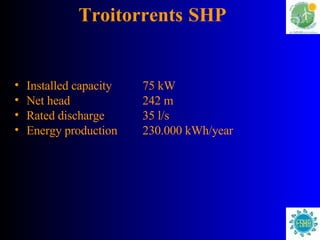

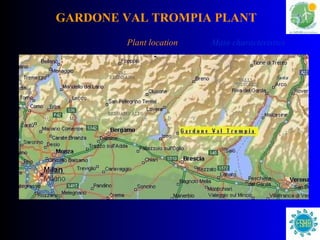

The document describes a small hydropower plant located in Troistorrents, Switzerland. The plant has an installed capacity of 75 kW and produces 230,000 kWh of energy per year. It cost a total of €185,000 to build, or €0.80 per kW of capacity. The plant utilizes a 242 meter height difference between an intake chamber and surge tank to generate power. It is suitable for isolated networks and makes multipurpose use of existing water infrastructure with no need for additional structures.

![Troitorrents SHP Costs 2.450 Specific cost [€/kW] 0,80 Specific cost [€/kWh] 185.000 TOTAL [€] 25000 Design and supervision [€] 30000 Civil works [€] 130000 Electromechanical equipment [€]](https://image.slidesharecdn.com/a3papetti3835/85/A3_Papetti-7-320.jpg)

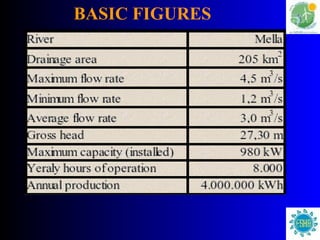

![ECONOMICS INCOME AND O&M 5,6 Gross payback ratio [years] 610.000 NET INCOME [€/year] 70.000 O&M costs [€/year] 680.000 Income [€/year] 0,17 Energy price (incl. Green Certificates 8 years) [€/kWh] 4.000.000 Energy production [kWh/year]](https://image.slidesharecdn.com/a3papetti3835/85/A3_Papetti-26-320.jpg)

![ENVIRONMENTAL BENEFITS EMISSIONS 0,12 Particulates [tons/year] 2,40 NO x [tons/year] 3,80 SO 2 [tons/year] 2.680 CO 2 [tons/year]](https://image.slidesharecdn.com/a3papetti3835/85/A3_Papetti-27-320.jpg)