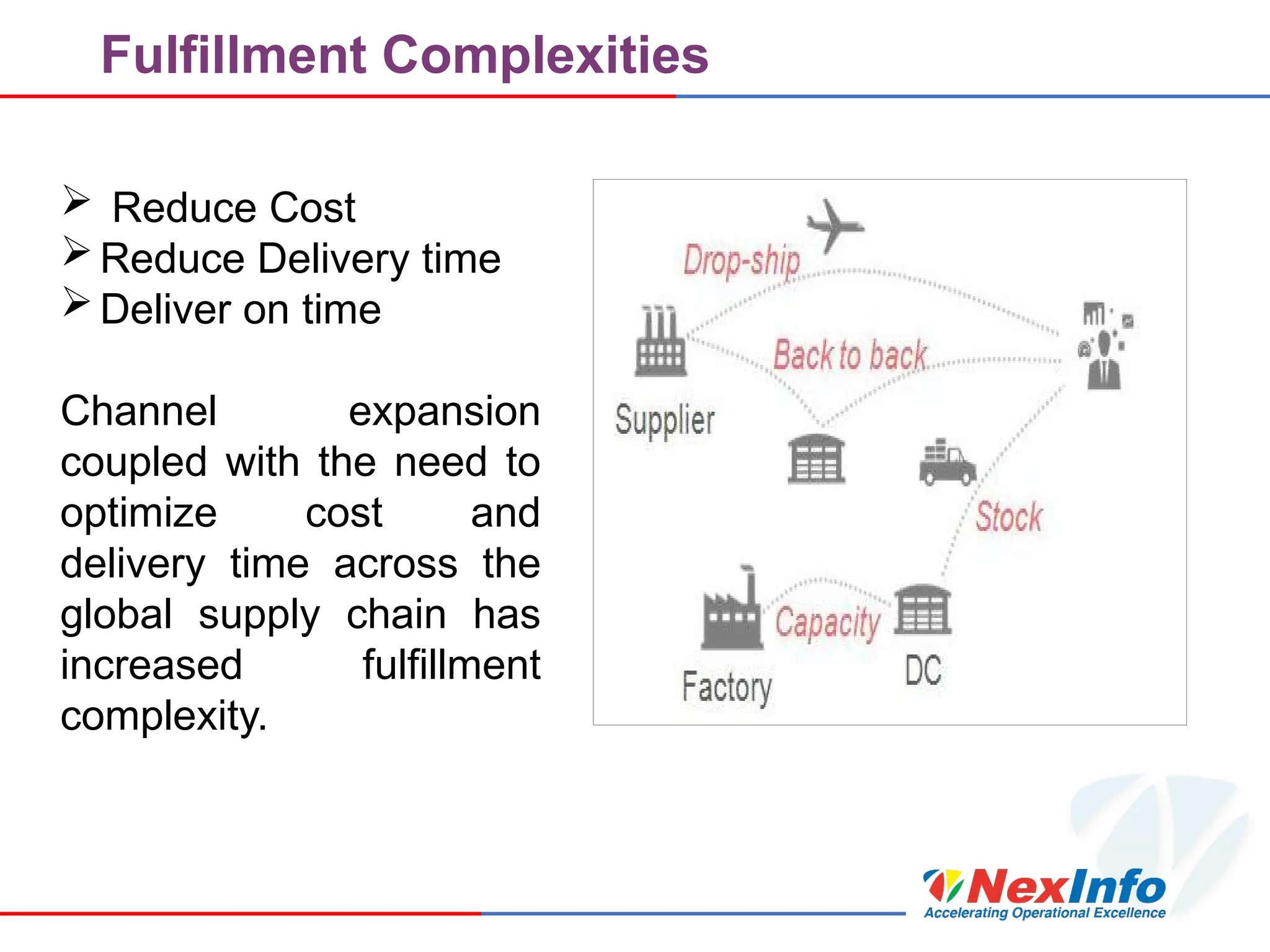

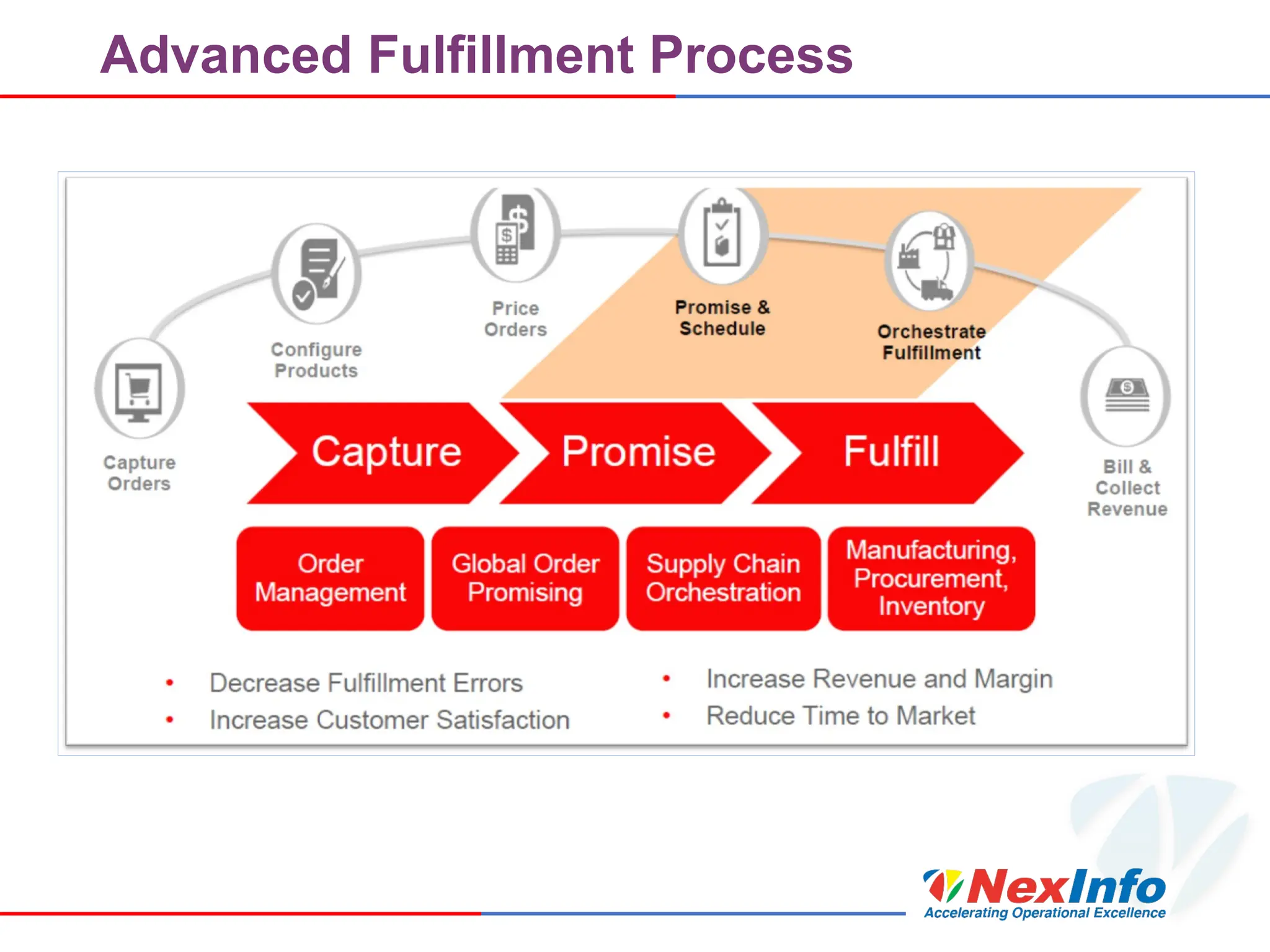

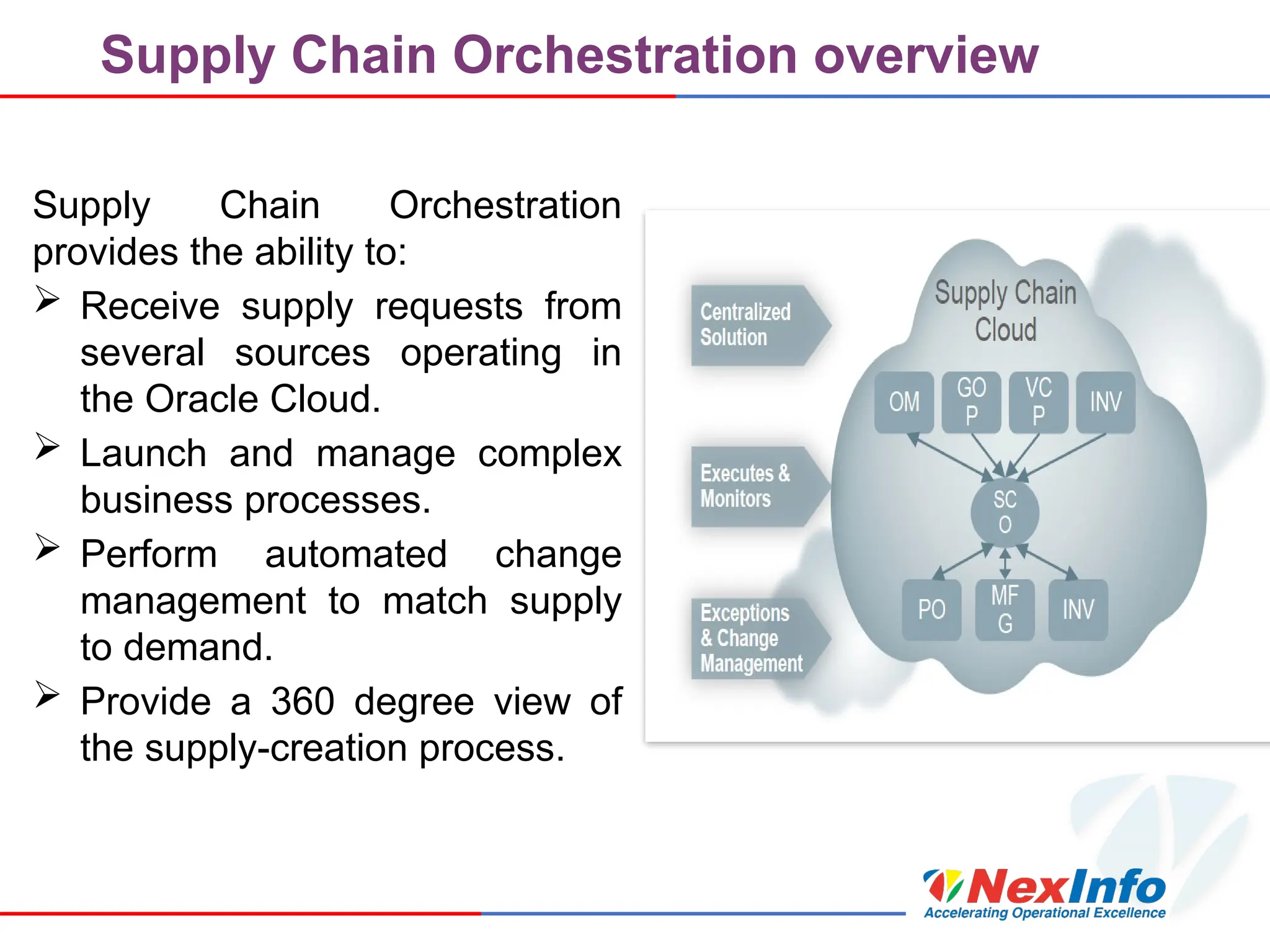

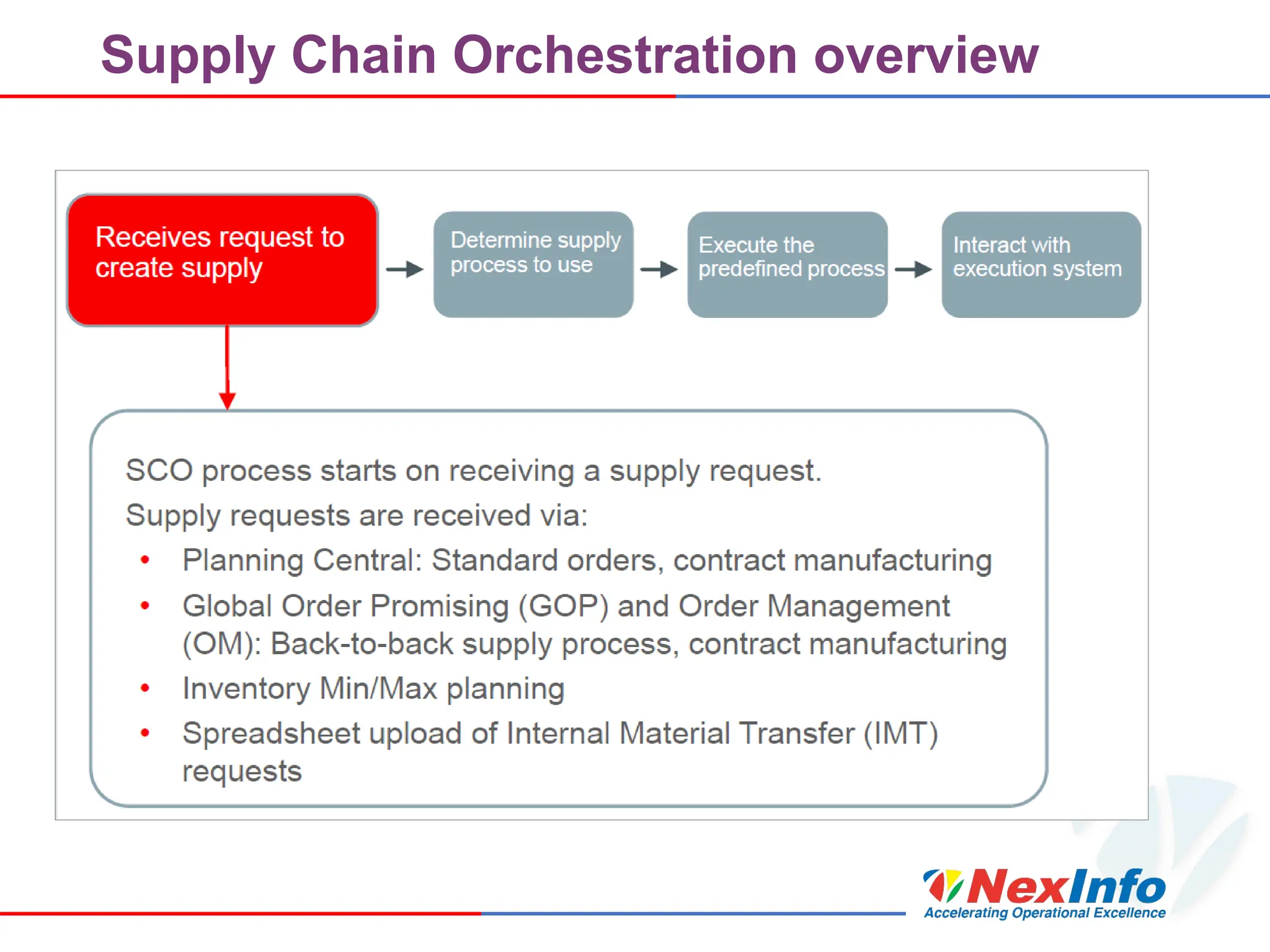

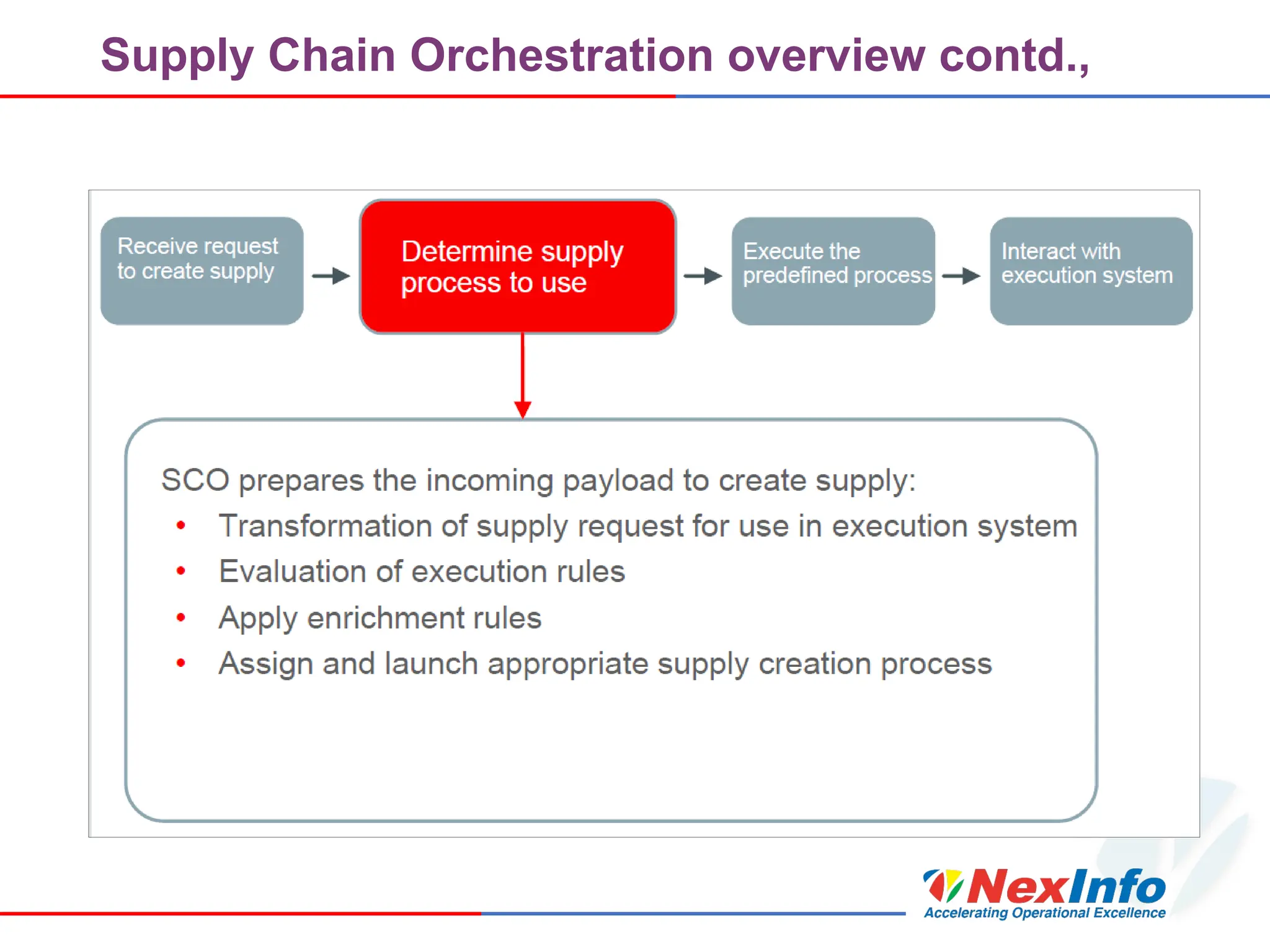

