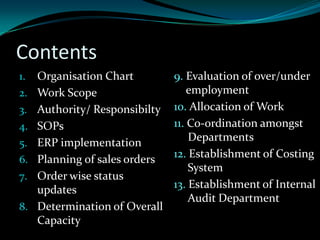

This document outlines steps to improve internal controls for small manufacturing companies, including establishing an organizational chart, determining work scopes and responsibilities, implementing standard operating procedures, planning sales orders, updating order statuses, determining production capacity, evaluating staffing needs, allocating work, coordinating departments, establishing costing and internal audit systems, and implementing an ERP system. The presentation provides details on documenting processes, monitoring adherence to procedures, and continually reviewing and improving internal controls.