This document provides information on various services and materials available from Dinsmore & Associates, including rapid prototyping methods like stereolithography and 3D printing, plastic casting, CNC machining, and injection molding. It then focuses on the material properties and applications of the DSM Somos ProtoGen O-XT 18420 photopolymer resin, which produces accurate parts suitable for general purpose applications and various industries through the stereolithography rapid prototyping process. Physical, mechanical, thermal, and electrical properties of the resin are specified.

![SERVICES AVAILABLE

Product Design

Rapid Prototyping

Stereolithography

HDSLA

PolyJet

DSM Somos: ProtoGen 18420

SLS

DMLS General Purpose, Accurate, Epoxy Resin for Stereolithography

FDM For Solid State (355 nm) Laser Systems

Plastic Casting A White Material That Mimics Engineering Plastics

CNC Machining

Injection Mold Tooling

Description

Rapid Tooling

DSM Somos® ProtoGen O-XT 18420 is a liquid, ABS-like, photopolymer that produces accurate parts

Production Tooling ideal for general purpose applications. ProtoGen resins are the first SL resins to demonstrate different

Injection Molding material properties based on machine exposure control. Based on Somos oxetane chemistry, ProtoGen

Metal Casting O-XT 18420 offers superior chemical resistance, a wide processing latitude and excellent tolerance to a

broad range of temperatures and humidities, both during and after build.

Application

This high-temperature, ABS-like photopolymer is used in the solid imaging process to build three-

dimensional parts. Somos® ProtoGen O-XT 18420 provides considerable processing latitude and is ideal

for the medical, electronic, aerospace and automotive markets that demand:

- Accurate RTV patterns

- Durable concept models

- Highly accurate parts

- Humidity and temperature tolerant parts

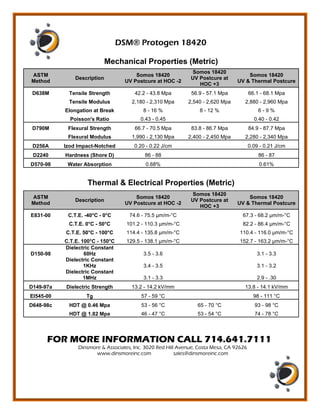

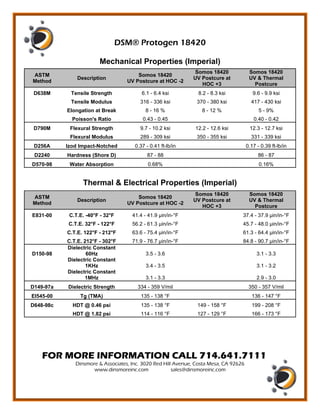

Physical Properties – Liquid

3020 Red Hill Avenue Appearance White

Costa Mesa, CA 92626 Viscosity ~350 cps at 30°C

Phone 714.641.7111 Density ~1.13 g/cm3 at 25°C

Fax 714.641.3111

Optical Properties at 355 nm

Ec 6.73 mJ/cm2

[critical exposure]

For more information on

Dp 0.11 mm (0.00434 inch)

any of our products or

services please visit us on [slope of cure-depth vs. ln(E) crve]

the Web at: E10 67.6 mJ/cm2

[exposure that gives 0.254 mm (0.010 inch) thickness]

www.dinsmoreinc.com

Email:

sales@dinsmoreinc.com](https://image.slidesharecdn.com/protogen18420materialsheet-1264524493358-phpapp01/75/Protogen-18420-Material-Sheet-1-2048.jpg)