Embed presentation

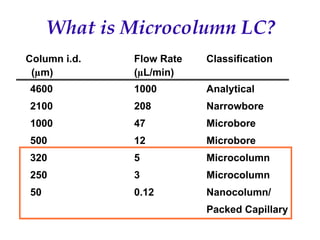

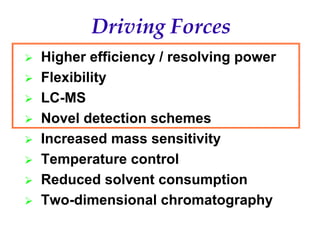

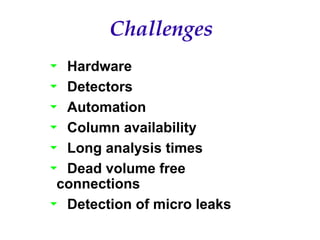

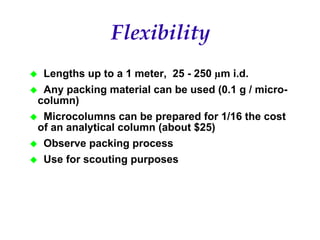

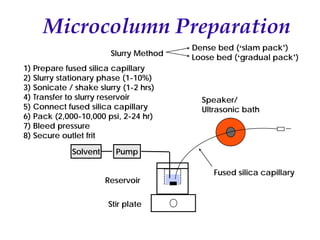

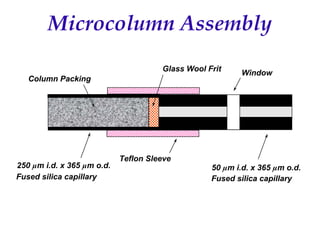

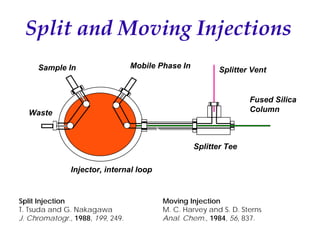

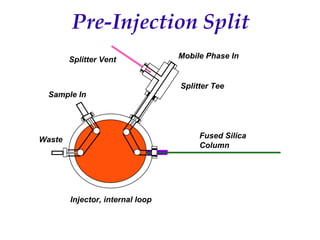

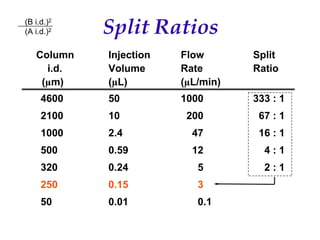

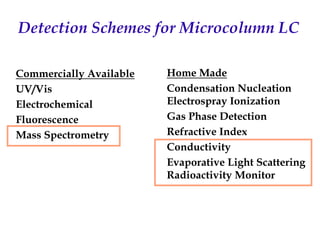

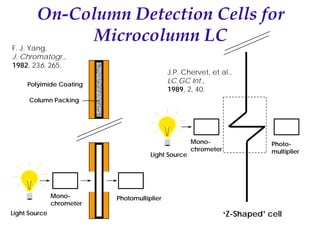

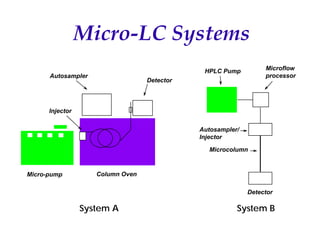

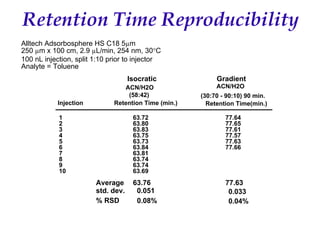

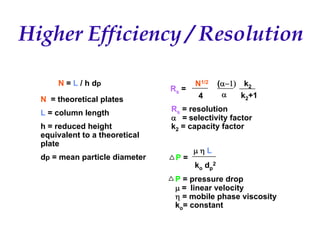

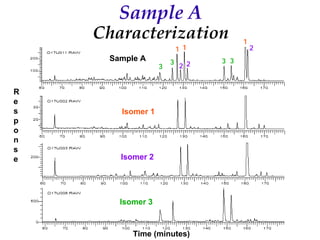

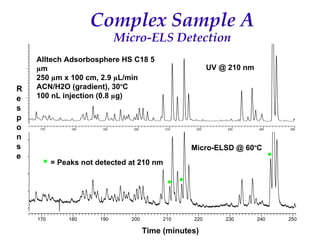

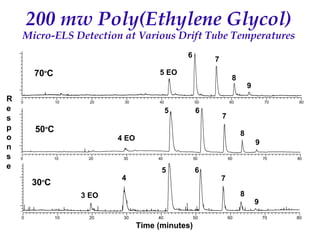

