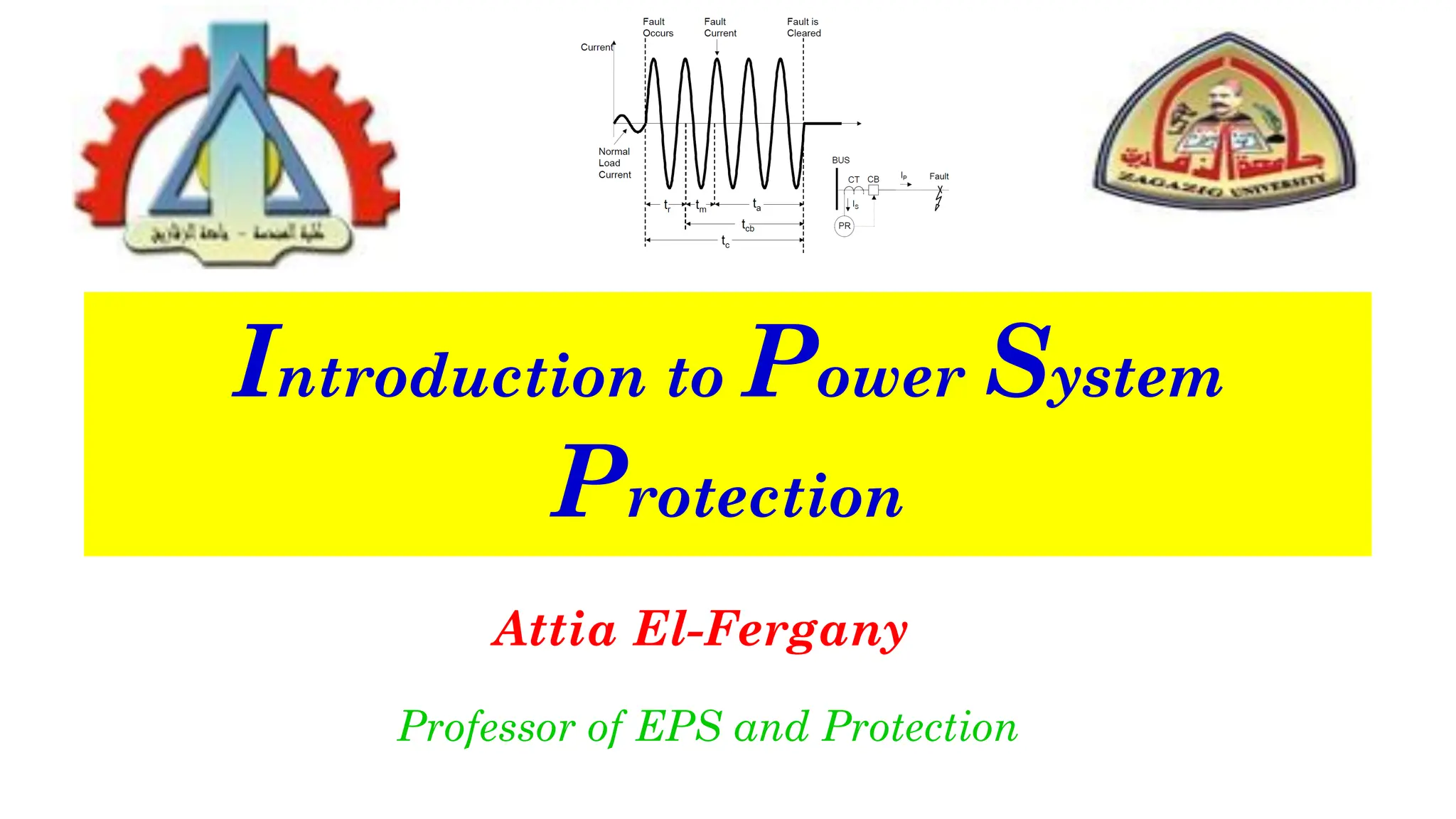

