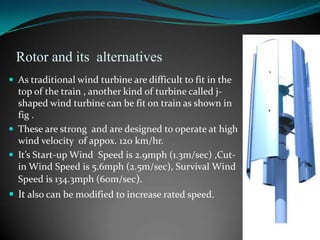

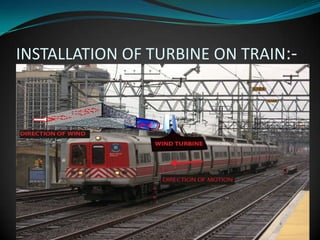

This document proposes generating electricity from wind turbines mounted on fast moving vehicles like trains. It describes different turbine designs that could be fitted to trains, including J-shaped turbines, and how they would capture and compress wind to drive generators. The turbines could power train compartments or batteries and excess power could be fed back into the electric grid. Mounting turbines on India's large fleet of trains could generate a substantial amount of renewable energy each year.