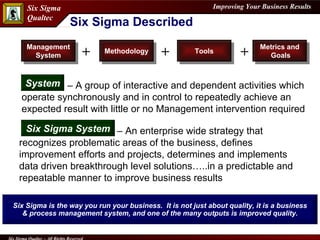

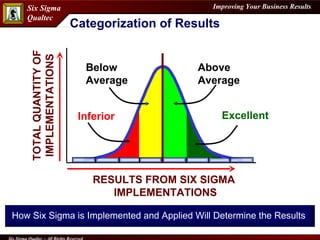

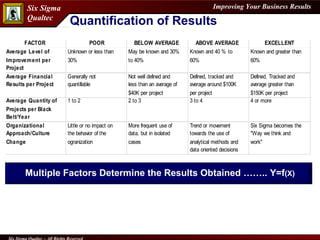

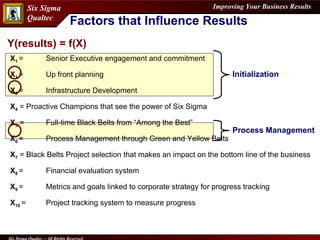

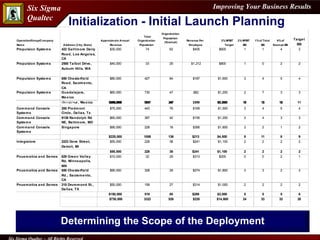

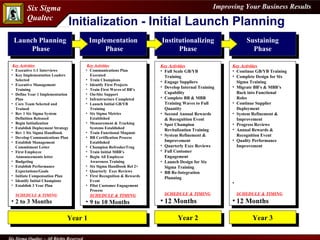

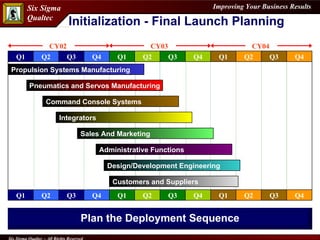

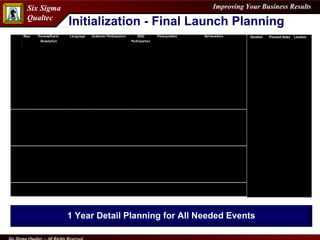

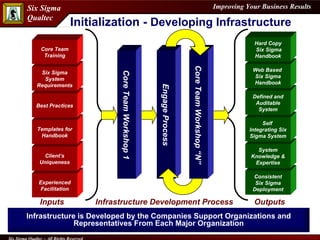

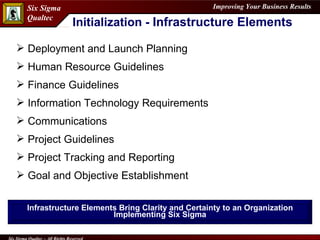

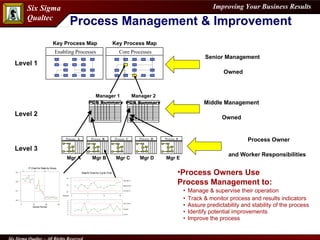

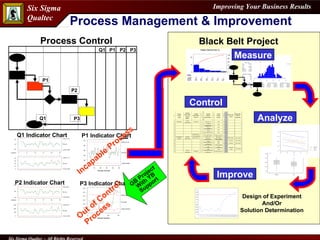

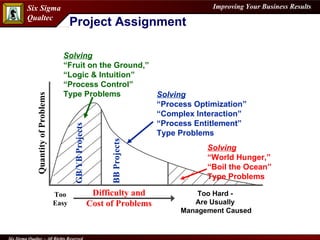

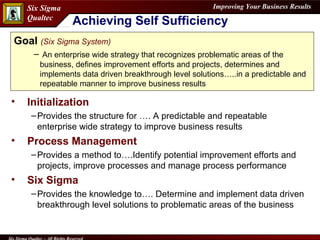

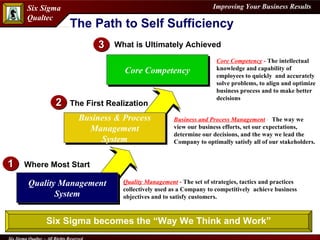

The document discusses the deployment approach for Six Sigma from initialization to self-sufficiency. It describes establishing the necessary infrastructure, which includes developing guidelines for human resources, finance, information technology, communications, and projects. It also discusses determining goals and metrics, implementing process management, and planning the deployment sequence over multiple years to eventually reach self-sufficiency.