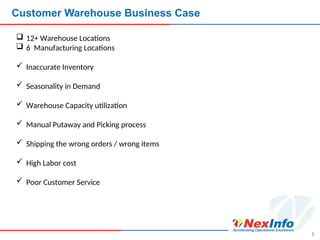

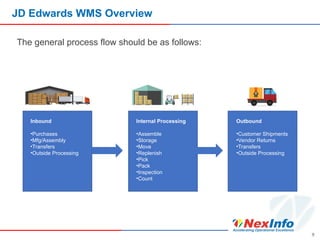

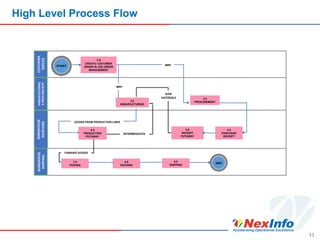

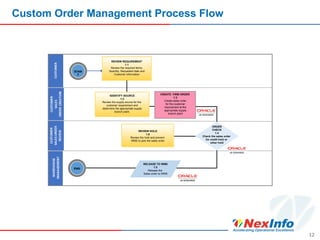

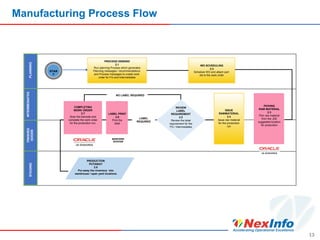

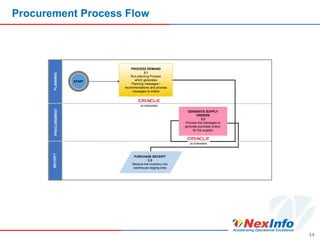

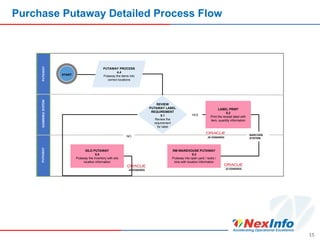

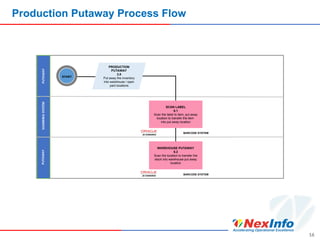

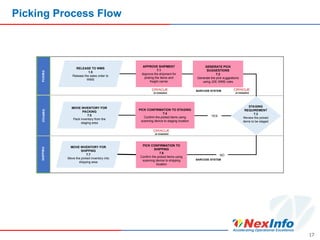

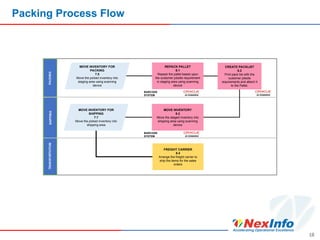

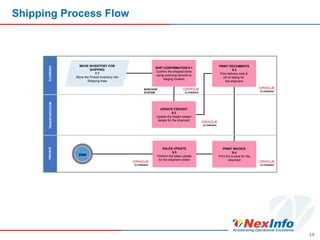

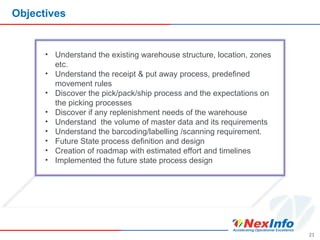

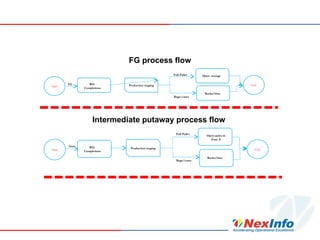

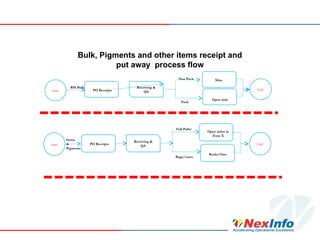

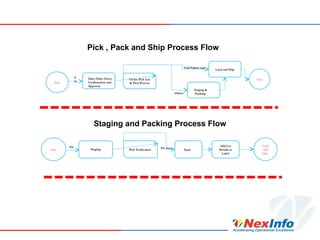

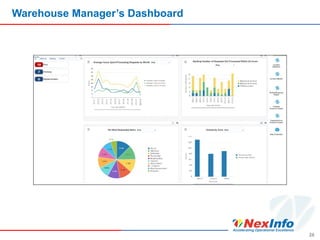

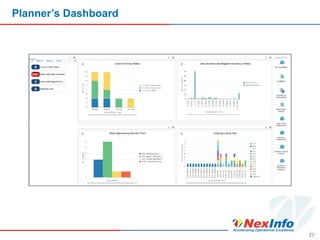

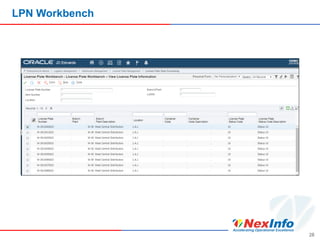

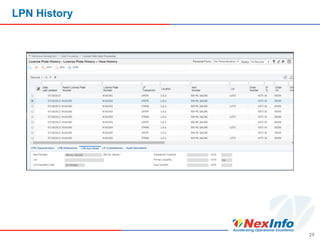

The document outlines a case study on using JD Edwards Advanced Warehouse Management System (WMS) to improve warehouse operations, highlighting NexInfo's consulting services in various business processes and software. It discusses the challenges faced by customers, such as inaccurate inventory and manual processes, and details the streamlined processes enabled by JD Edwards WMS, including put-away, replenishment, and picking. The case study also describes NexInfo's expertise, locations, and the relevance of their cloud connectors in supporting business operations.