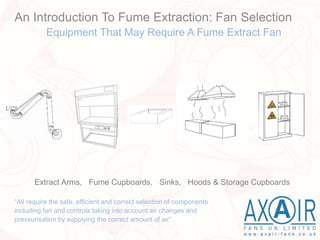

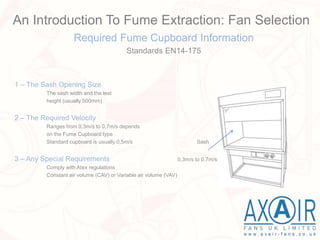

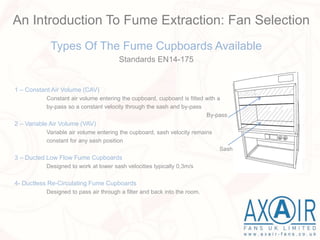

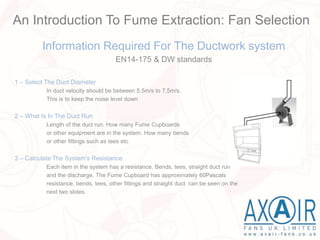

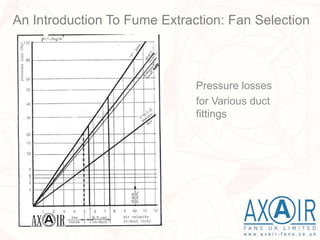

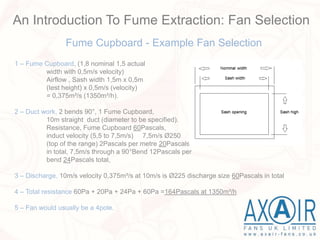

This document outlines the objectives and aims of a CPD presentation on fume extraction, covering fan selection, specification standards, control methods, and installation practices. It details necessary information for selecting fans, the importance of adhering to standards like EN 14-175, and explains different types of fume cupboards and their respective air velocity requirements. The document emphasizes the significance of correct installation and system control to ensure efficient and safe fume extraction.