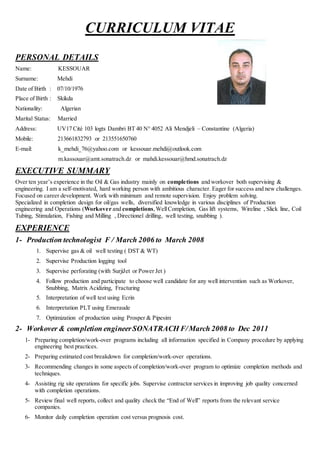

This document is a curriculum vitae for Mehdi Kessouar that includes personal details, an executive summary, work experience, education, computer literacy, and languages. Kessouar has over 10 years of experience in the oil and gas industry in completions and workover engineering. He currently works as a workover and completion supervisor where he oversees workover activities and ensures operations follow procedures. Kessouar has a Master's degree in oil and gas production from IFP School and a Bachelor's degree in production engineering.