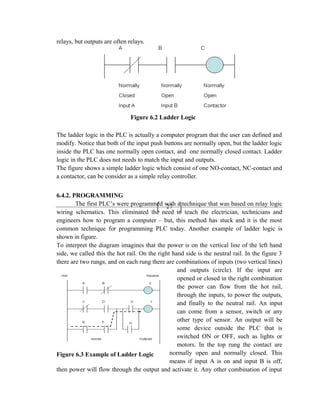

The document provides an overview of the Aditya Birla Group, a large Indian conglomerate. It discusses the company's origins in the 19th century with Seth Shiv Narayan Birla starting a cotton trading business. It expanded into various industries in the early 20th century under Ghanshyamdas Birla. The group now operates in over 40 countries with over 120,000 employees. The document also describes the cement production process used by the group's cement division, including mining of raw materials, crushing, blending, preheating and the rotary kiln production of clinker.

![Blasting: After drilling holes, this place is blasted by blasting materials inserted

inside the drilled part to break the huge rocks into pieces.

2.2 CRUSHER

These pieces of rocks are brought near to the crusher & are further processed.

Fig2.2-Raw Material Processing

The crusher crushes these collected rocks into fine pieces of 50 mm size. It just breaks

down the huge rocks into compatible sizes with Impact /hammer mechanismsm

2.3 PRE-HOMOGENIZATION OF RAW MATERIAL:

In this process this crushed material l is arranged in the form of piles

with the help of stacker, to make it available for picking it up for further

processing.

Fig 2.3-Stacker

Here definite pile size is fixed. Laterite [Iron ore] is also mixed in this process. This

piled material is then reclaimed by the Reclaimed.

5](https://image.slidesharecdn.com/rep-151027034603-lva1-app6892/85/Aditya-birla-cement-training-report-5-320.jpg)