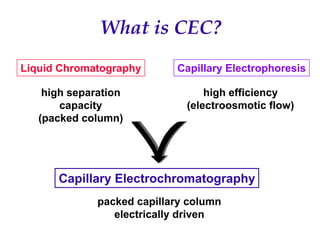

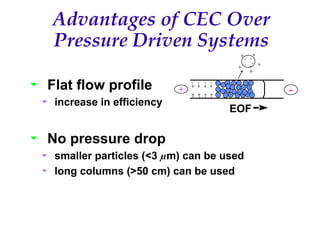

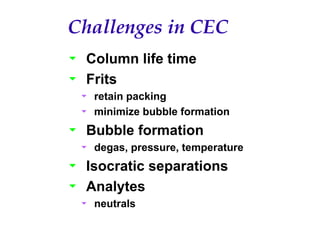

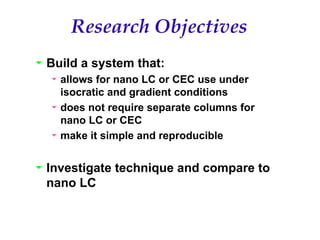

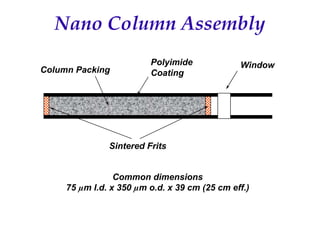

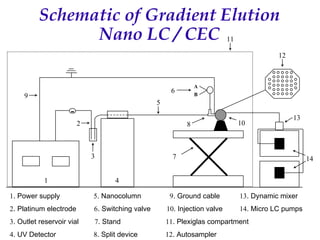

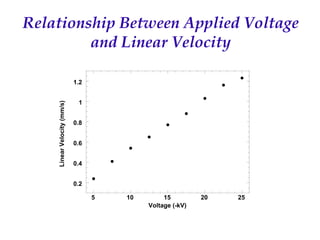

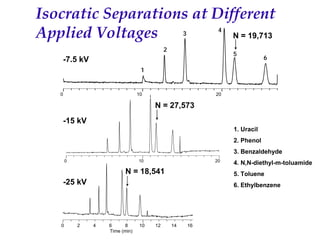

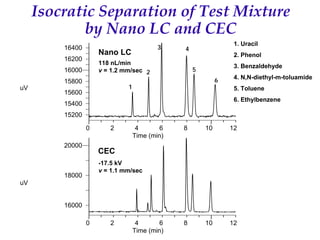

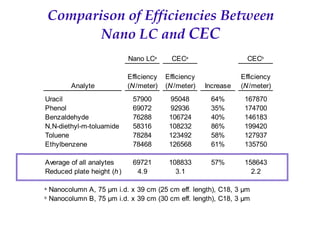

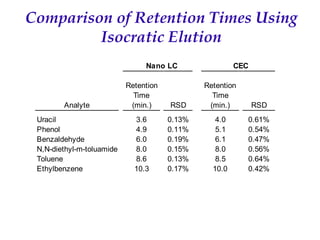

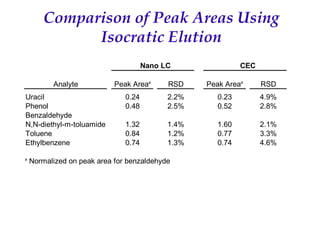

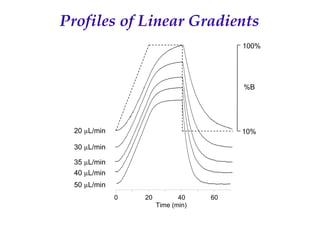

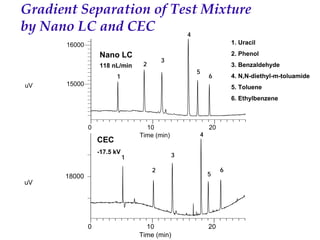

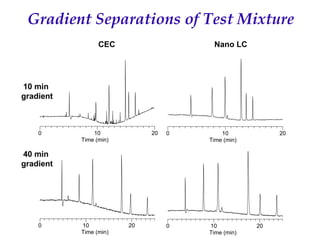

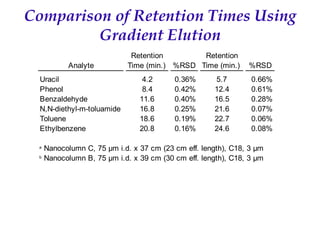

