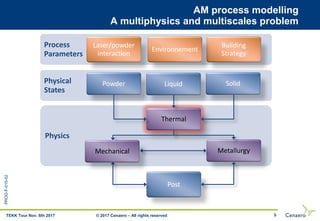

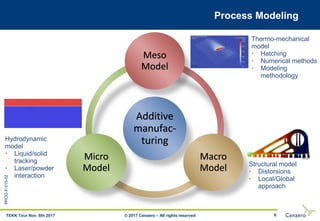

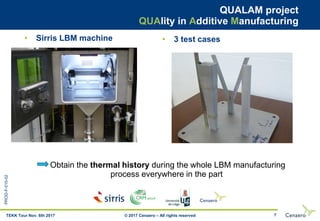

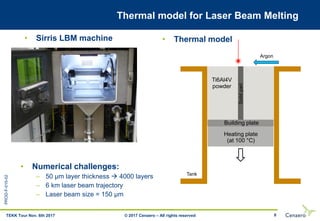

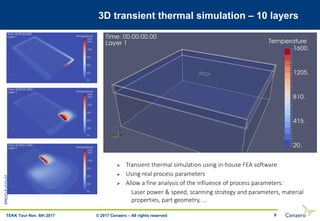

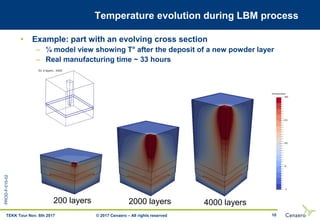

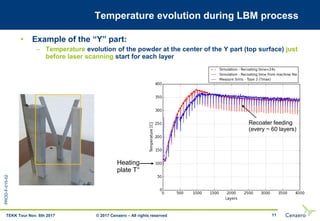

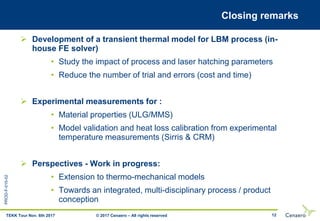

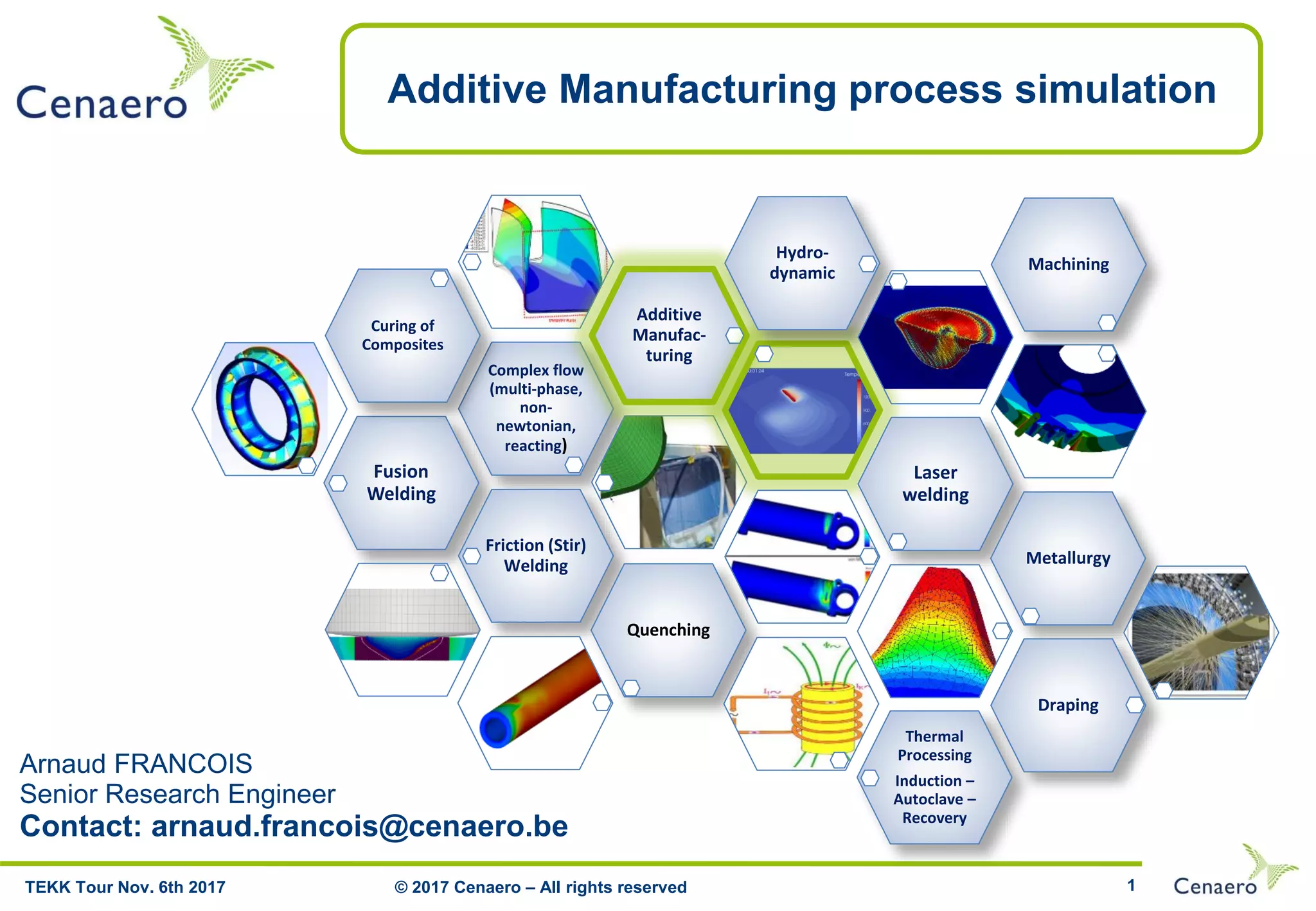

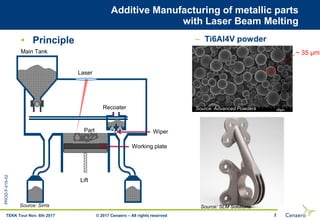

The document discusses additive manufacturing (AM) process simulation and modeling. It focuses on laser beam melting, which uses a laser to fuse powdered material to build up 3D parts layer by layer. Thermal modeling is important because AM processes involve complex thermal conditions that influence part quality and properties. The document describes a thermal modeling project that uses finite element analysis to simulate temperature evolution during the laser beam melting process and better understand defect formation. The goal is to reduce trial and error and improve process control by studying the impact of various laser parameters and strategies.

![PROD-F-015-02

4

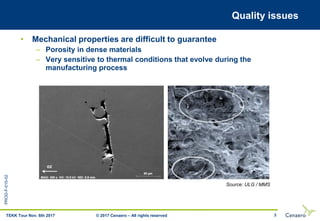

Origin of defects

• LBM process window and porosity distribution [Gong et al. 2013] :

© 2017 Cenaero – All rights reservedTEKK Tour Nov. 6th 2017

Full

dense

Lack of

fusion

Excess of

fusion

Over-

heating

Zone II

Spherical shape

Zone III

Irregular shape](https://image.slidesharecdn.com/francoiswk52-171123092615/85/Additive-Manufacturing-process-simulation-4-320.jpg)