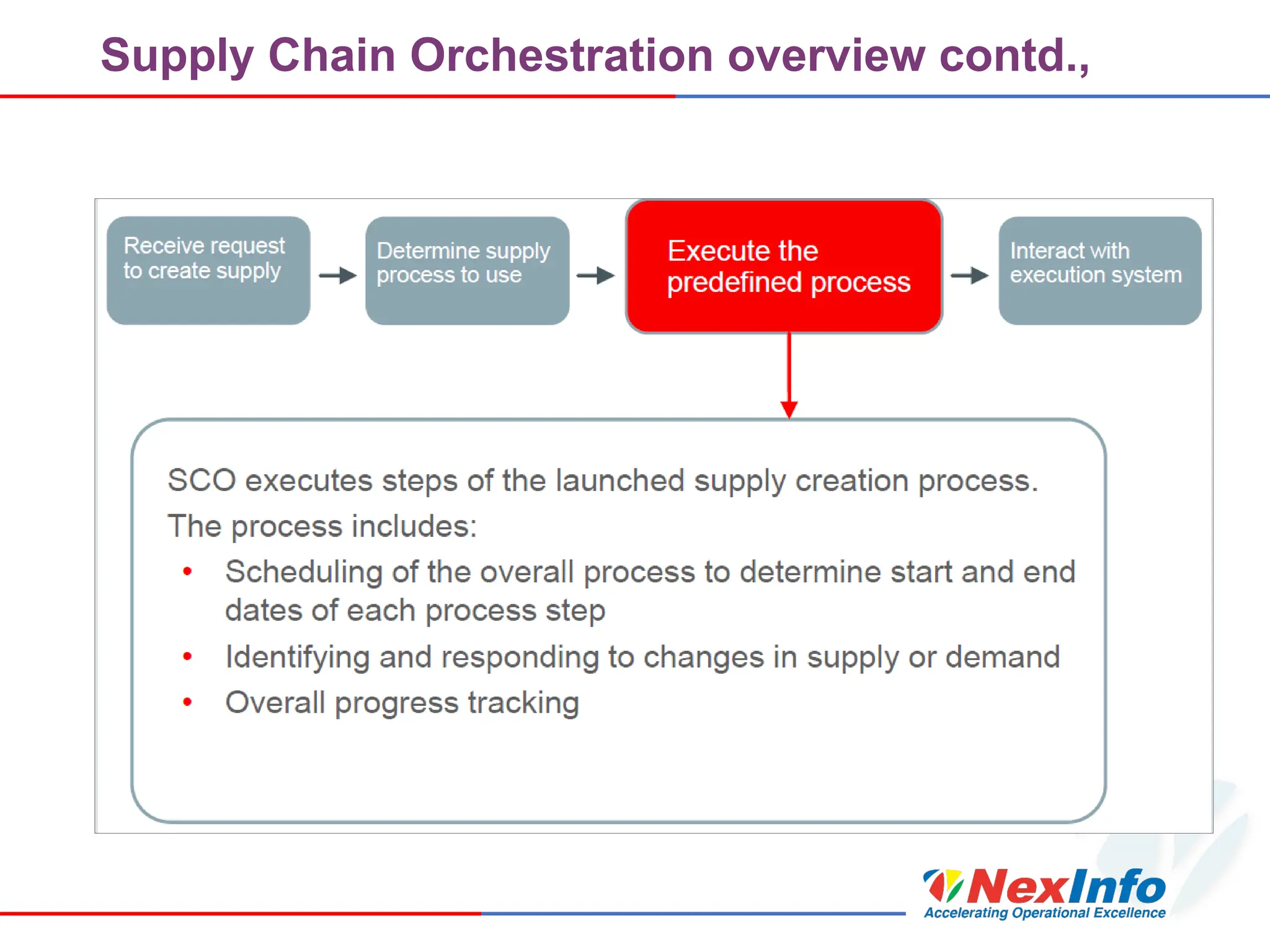

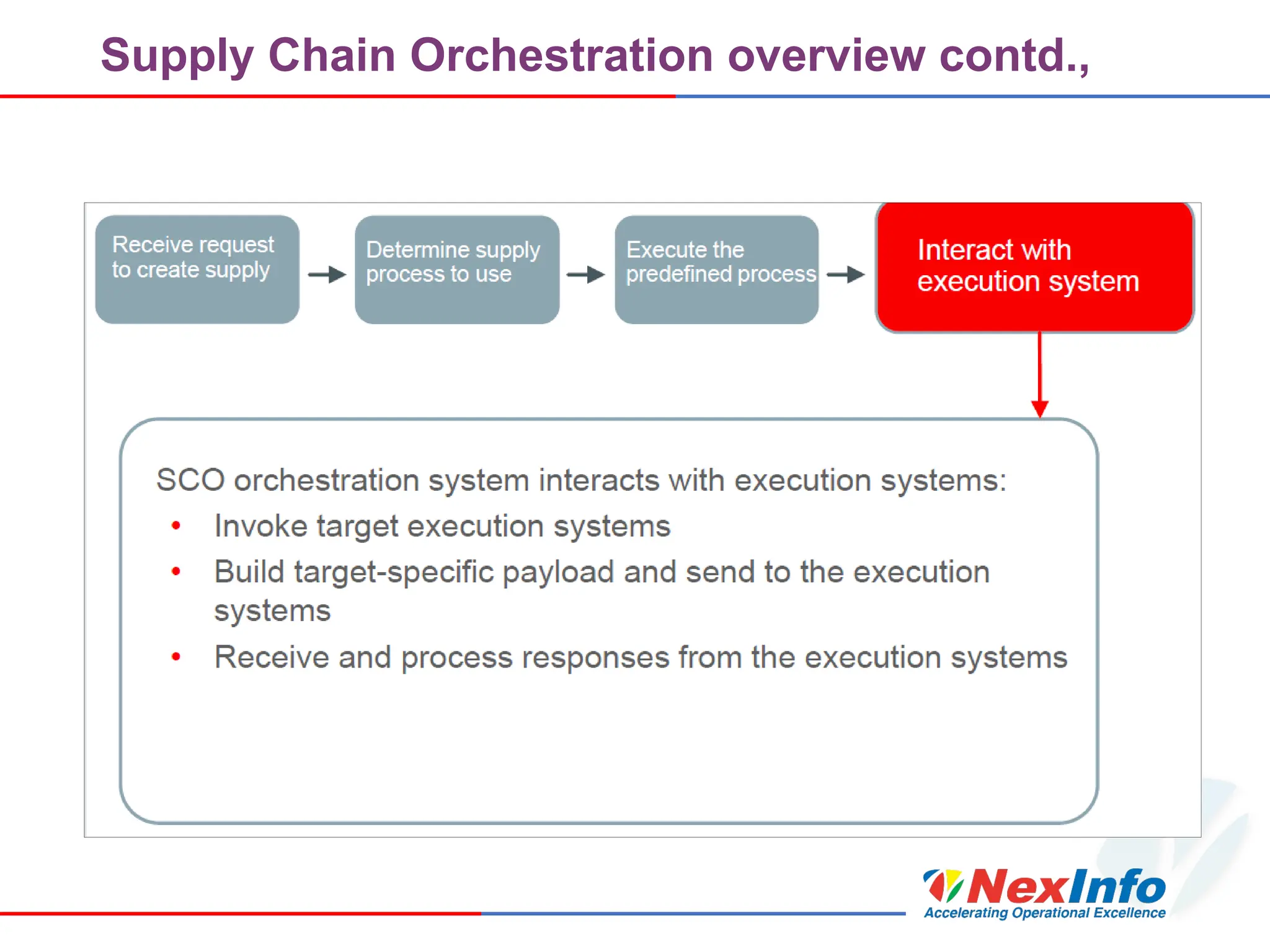

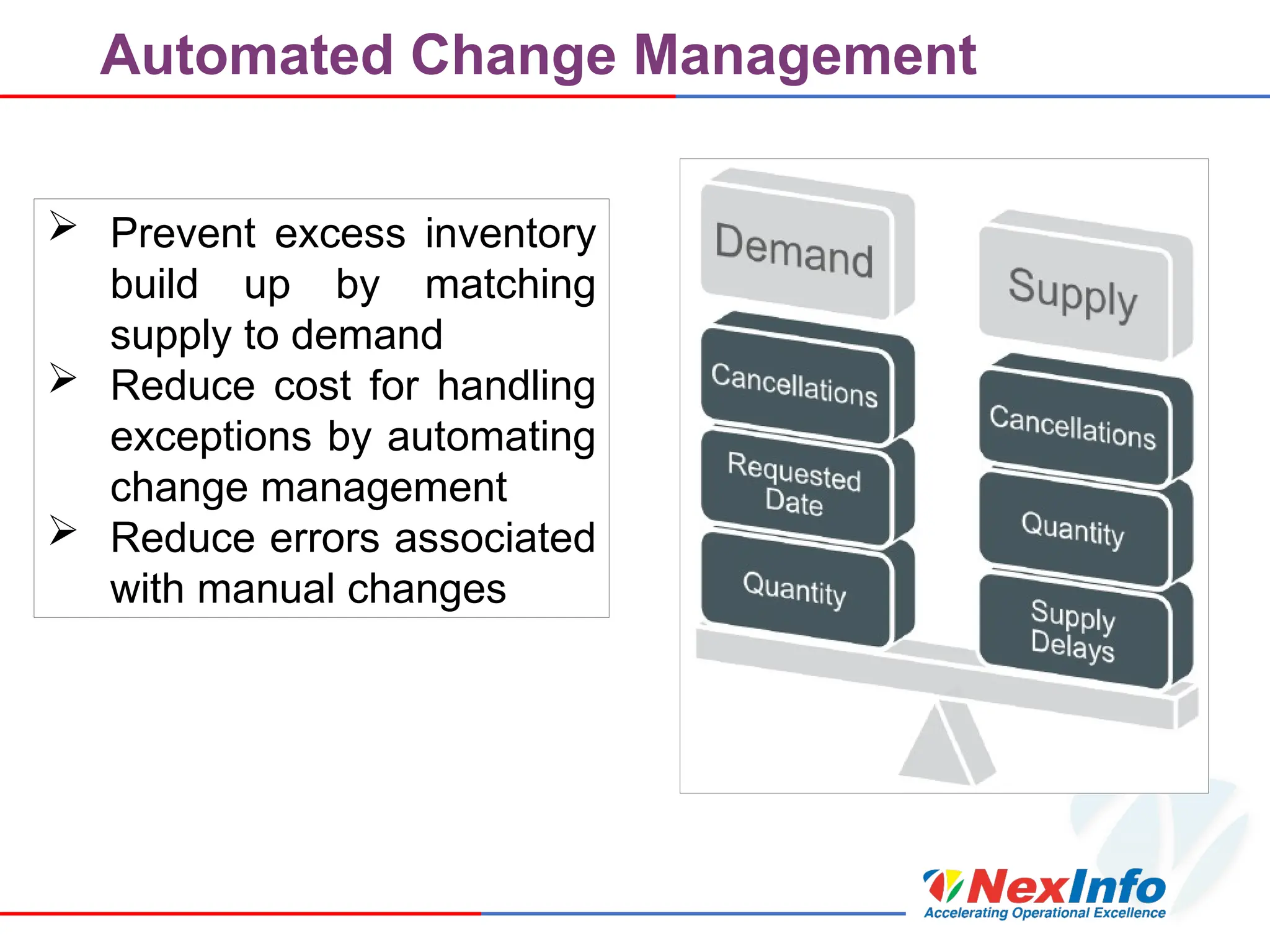

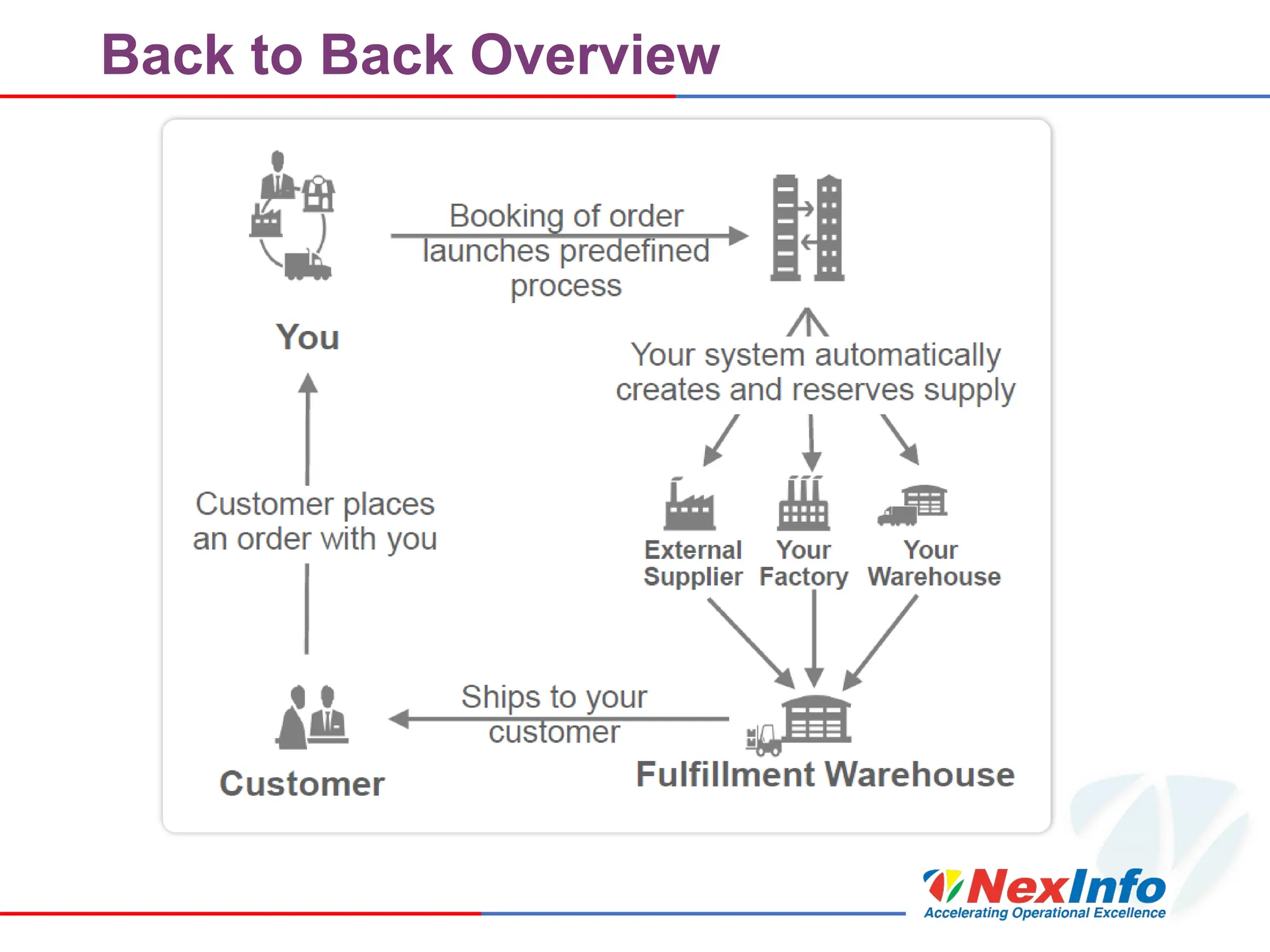

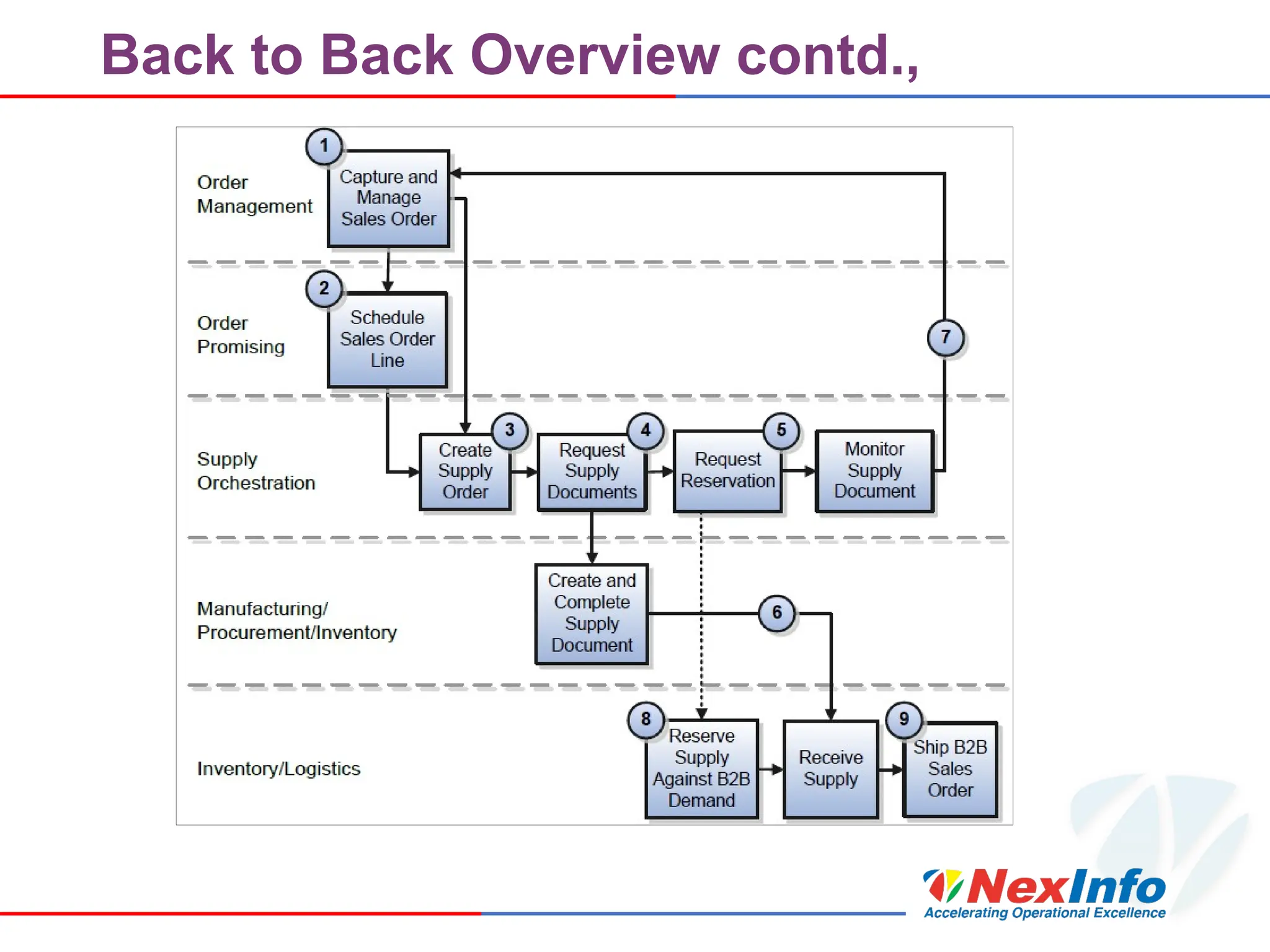

