The document is a user guide for the CP9695 Autoscanner® Pro, detailing safety precautions, equipment specifications, and procedures for using the scan tool. It emphasizes the importance of following safety instructions to prevent injury or equipment damage. The guide also provides information on diagnostic features, data management, and troubleshooting methods.

![en | 30 | User guide | CP9695 AutoScanner® Pro

579999 | REV. A | 11.2016

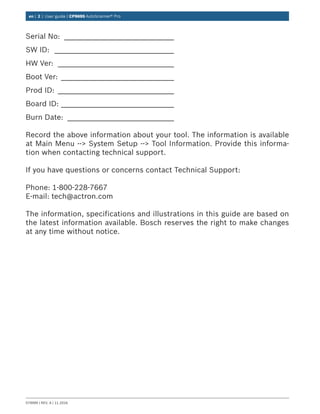

2. Observe while the scan tool validates PID MAP.

• PID MAP validation is the tool asking the vehicle

which PIDs are supported. See Appendix A for a

complete list of PIDs supported by the tool.

• Multiple PIDs may be sent if vehicle is equipped

with more than one computer module (for

example a powertrain control module [PCM]

and a transmission control module [TCM]). The

scan tool identifies them by their identification

names (ID) assigned by manufacturer (i.e. $10

or $1A).

• If one or more control module stops responding,

the scan tool displays a message.

–– If continuing, dashes will replace data in

right-hand column.

–– If NO is selected, then the scan tool

attempts to re-establish communication

with that module.

Validating PIDs

Please Wait

Waiting for vehicle to

respond

Validating PIDs

Please Wait

Validating PID List

PID 19/329

View Entire List

View Entire List shows all supported PID data for the

vehicle being tested

From Select Data to View menu:

1. Select Entire Data List.

• Use the UP and DOWN keys until Entire

Data List is highlighted.

• Press .

Select Data to View

Entire Data List

Custom Data List

English/Metric

2. View PIDs on scan tool.

• Use the UP and DOWN keys.

• See Appendix A for PID definitions.

ABS LOAD(%)

ABSLT TPS($01)

ABSLT TPS($07)

ACC POS D(%)

BARO PRS(”HG)

CALC LOAD(%)

CALC LOAD(%)

CAT TEMP11(°F)

CLR DIST(mi)

CLR DIST(mi)

0.0

6.3

6.3

0.0

29.2

0.0

0.0

73

499

513

Absolute Load Value

If Long PID Names is turned ON, the expanded text for

the PID will scroll on the bottom line of display. See

“Long PID Names” in section 3.

If the icon displays while a PID is selected press

to select PIDs to graph. A maximum of 2 PIDs can

be graphed.

Select PIDs to Graph

✓ABSLT TPS(%)

CALC LOAD(%)

COOLANT(°F)

ENG SPEED(RPM)

EQ RATIO11

IAT(°F)

IGN ADV(°)

LT FTRM1(%)

Throttle Position

• Use the RIGHT arrow key to select/deselect

PIDs. The highlighted PID from when was

pressed is already selected

• Use the LEFT arrow key to deselect all PIDs.

• Press to view graph of selected PIDs.

• When graphing two PIDs, use the UP and

DOWN keys to highlight the desired PID, which

will also display the appropriate scale.

• Press the key to pause the graph. Press

the key again to continue graphing.

• If the icon displays while a PID is selected

press to view graph.

3. Return to PID screen.

• Press .

4. Return to Select Data to View menu.

• Press .

5. Return to Datastream Menu.

• Press .

Custom List Select

The Custom Data List allows certain PIDs from the View

Entire Data List, such as those PIDs that apply to a

specific driveability symptom or system, to be selected.

From Select Data to View menu:

1. Select Custom List Select.

• Use the UP and DOWN keys until Custom

Data List is highlighted.

• Press .](https://image.slidesharecdn.com/actron9695-190116160352/85/Actron-CP9695-User-Manual-30-320.jpg)