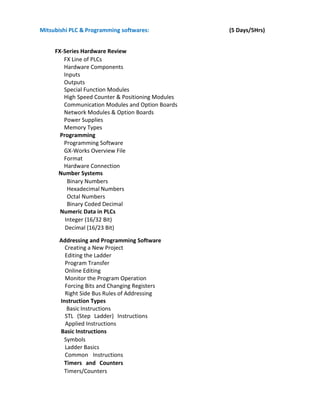

The document provides an overview of an advance automation training program covering PLC programming with Allen Bradley, Siemens, and Mitsubishi systems. It outlines curriculums for 10 days of Allen Bradley training, 7 days of Siemens training, and 5 days each for Mitsubishi and Factory IO training. The curriculums cover topics such as PLC hardware, programming software, logic instructions, timers/counters, analog control, troubleshooting, and documentation.