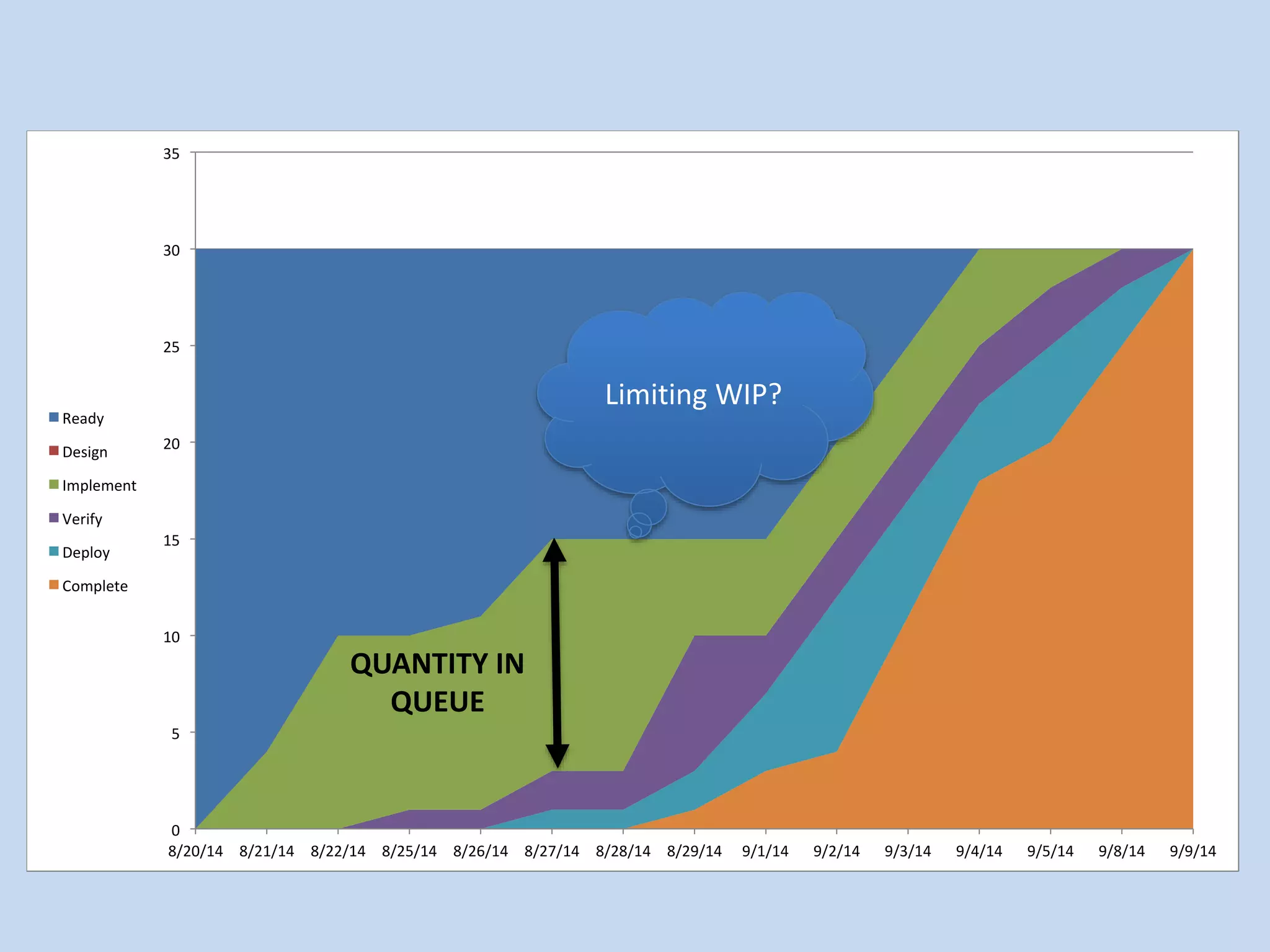

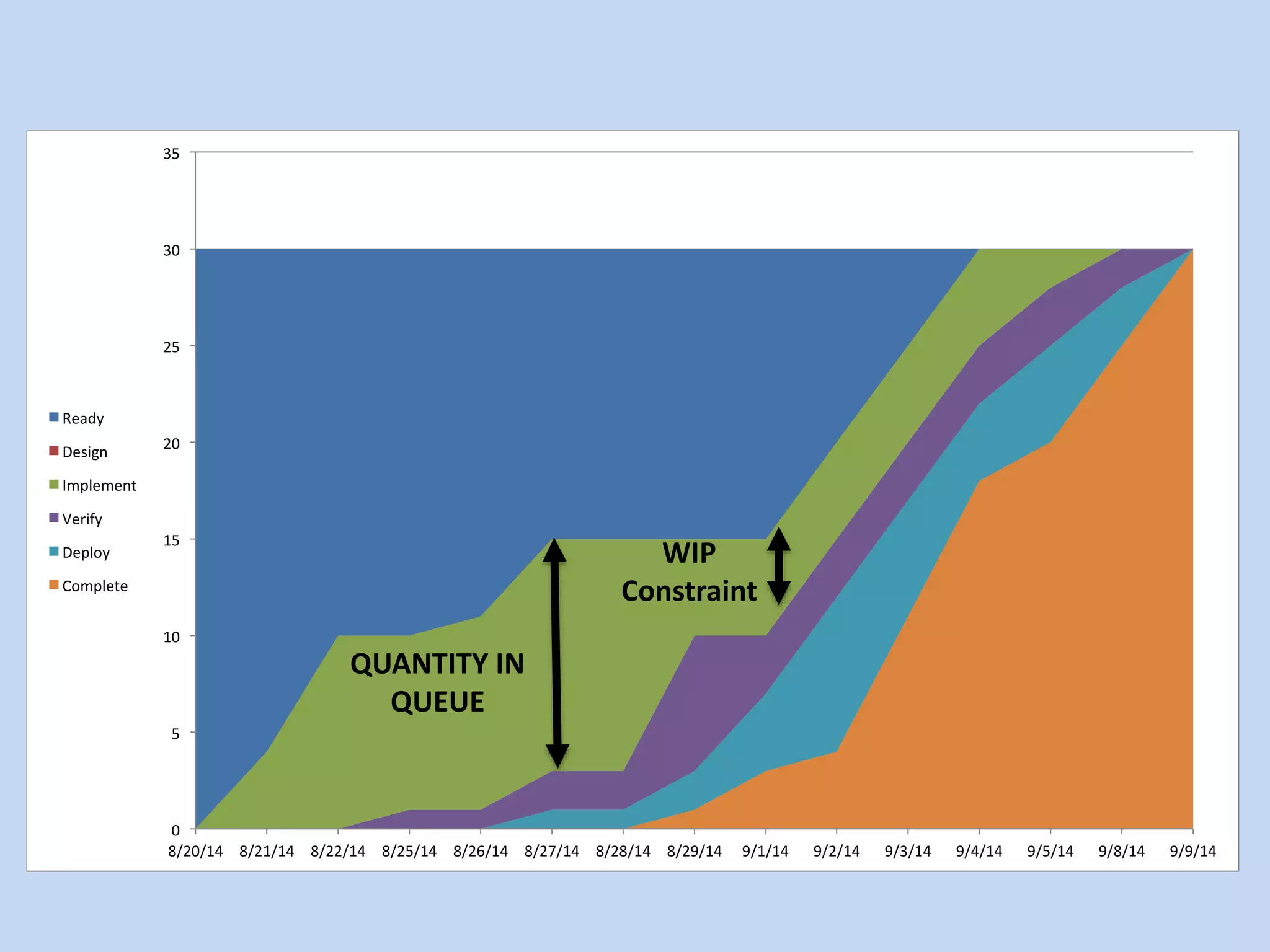

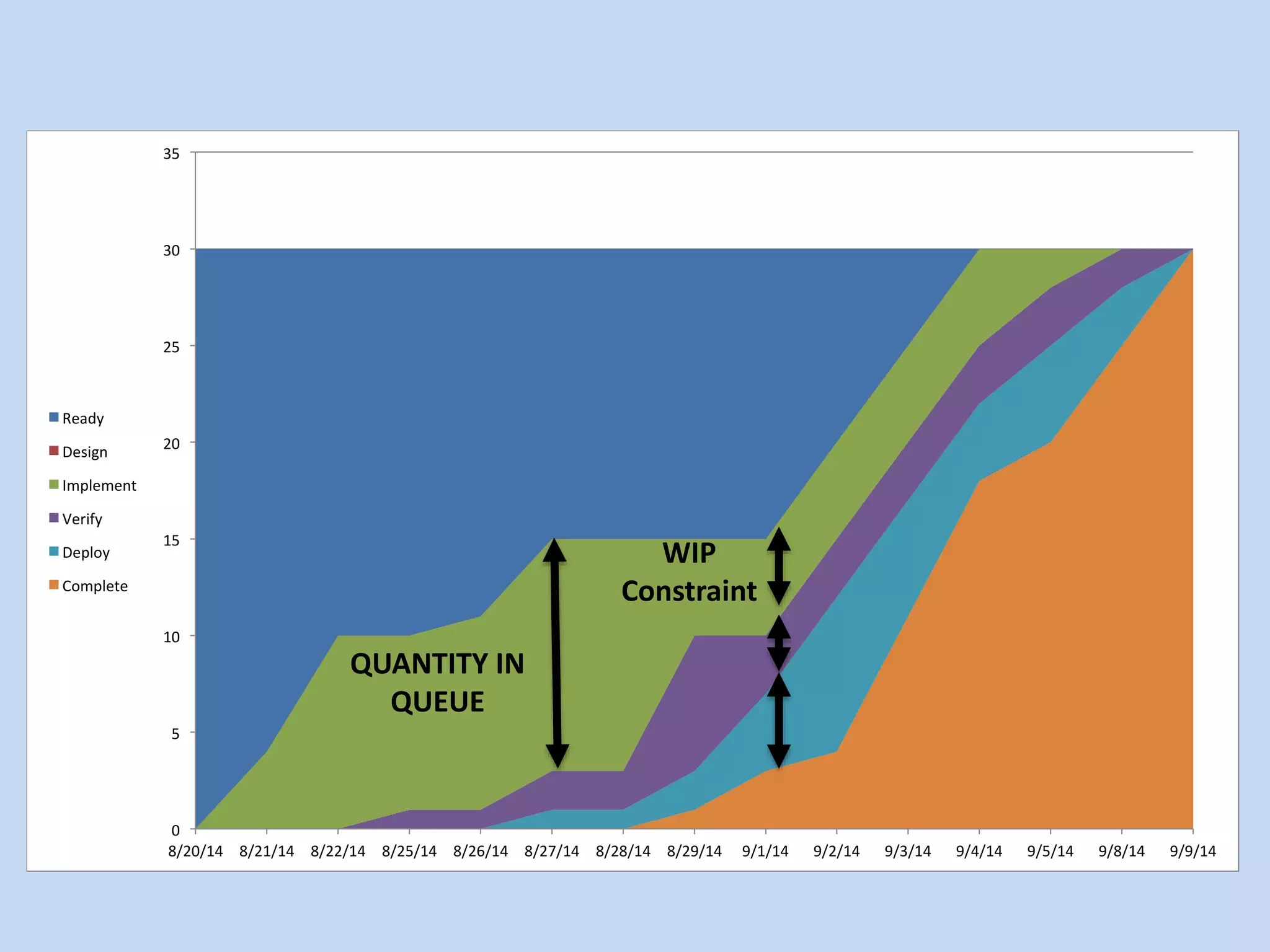