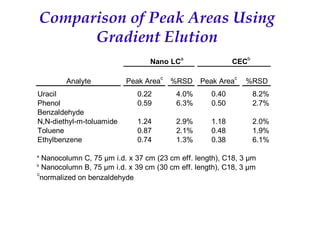

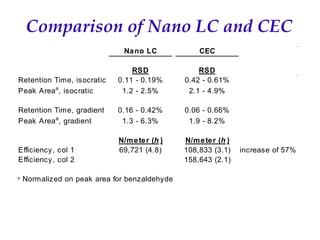

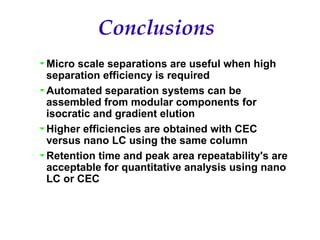

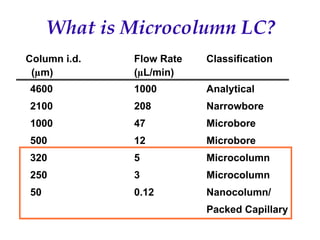

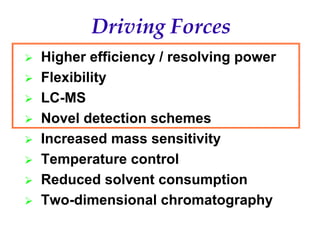

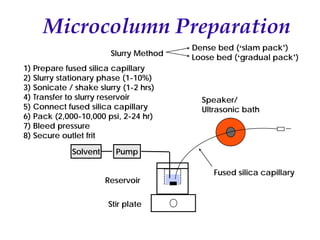

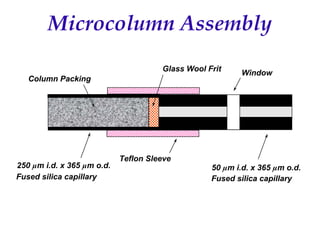

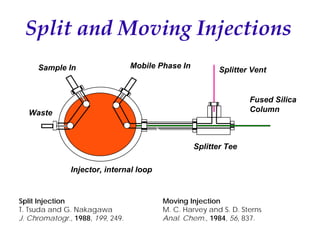

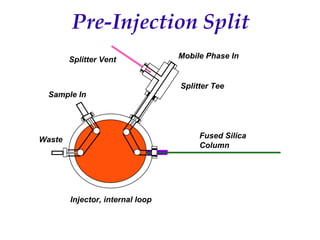

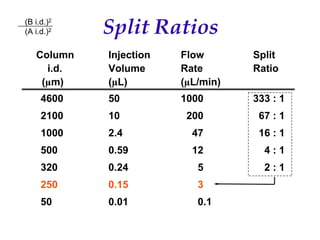

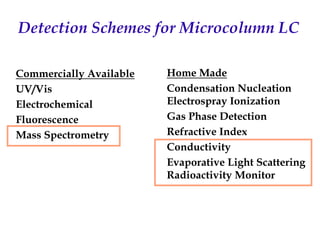

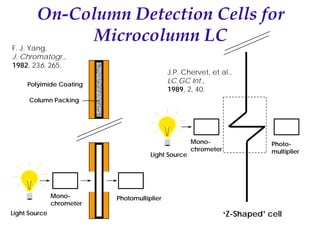

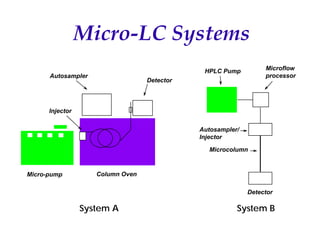

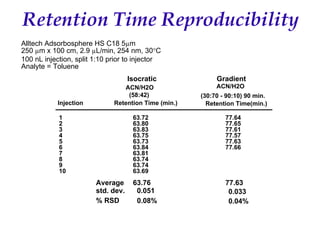

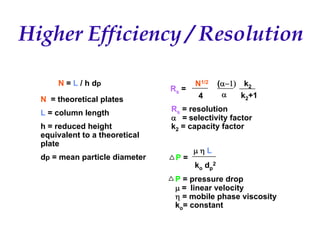

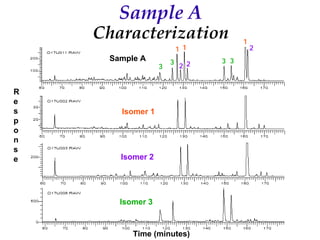

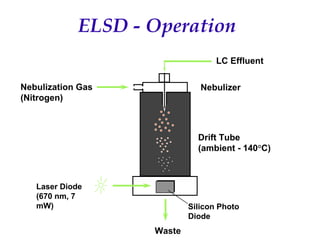