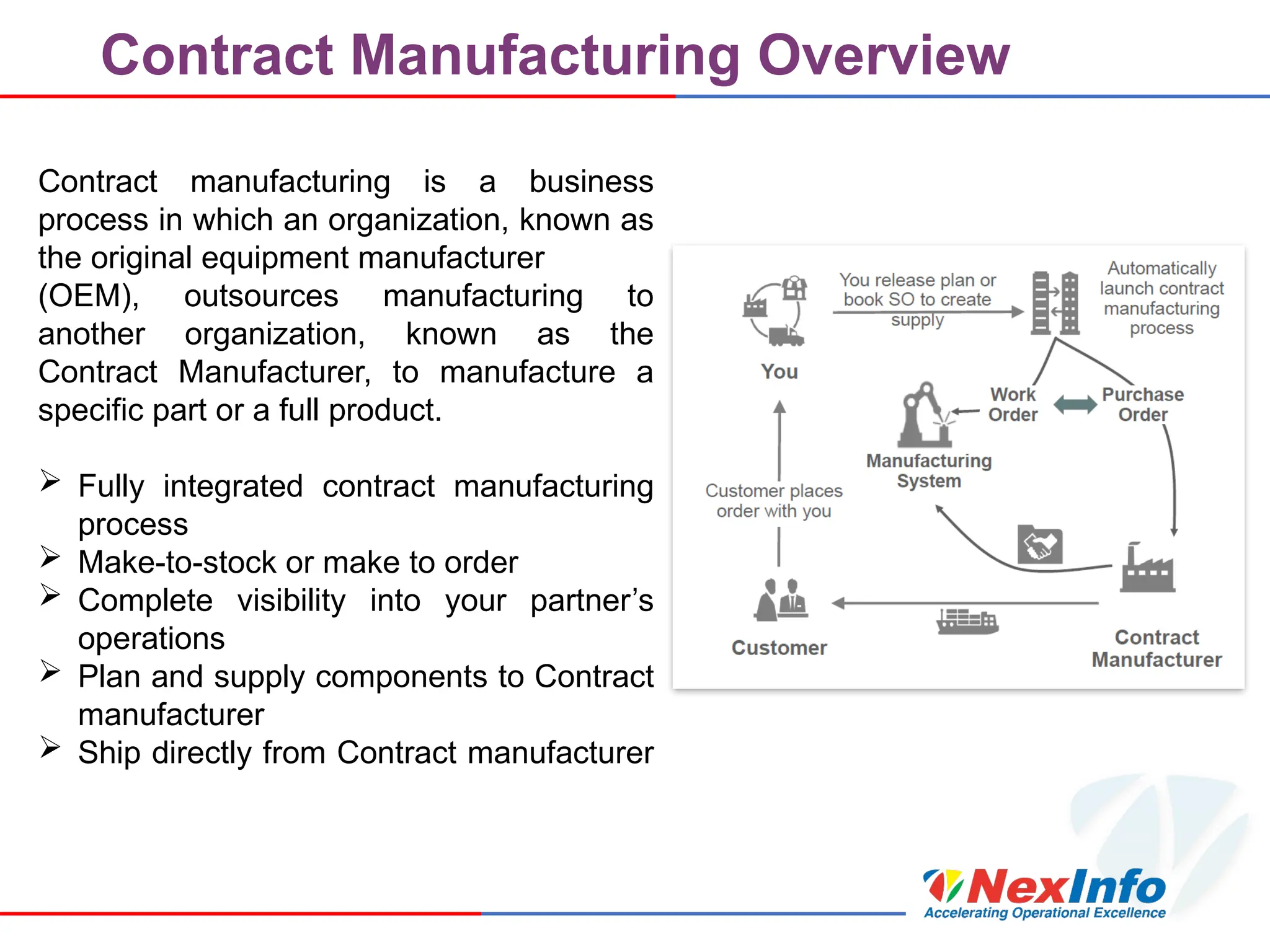

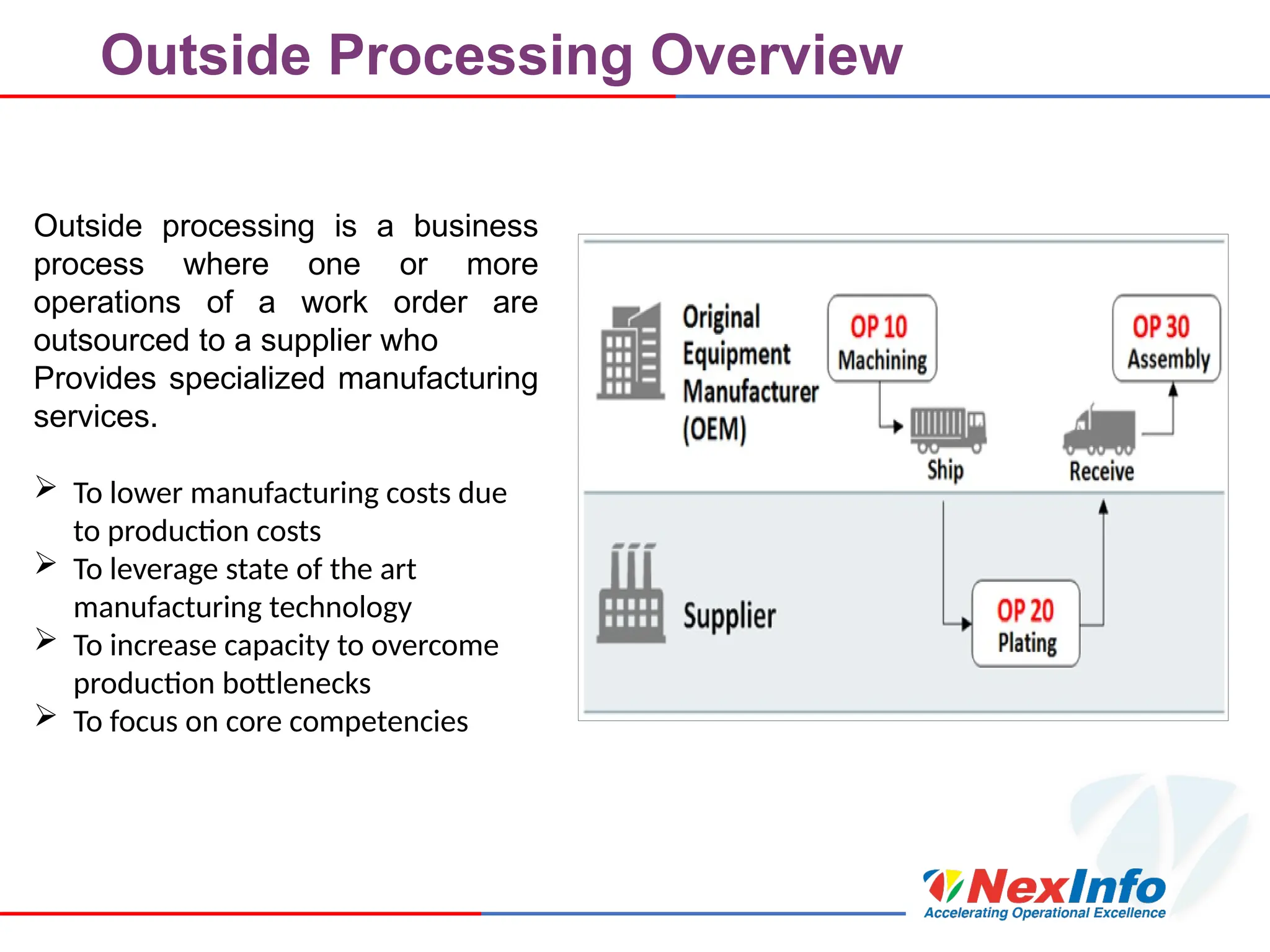

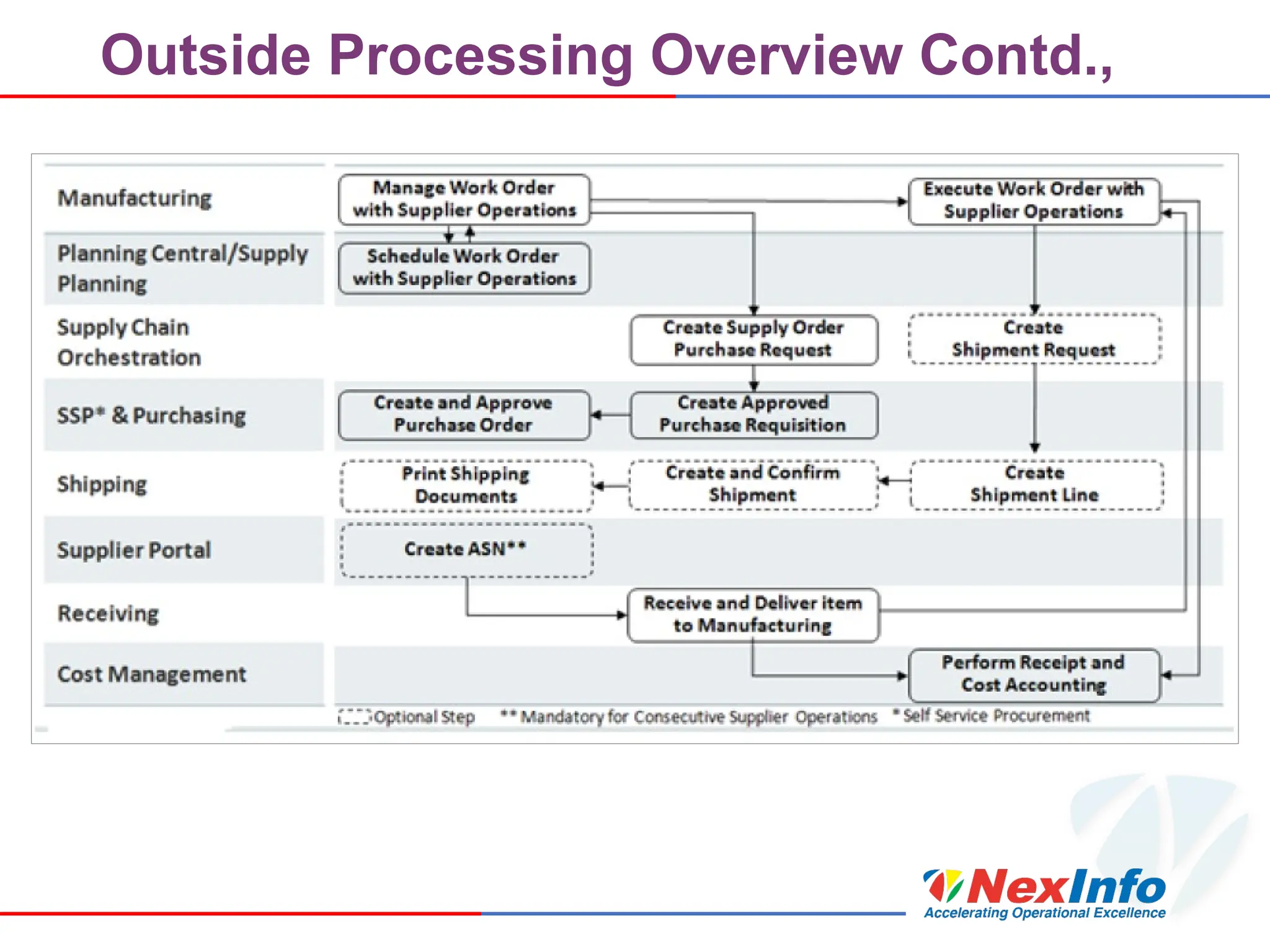

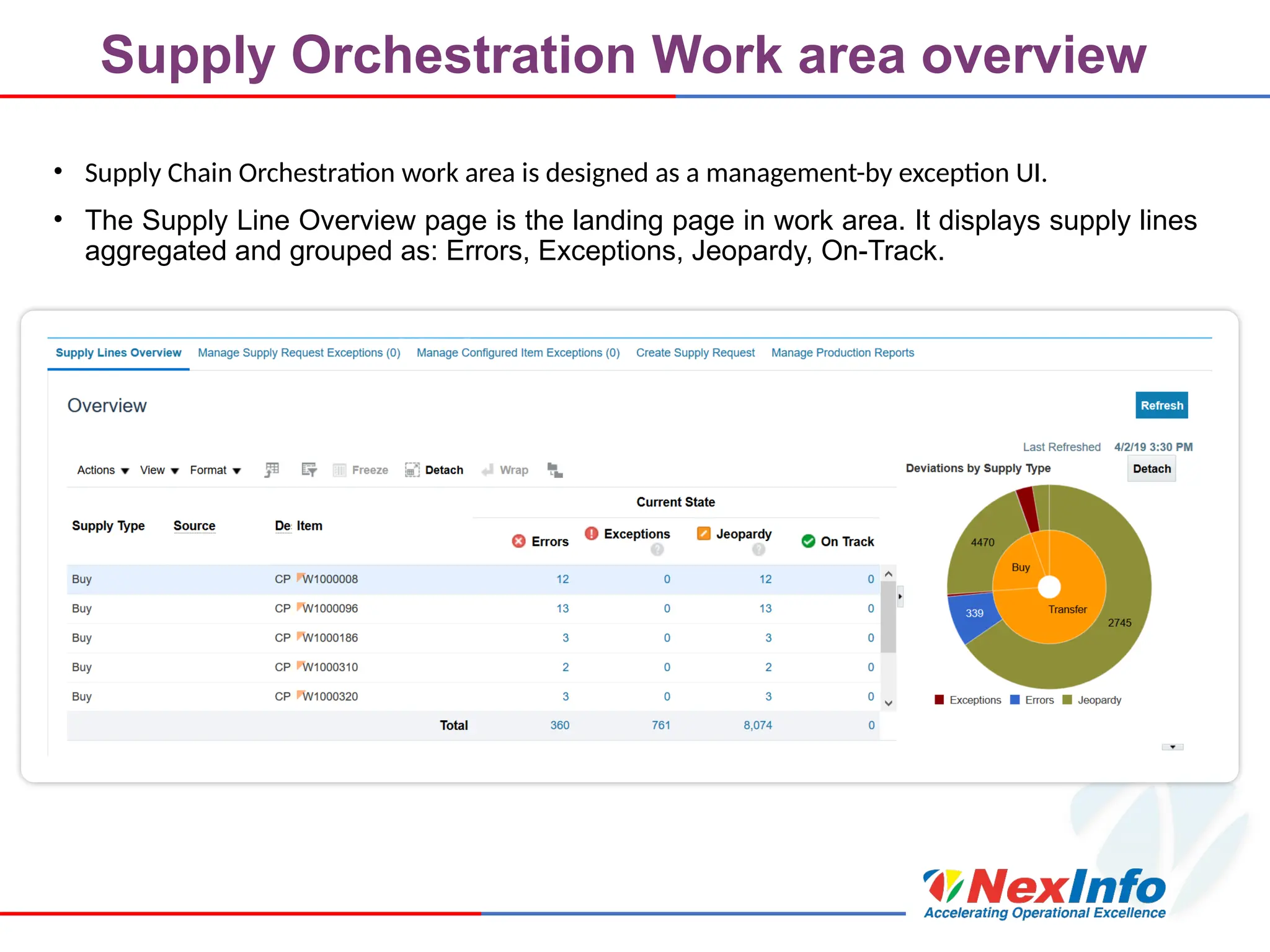

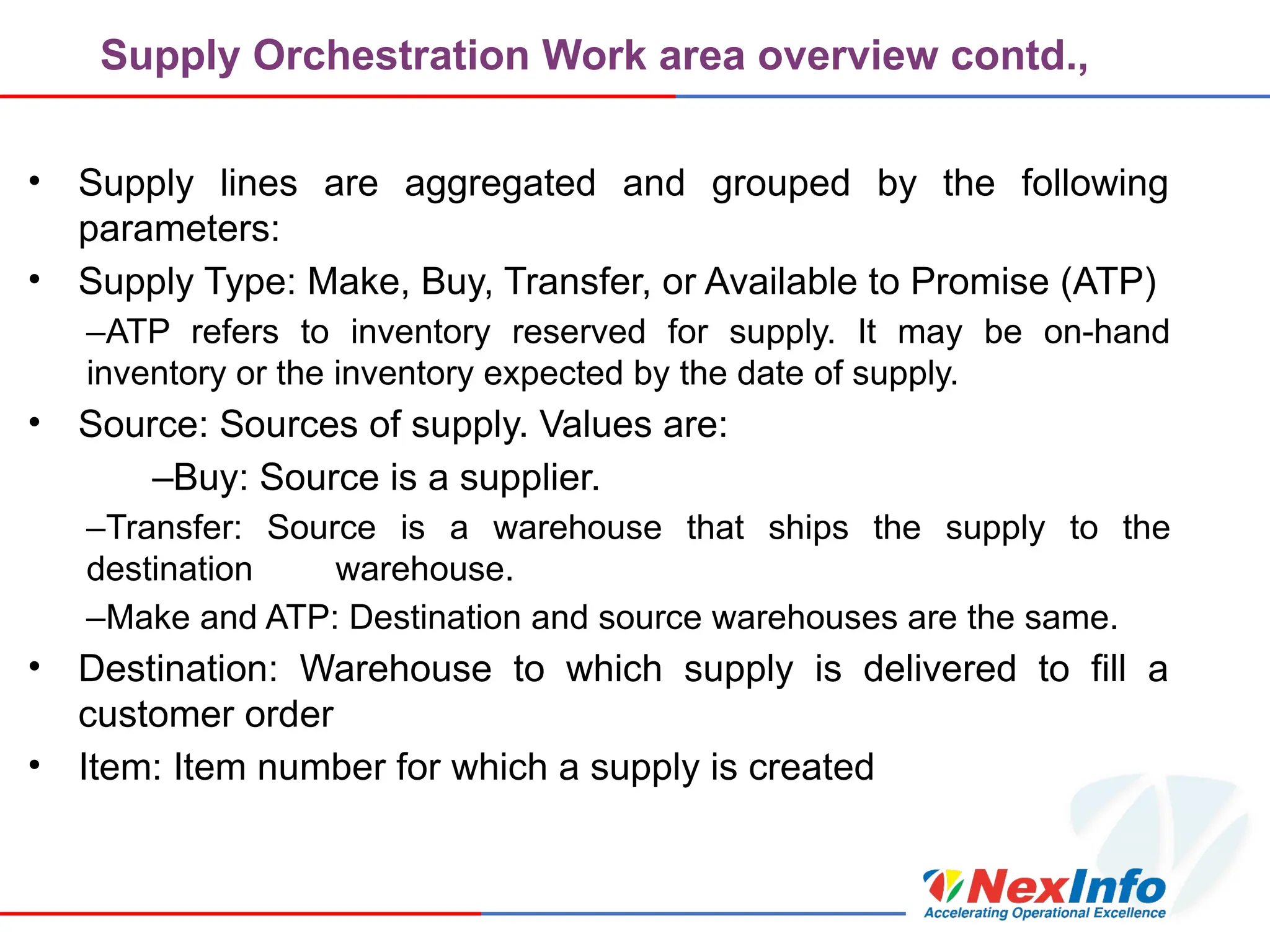