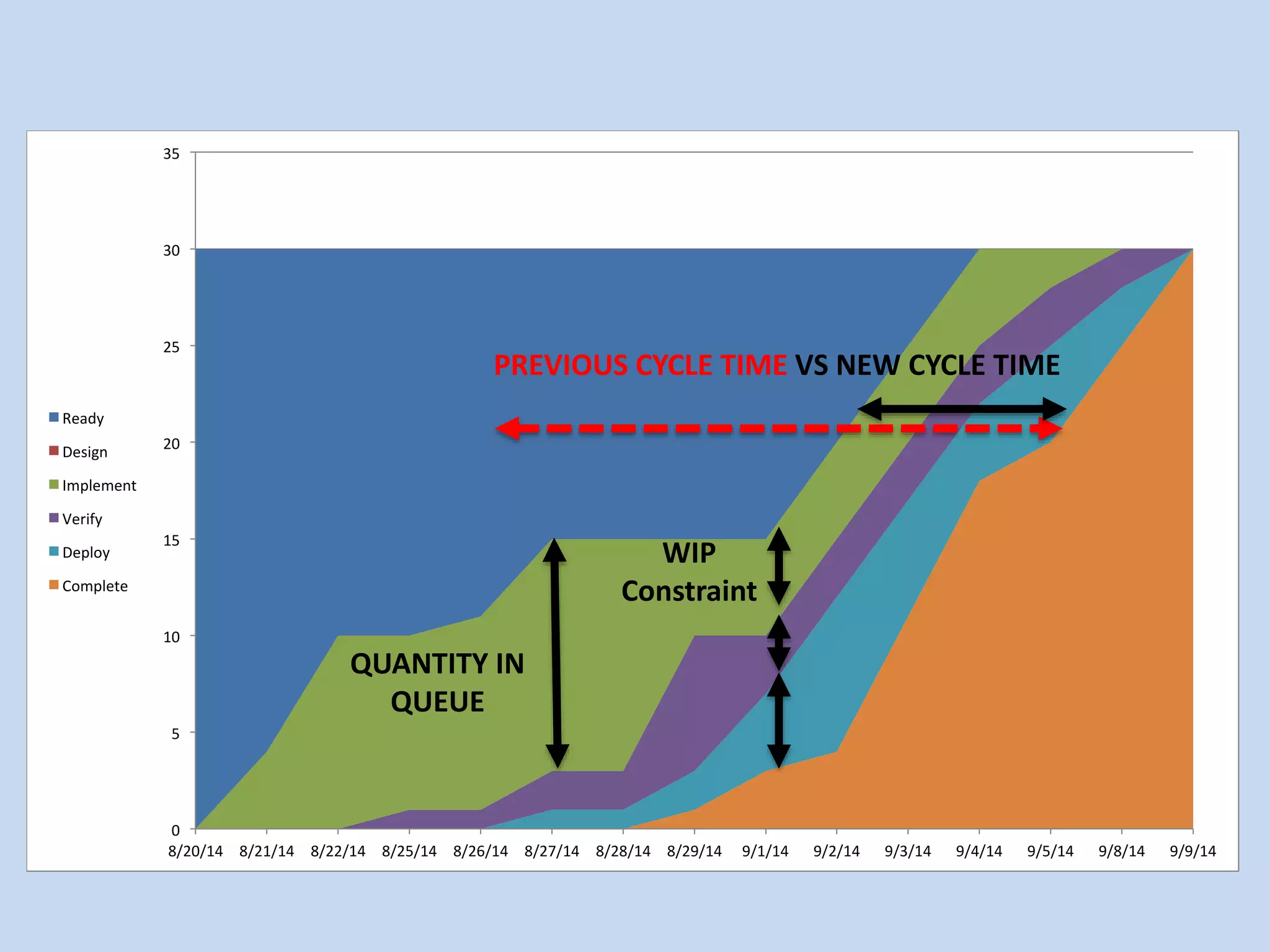

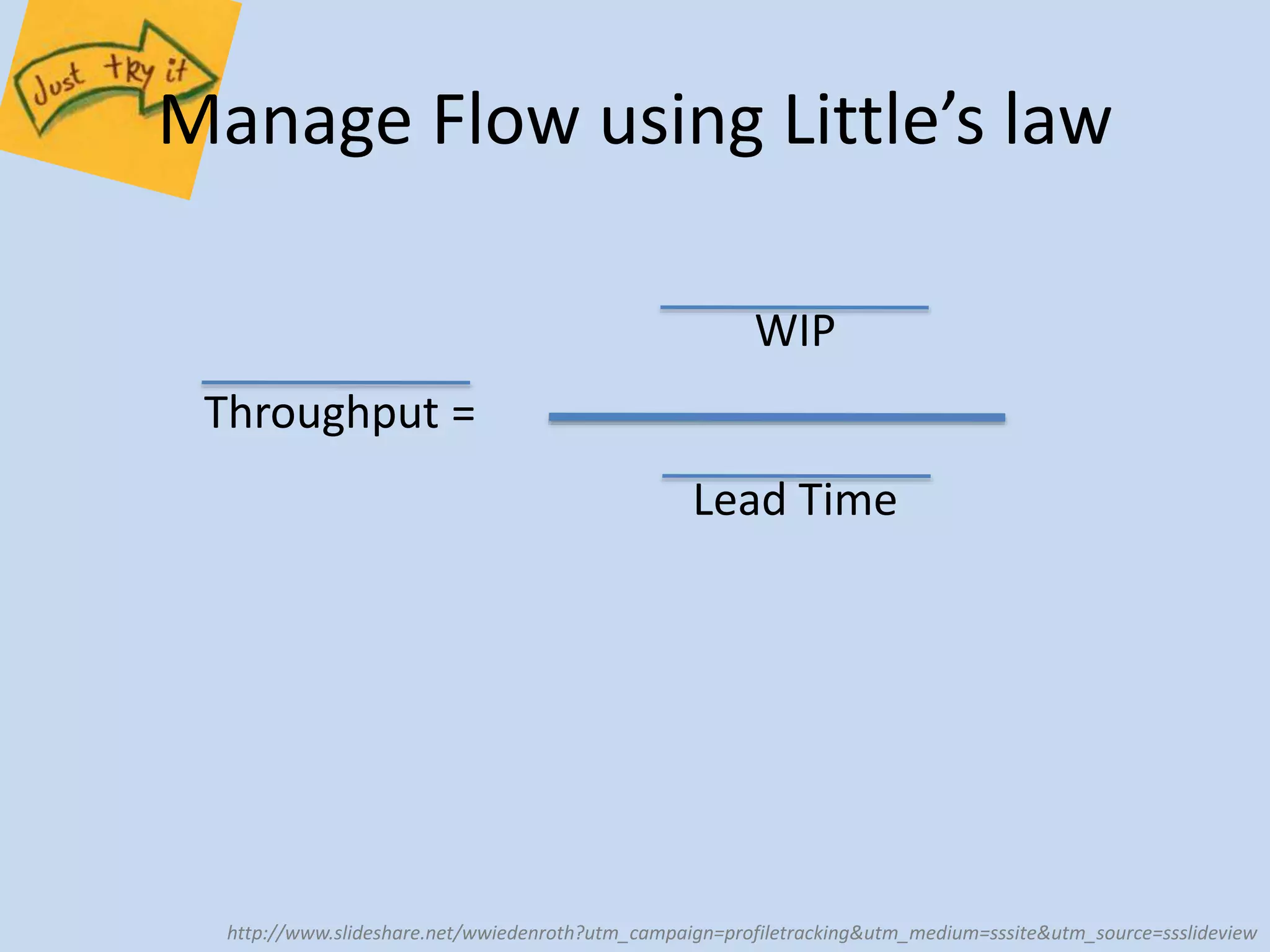

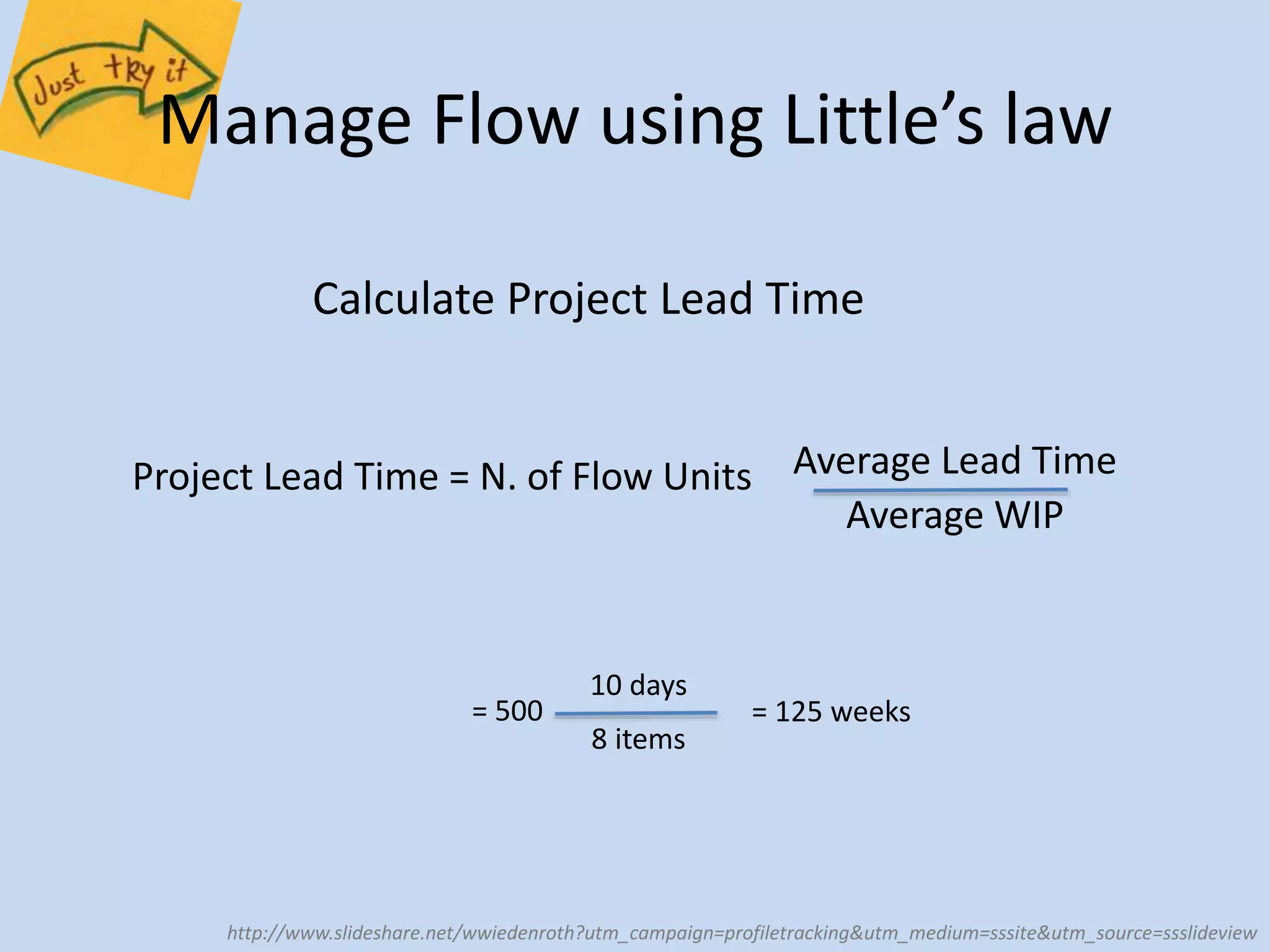

