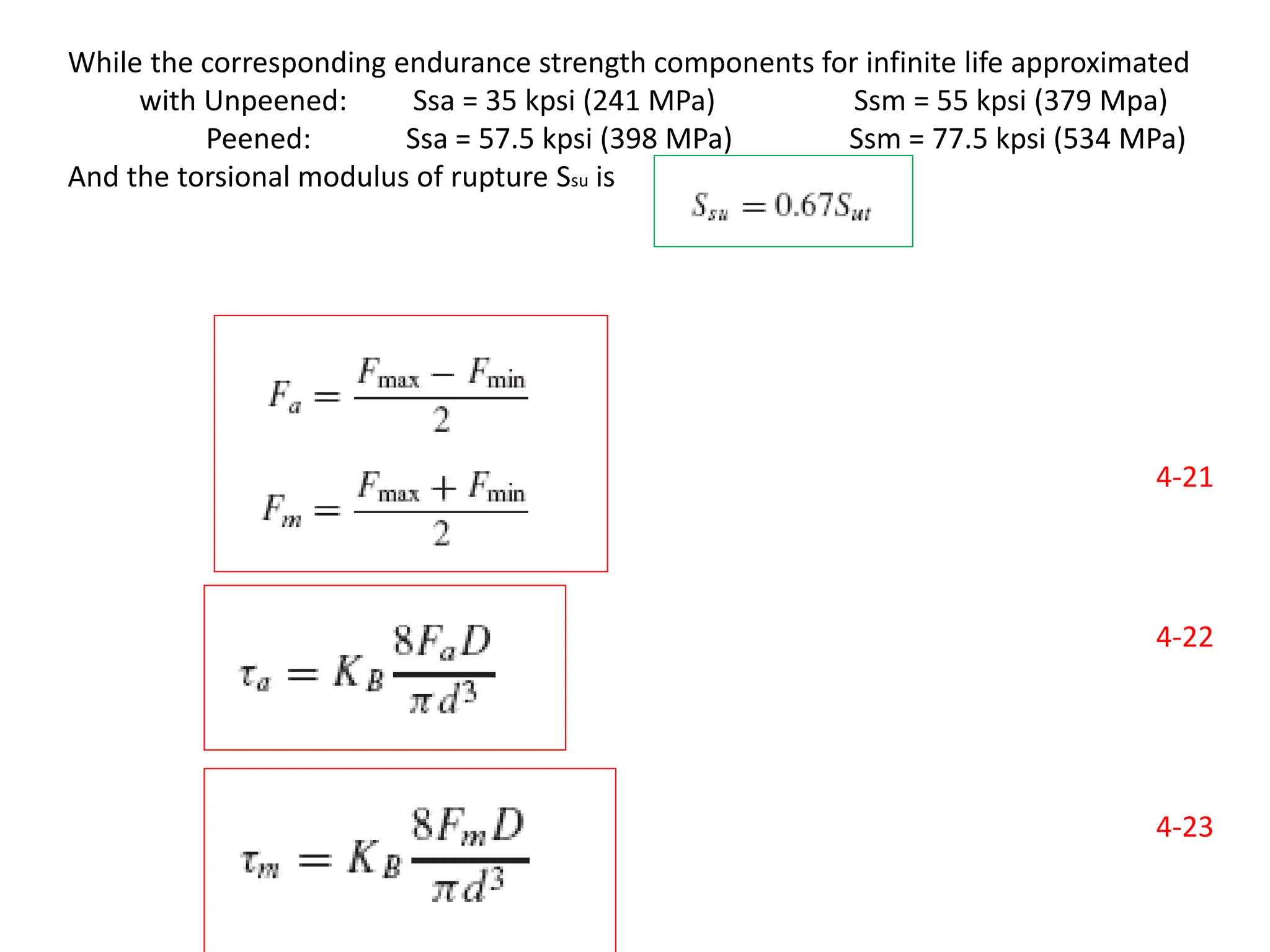

The document discusses different types of mechanical springs, including helical compression springs, helical tension springs, and helical torsion springs. It covers spring materials such as music wire and oil-tempered wire. Key aspects of helical compression spring design discussed include stresses in the spring, deflection calculation using Castigliano's theorem, stability, and fatigue loading. Critical frequency of helical springs is also addressed. The document provides information on tension helical springs and discusses their ends.