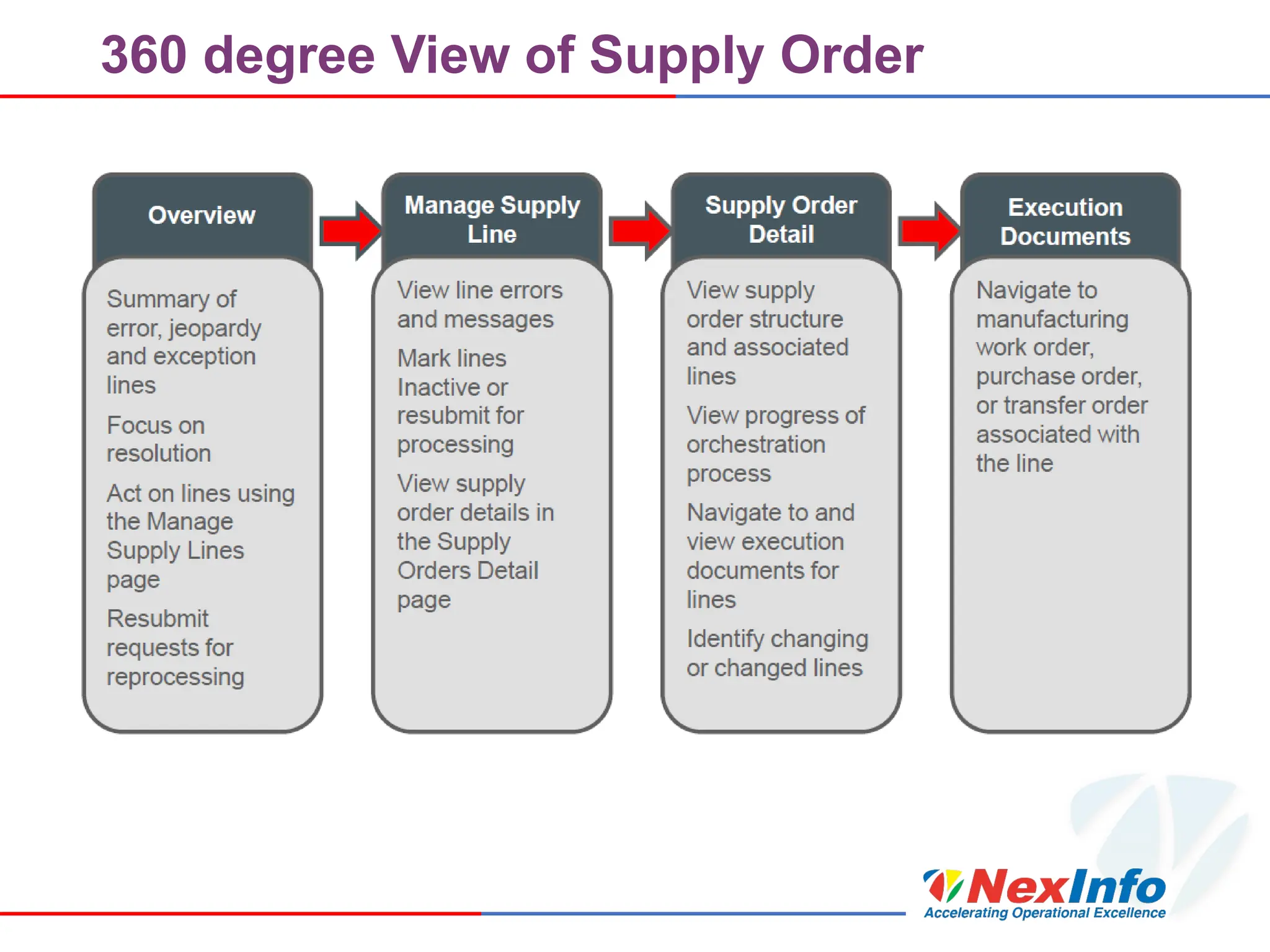

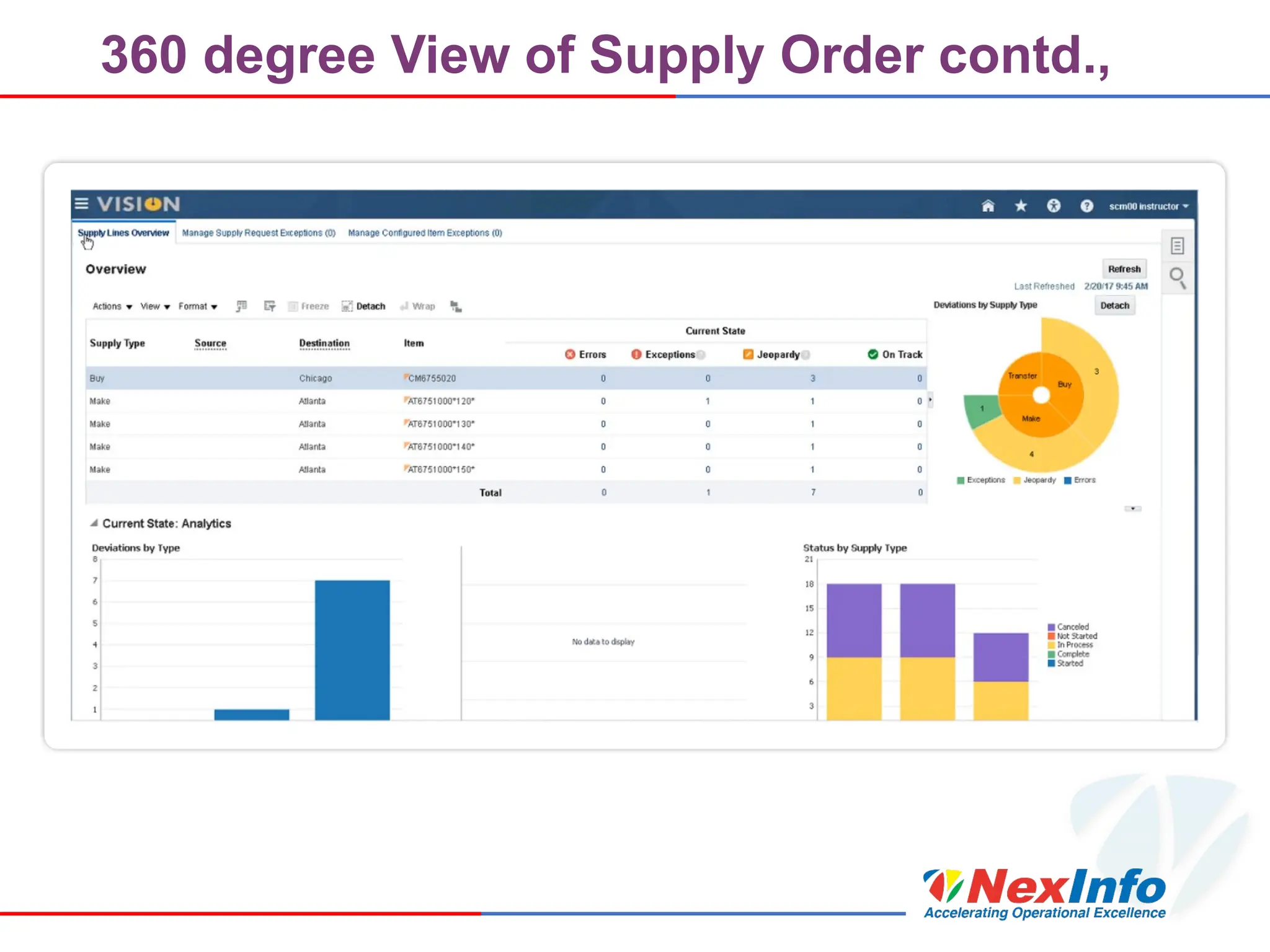

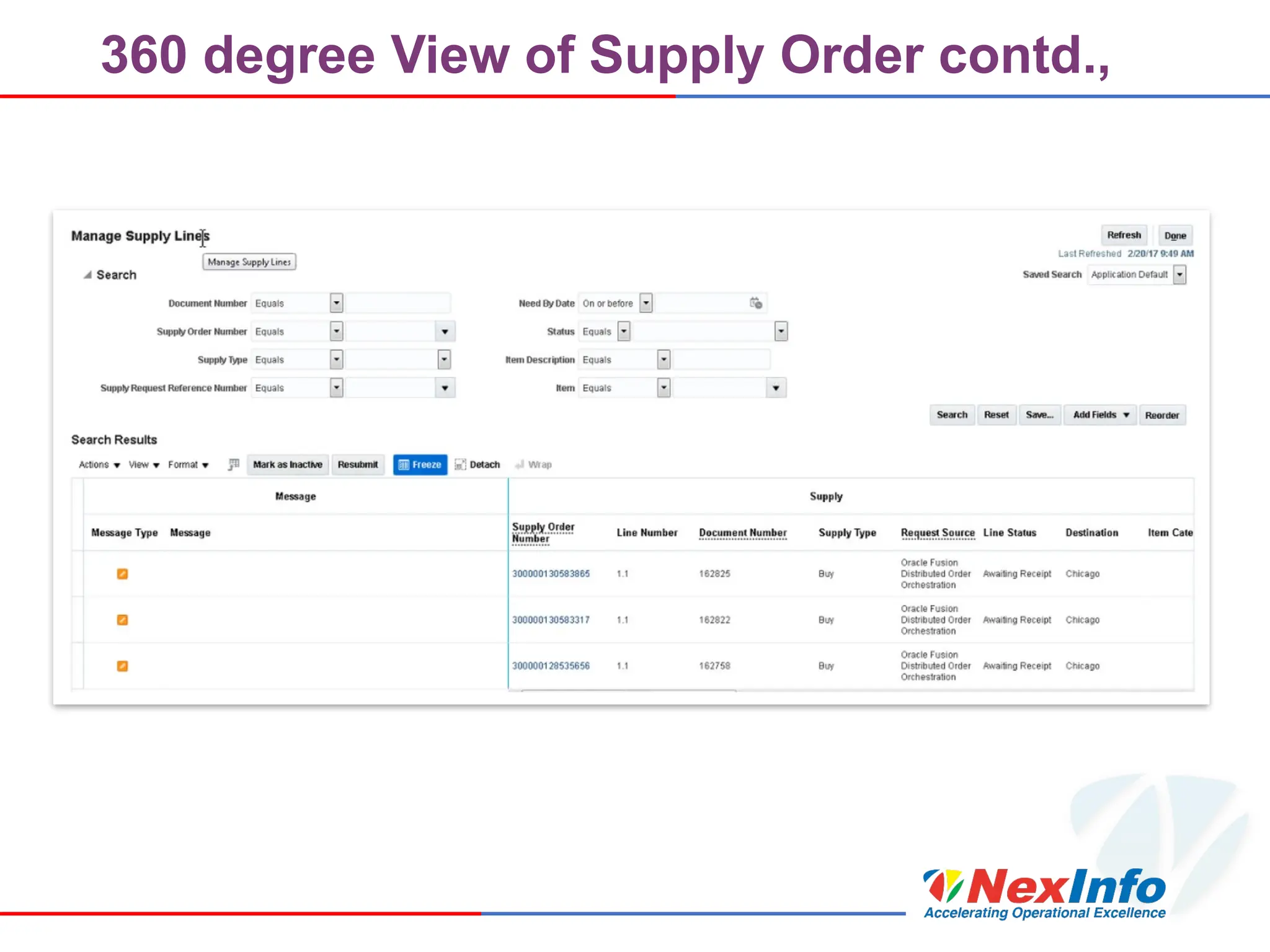

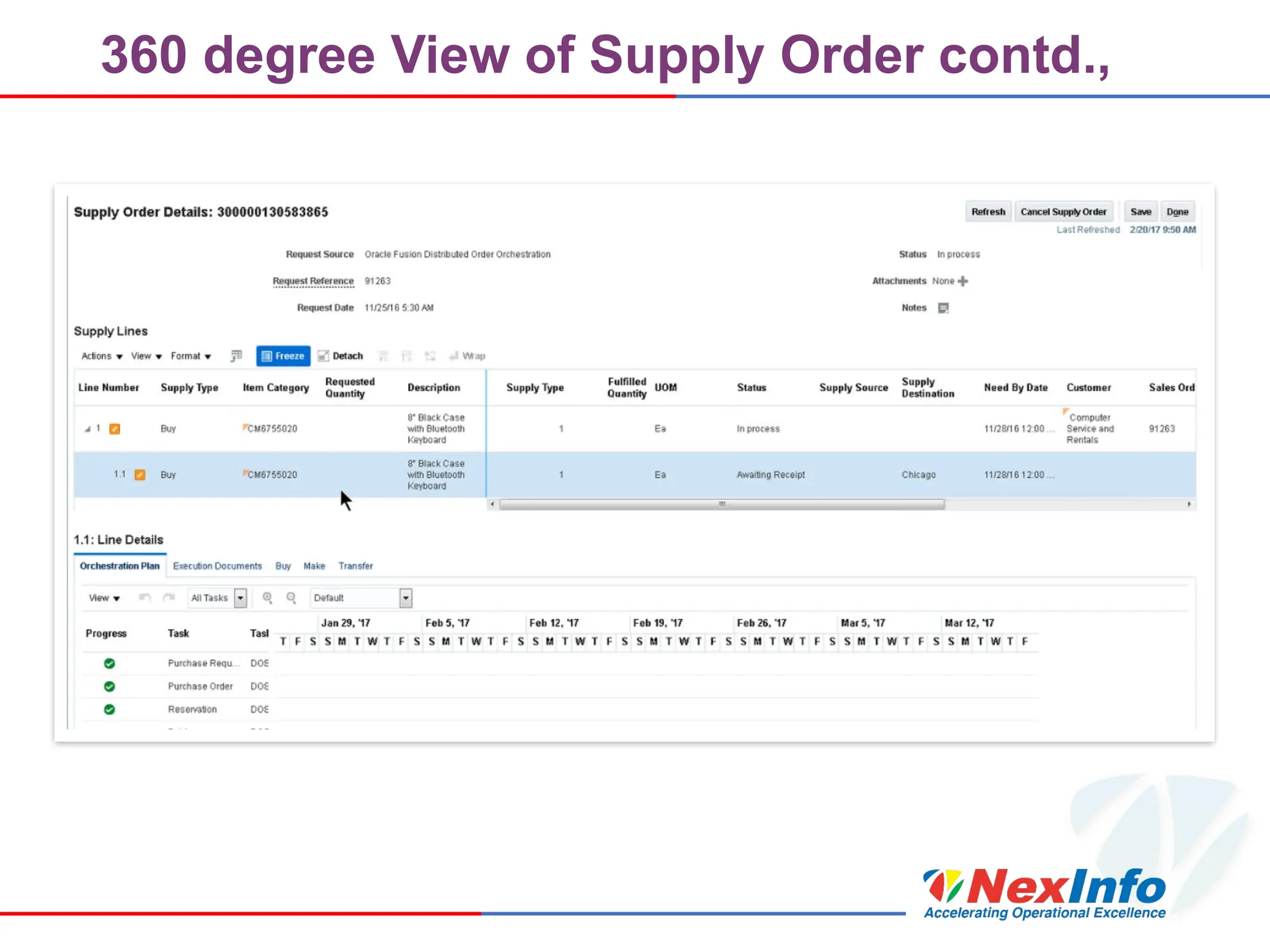

