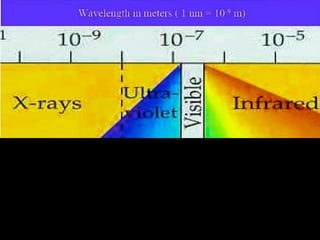

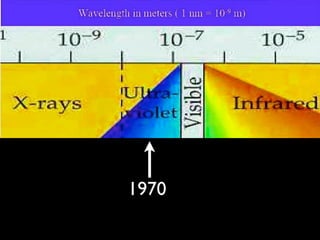

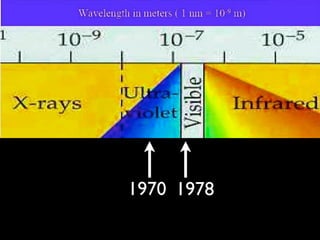

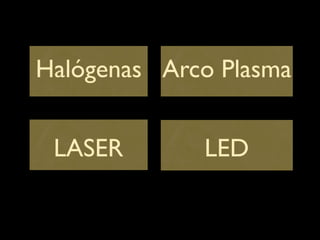

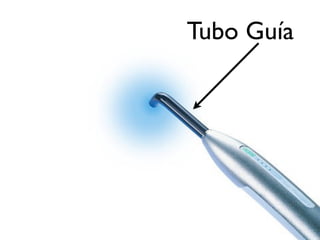

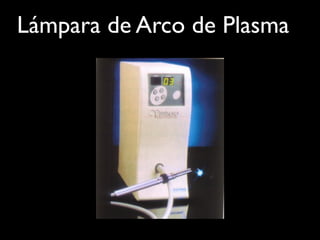

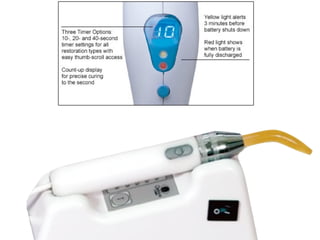

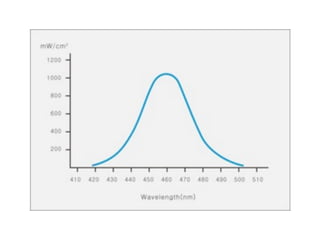

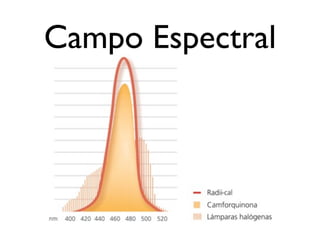

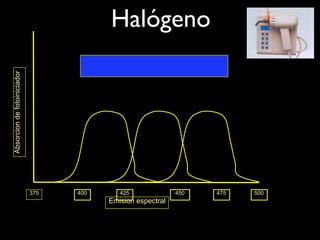

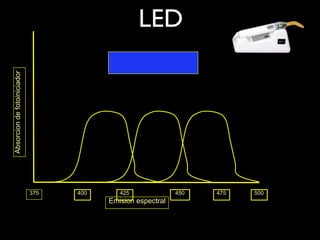

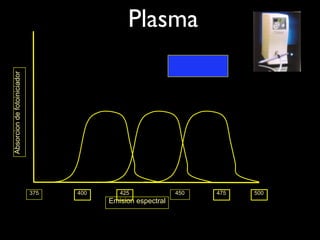

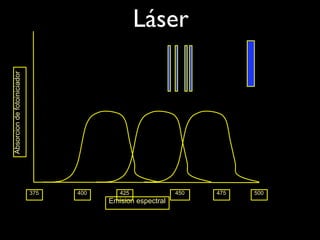

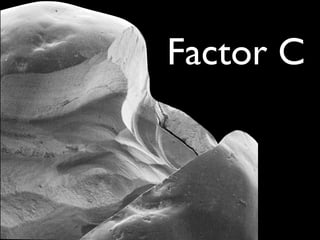

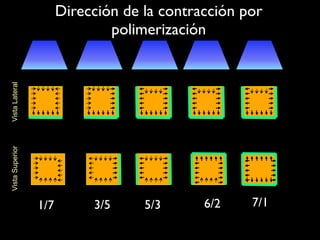

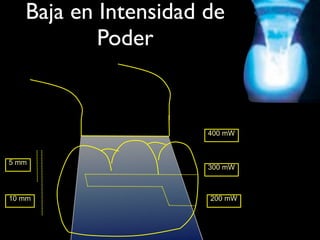

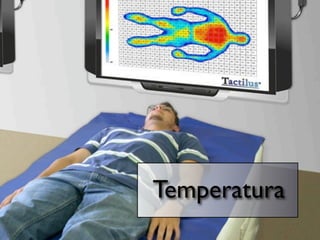

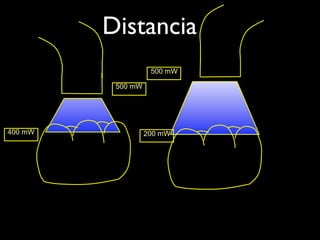

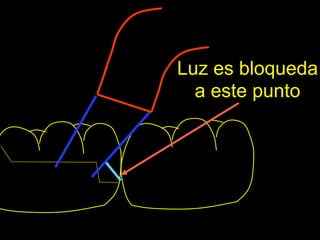

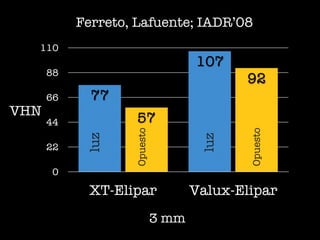

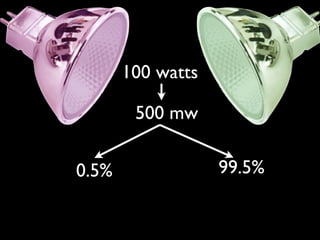

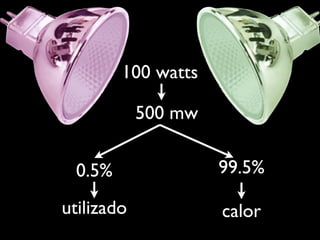

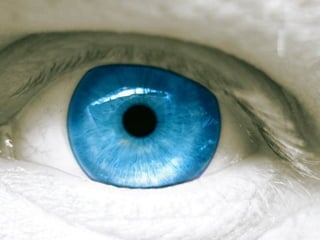

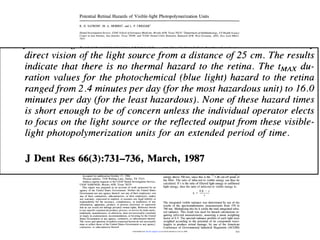

The document discusses the potential for retinal damage from visible-light photopolymerization units, focusing on both thermal and photochemical hazards associated with various light sources. It evaluates the spectral radiance profiles of 11 different units and calculates maximum permissible exposure durations to assess the risk of damage to the retina. The study concludes that while there is a risk of photochemical damage, thermal hazards are minimal unless exposed to intense light for extended periods.