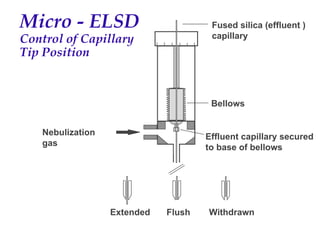

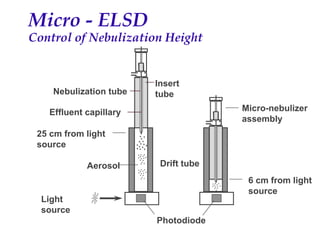

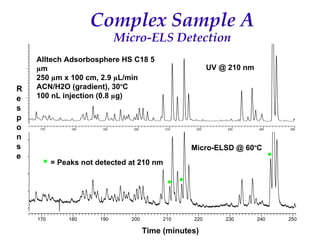

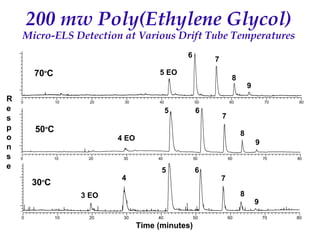

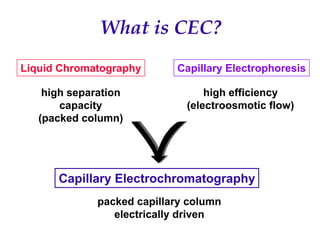

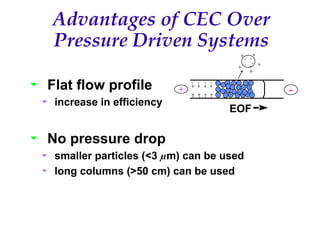

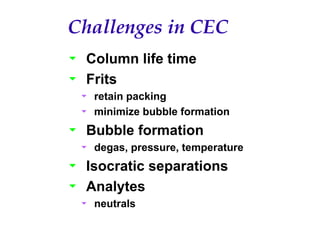

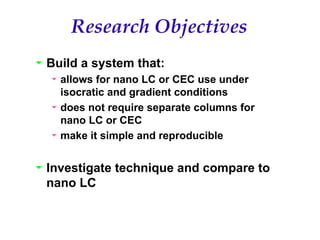

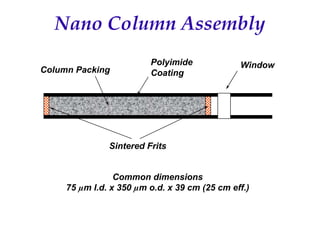

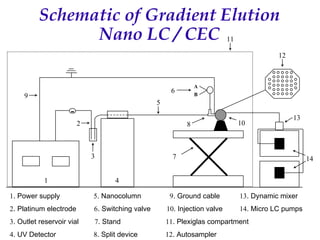

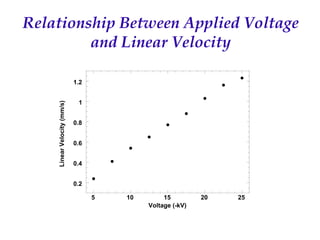

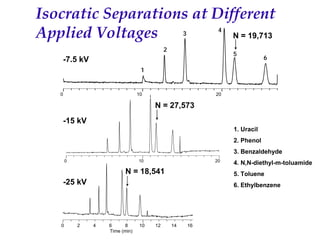

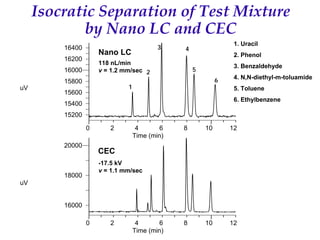

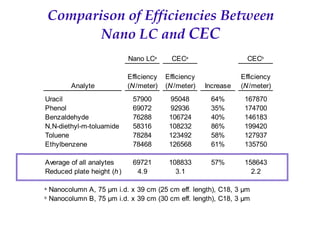

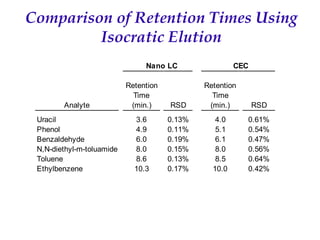

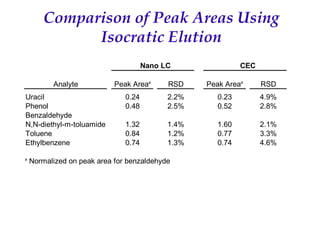

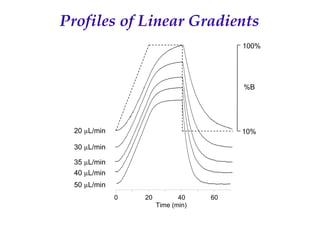

