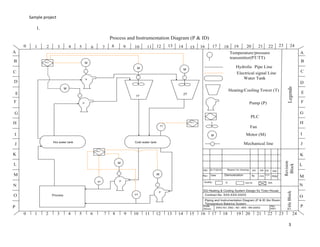

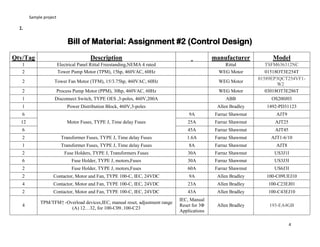

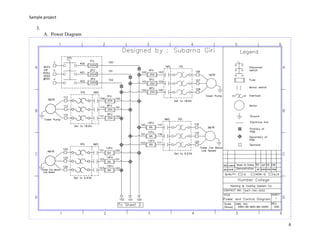

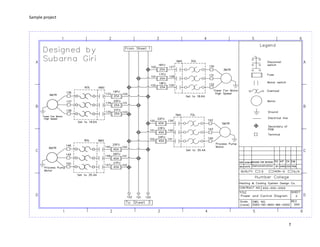

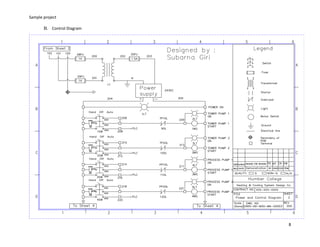

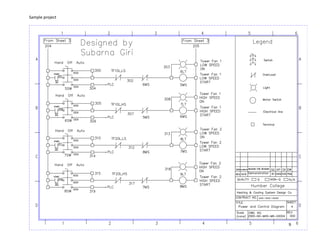

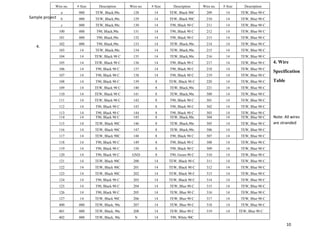

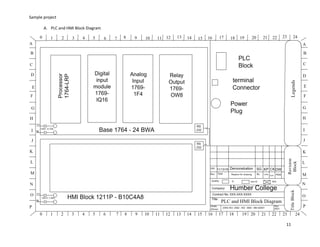

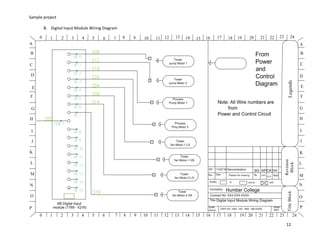

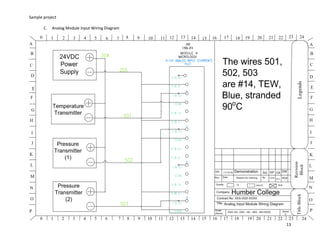

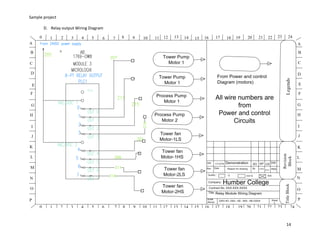

The engineering design drawings and documentation are to control the temperature and pressure of a water cooling system using a PLC and HMI. The system has two runs - a hot water run and cool water run, each with tanks. In the hot water run, hot water is pumped and cooled in towers before returning to the cool tank. In the cool run, cool water is pumped to a process and returned heated. The PLC monitors temperatures and pressures and controls pumps and fans to maintain the desired levels. Electrical schematics, I/O modules, and ladder logic are provided to interface the mechanical system with the PLC and HMI control panel.