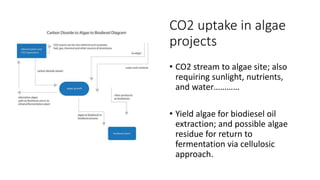

Carbon dioxide (CO2) is both a friend and foe as the greatest greenhouse gas by volume. However, downstream products that utilize CO2 as a feedstock can make it less of a foe by converting it into useful materials like plastics, fuels, chemicals and building materials. Applying and converting CO2 into products like plastics is of great interest as it can replace 50% of the petroleum-based content in some plastics and represents an important carbon reduction scheme. Beyond direct utilization, CO2 applications in enhanced oil recovery, concrete curing, algae cultivation and other industrial processes also provide environmentally friendly uses and net greenhouse gas reductions.