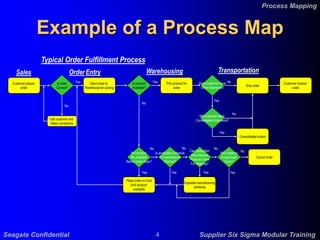

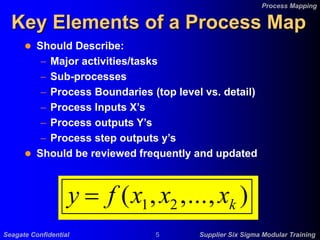

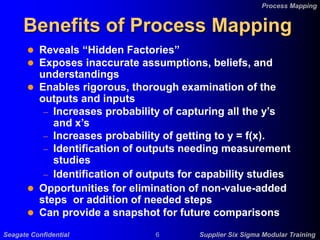

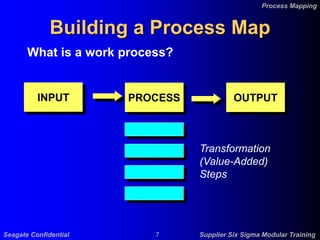

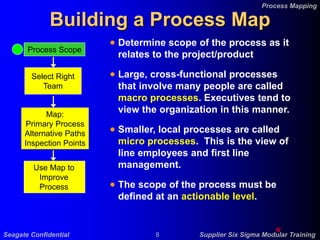

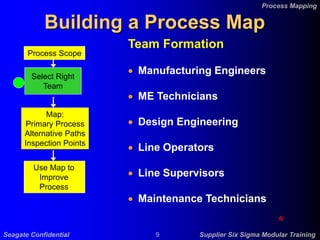

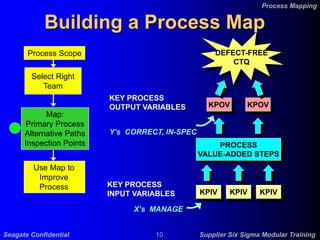

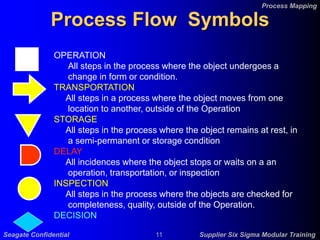

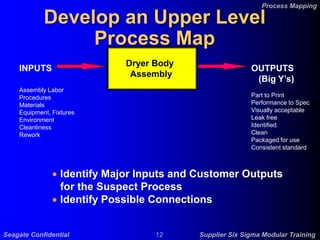

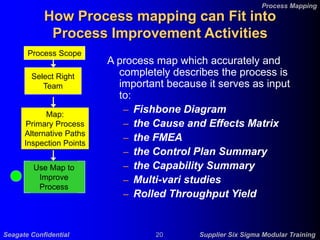

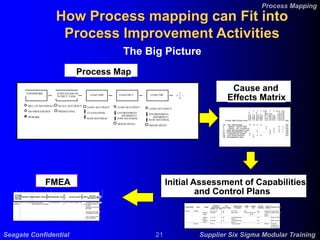

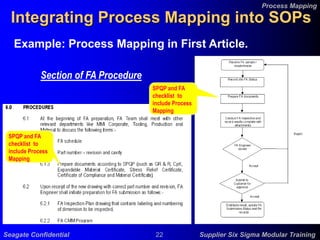

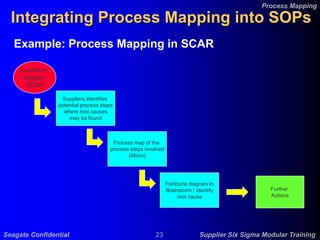

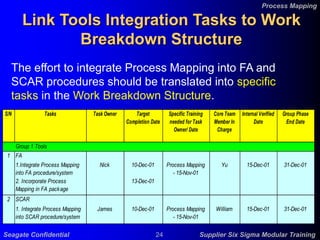

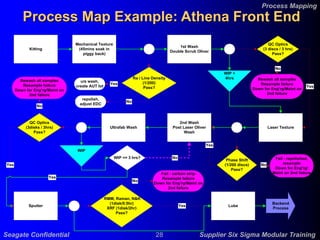

This document provides an overview of process mapping. It defines a process map as a graphical representation of a process's flow that contains information to improve the process. Process mapping reveals hidden aspects of processes and allows for thorough examination. Building an accurate process map is important as it can be used as input for other improvement tools like fishbone diagrams and FMEAs. The document reviews how to scope a process, select a team, map steps and flows, identify inputs and outputs, and integrate process mapping into standard operating procedures.