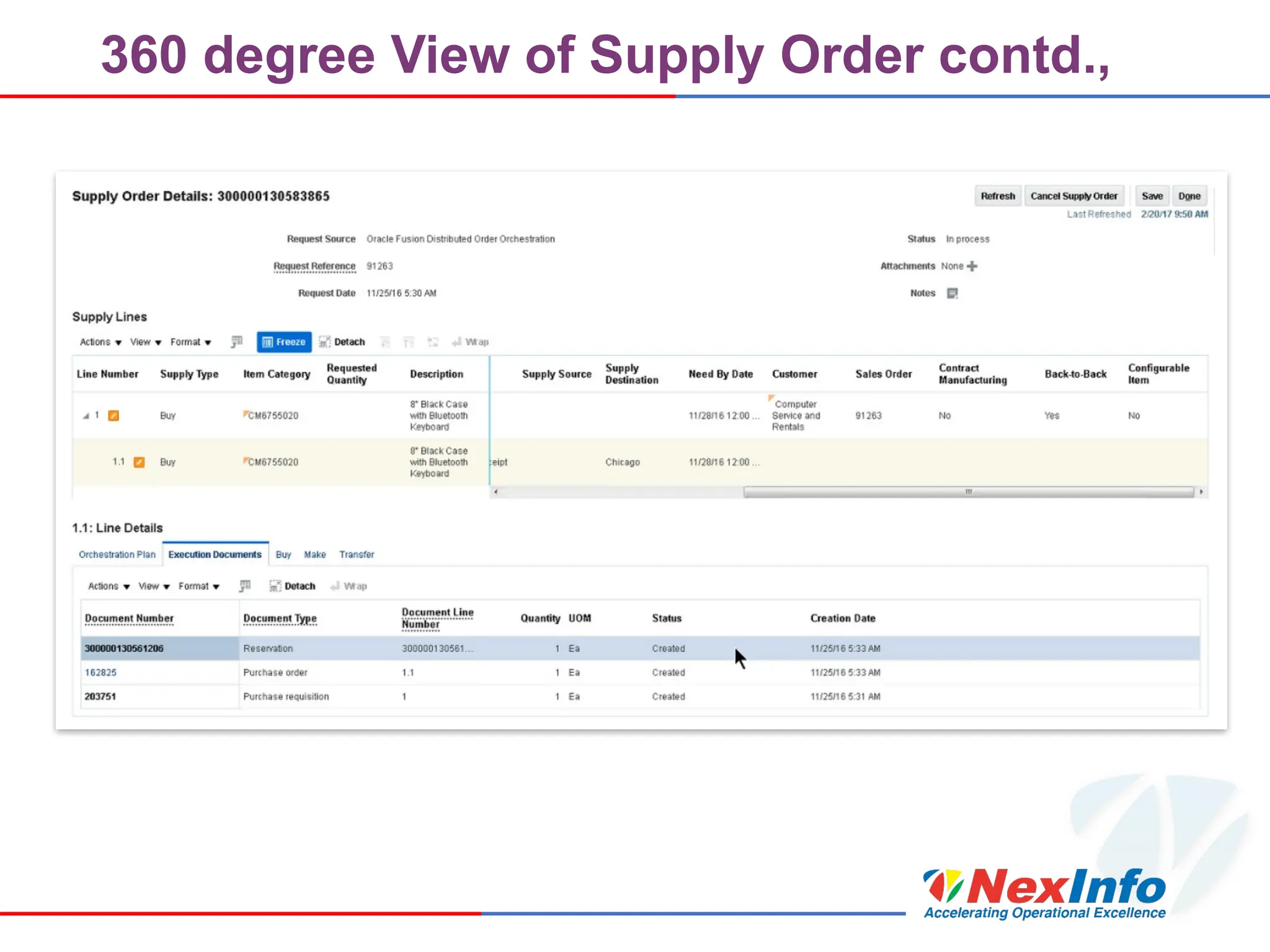

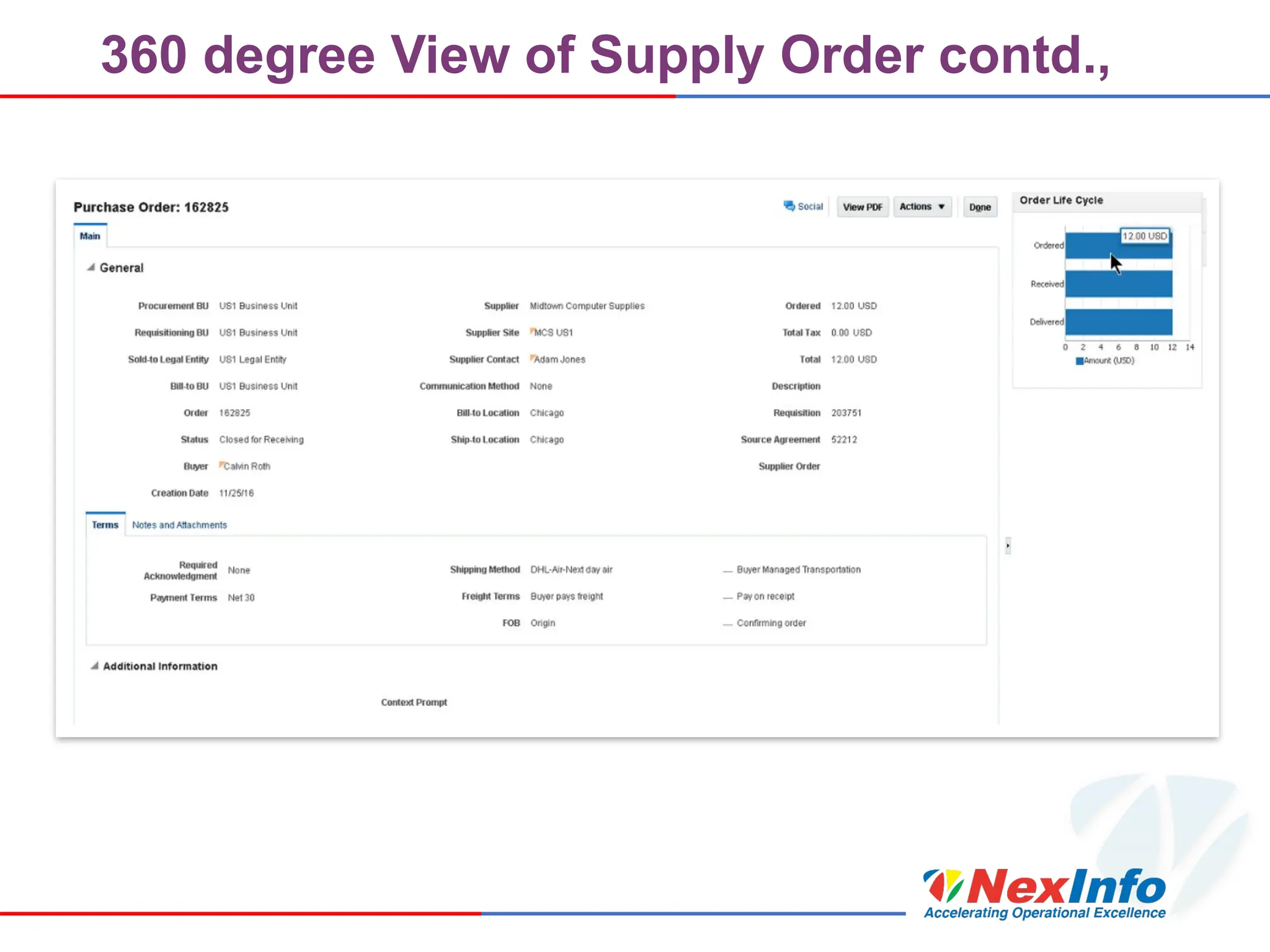

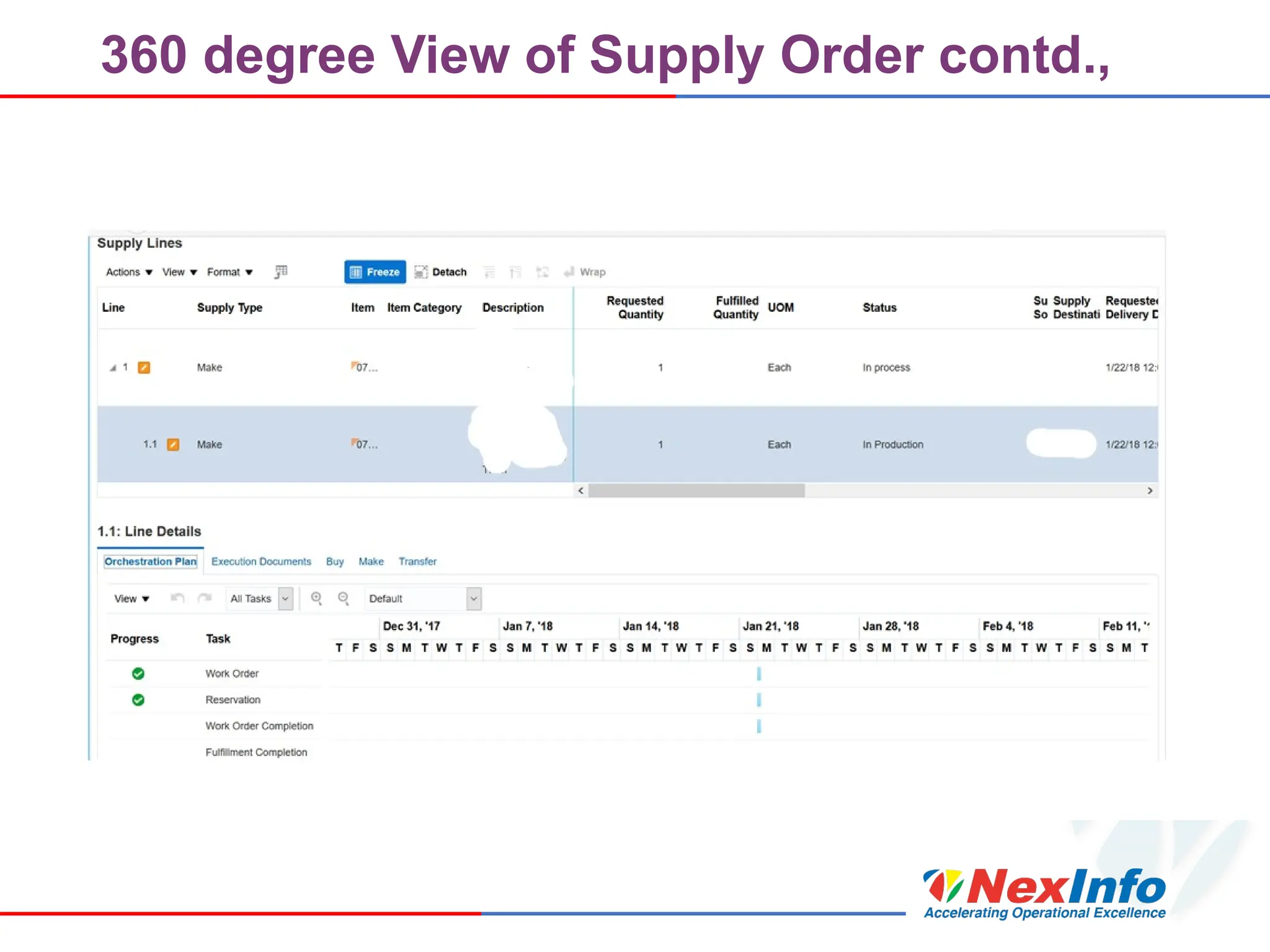

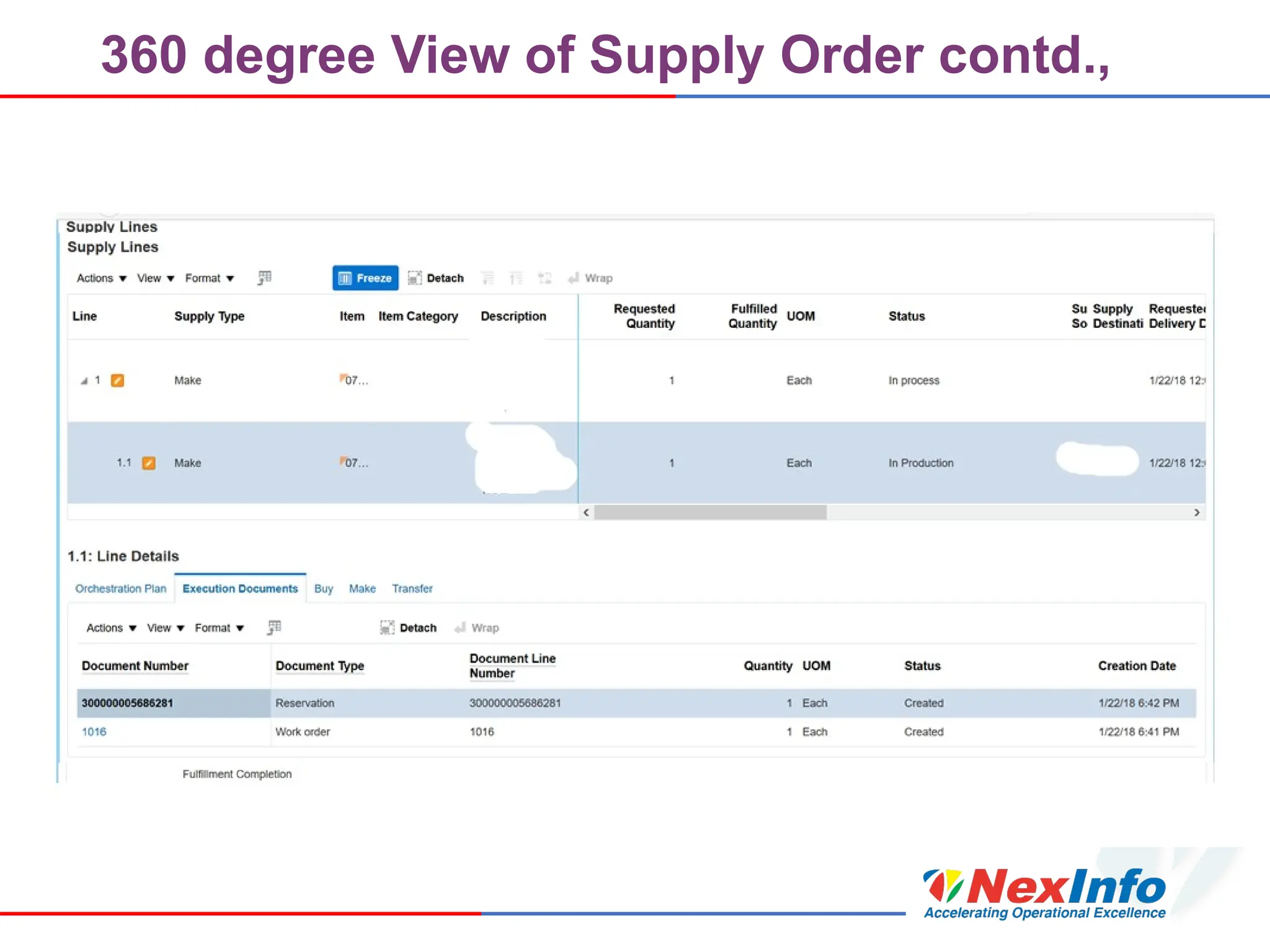

NexInfo is a consulting company established in 1999 that specializes in optimizing clients' operational excellence through a mix of business process and software consulting, focusing on areas such as supply chain management and advanced fulfillment processes. The presentation discusses advanced fulfillment techniques, supply chain orchestration, and automated change management to tackle fulfillment complexities for clients, emphasizing the importance of streamlining the order-to-fulfillment process. Key features include a comprehensive risk management interface, contract manufacturing, and outside processing to enhance efficiency in global supply chains.