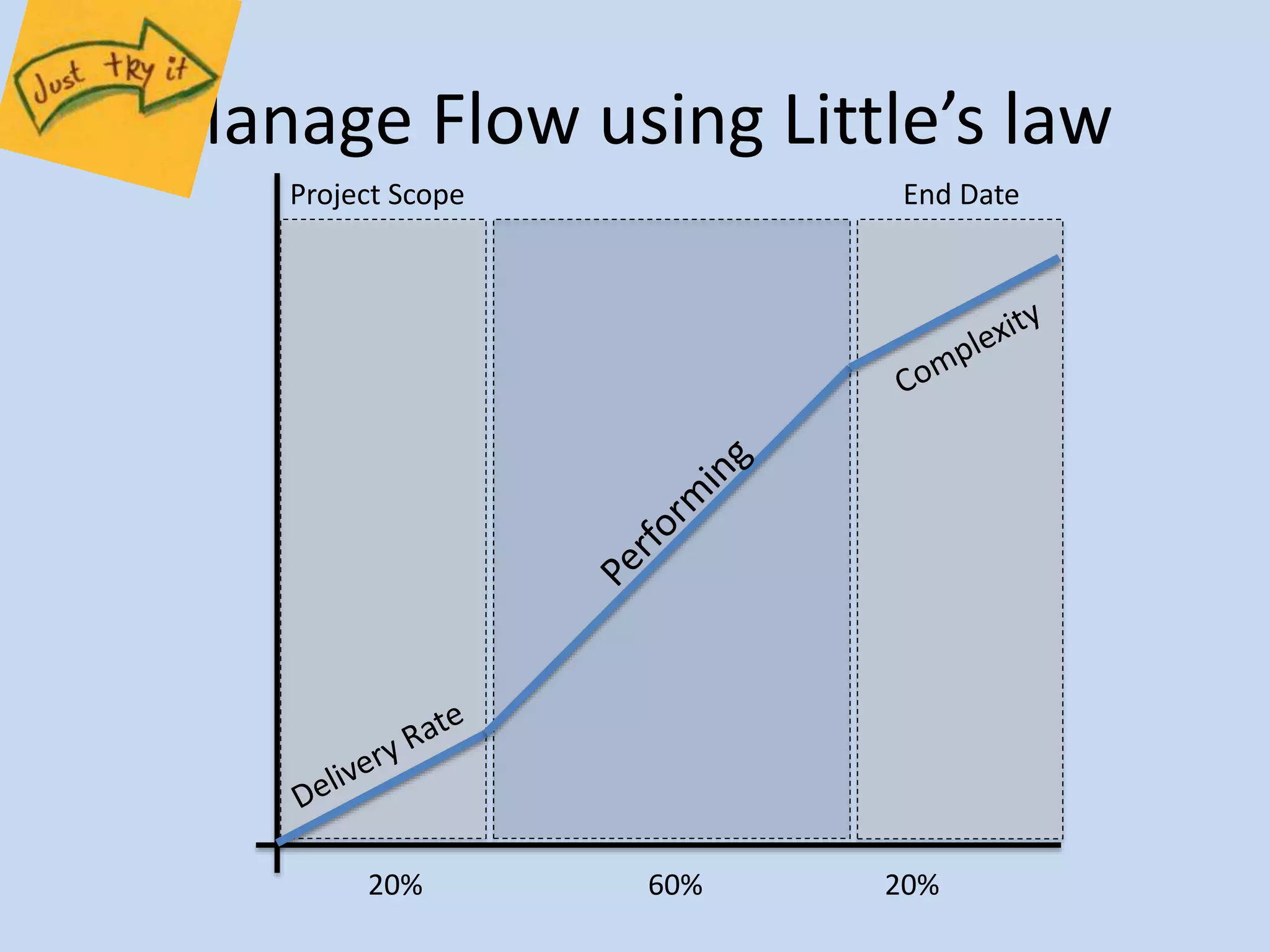

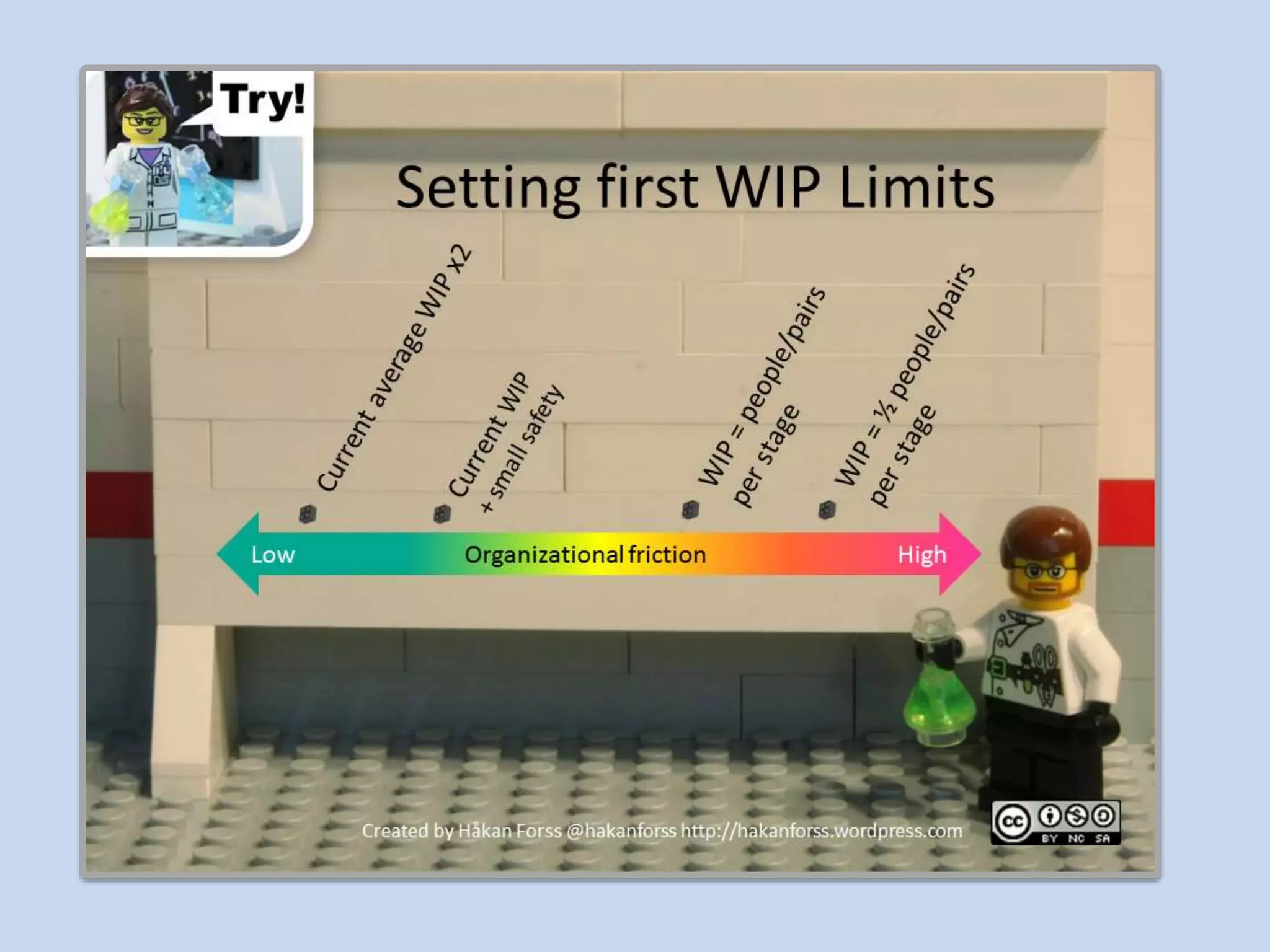

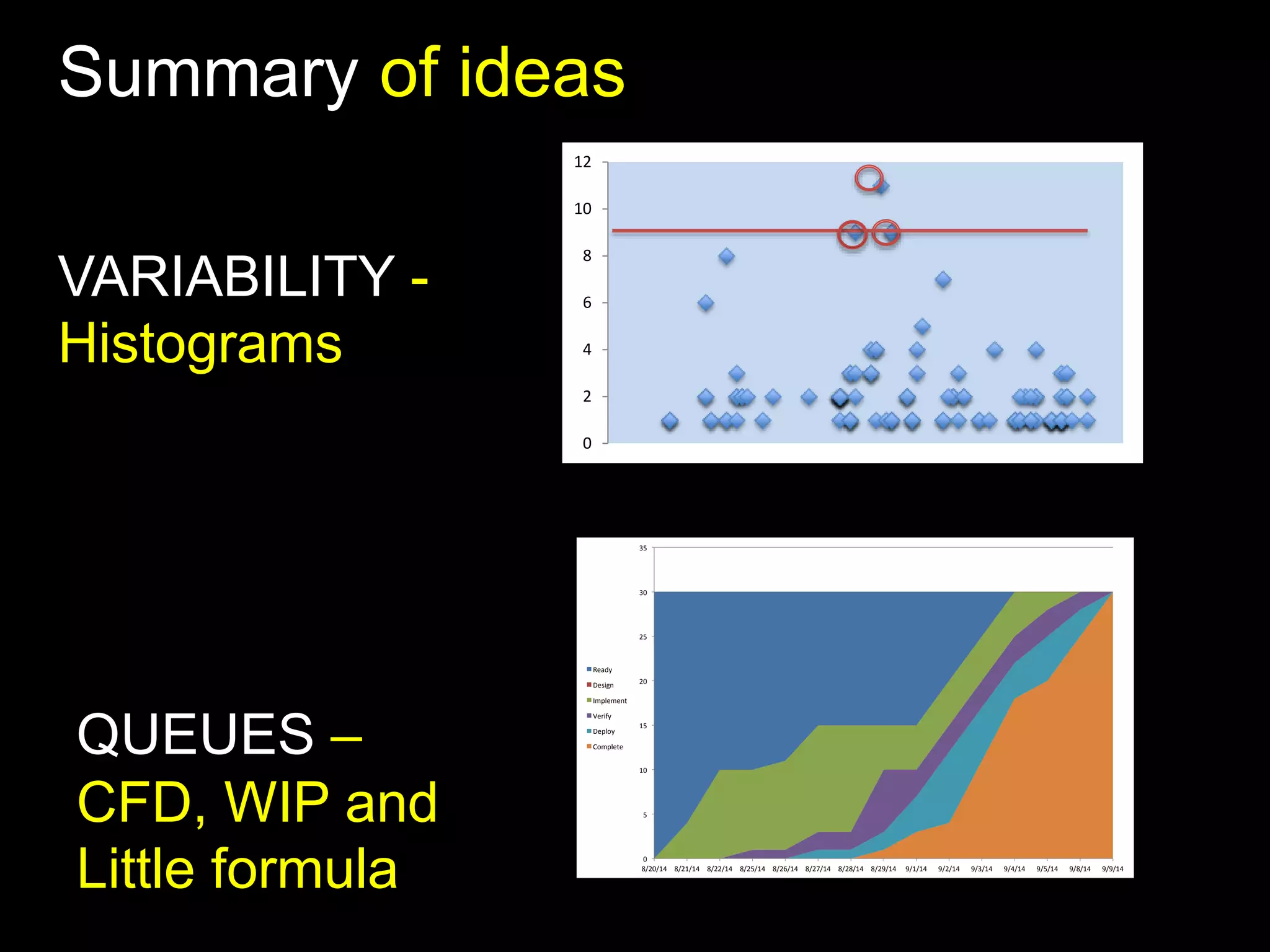

This document discusses principles and techniques for flow product development. It discusses delivering fast by focusing on flow units and eliminating non-value added activities. It emphasizes eliminating variability where possible, but introducing variability where it adds value. Tools discussed for managing flow include using histograms to understand variability in cycle times, cumulative flow diagrams to visualize work in progress and identify bottlenecks, and Little's law to calculate lead times and improve throughput. The goal is to continuously deliver value to customers by optimizing flow through the development process.