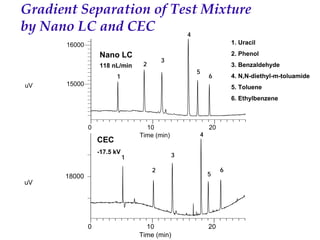

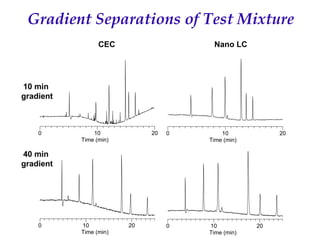

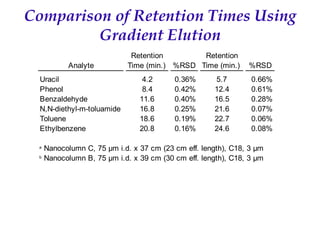

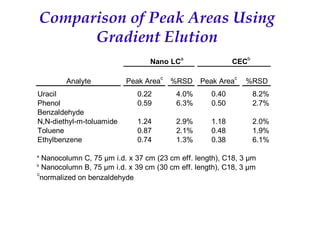

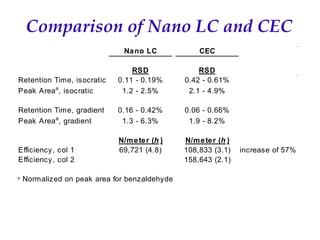

The document presents recent advancements in microcolumn liquid chromatography (LC) and capillary electrochromatography (CEC), detailing instrument considerations, high-resolution separations, and comparison between nano LC and CEC. Key points include the efficiency, effectiveness, and cost benefits of microcolumns, along with proposed hardware and detection schemes to improve chromatographic analysis. The challenges in implementation and the performance improvements achieved in terms of resolution are also discussed.