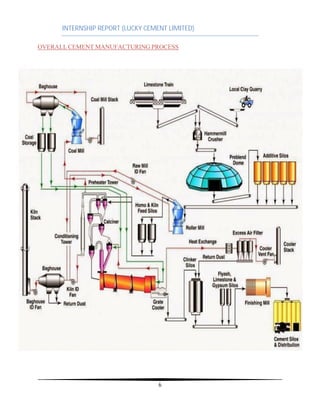

This document is an internship report by Syed Asim Ali Shah, detailing a 12-day internship at Lucky Cement Limited, covering the company's history, structure, and cement manufacturing processes. Key topics include types of cement, manufacturing methods, machinery used, and operations within the production department. The report includes acknowledgments, an executive summary of the internship experience, and various sections focusing on cement's chemical properties and production techniques.

![INTERNSHIP REPORT (LUCKY CEMENT LIMITED)

28

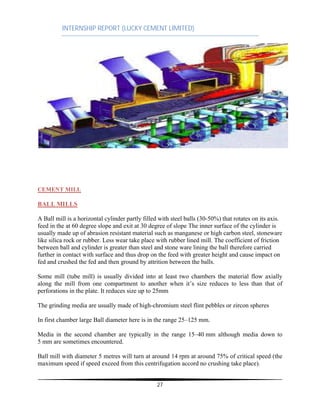

Nc = 1/2π √[g/(R-r)]

As a general rule, the size of media has to match the size of material being ground: large media

can't produce the ultra-fine particles required in the finished cement, but small media can't break

large clinker particles

In wet grinding power consumption is 30% less than dry grinding. A current of air is passed

through the mill. This helps keep the mill cool, and sweeps out evaporated moisture which would

otherwise cause hydration and disrupt material flow. The dusty exhaust air is cleaned, usually

with bag filters.

FACTOR INFLUENCE ON THE SIZE OF MATERIAL

1. Rate of feed: higher the rate of feed lesser the reduction in size.

2. The properties of the feed material: Less reduction for harder material

3. Weight of ball: Increase the weight increase the size reduction.

4. The diameter of the ball: Lesser the ball size grater the size reduction give (fine

product)

5. The slop of ball the slop of mill: Increase in the inlet material slope which increases the

capacity and reduces the retention time of crushing

6. The speed of rotation of the mill: neither lower the speed nor higher the speed in both

case reduce impact on feed thus reduce size reduction. Speed should be just lesser than

critical speed](https://image.slidesharecdn.com/luckyinternshipreport-170112145838/85/Lucky-cement-internship-report-28-320.jpg)