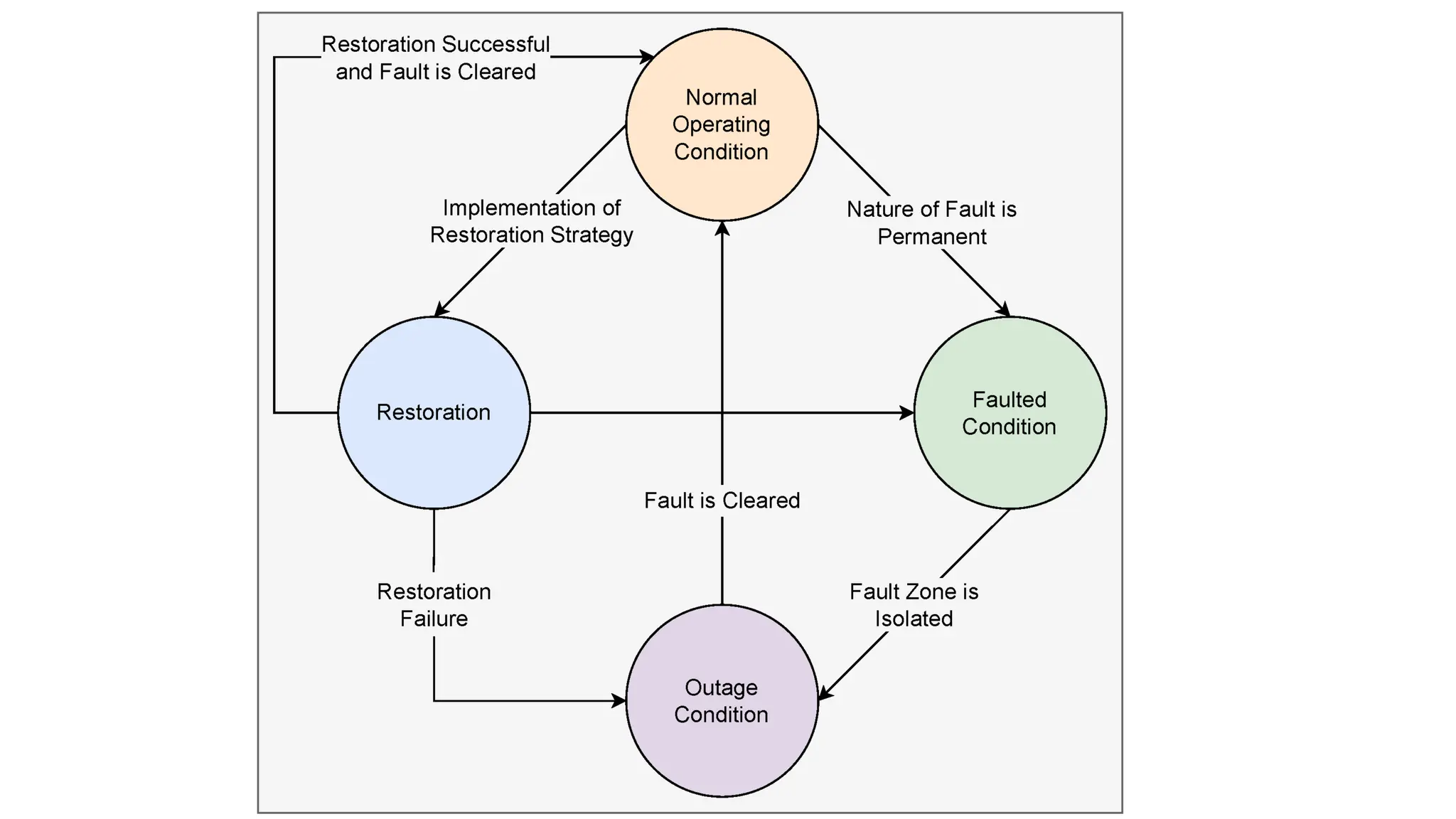

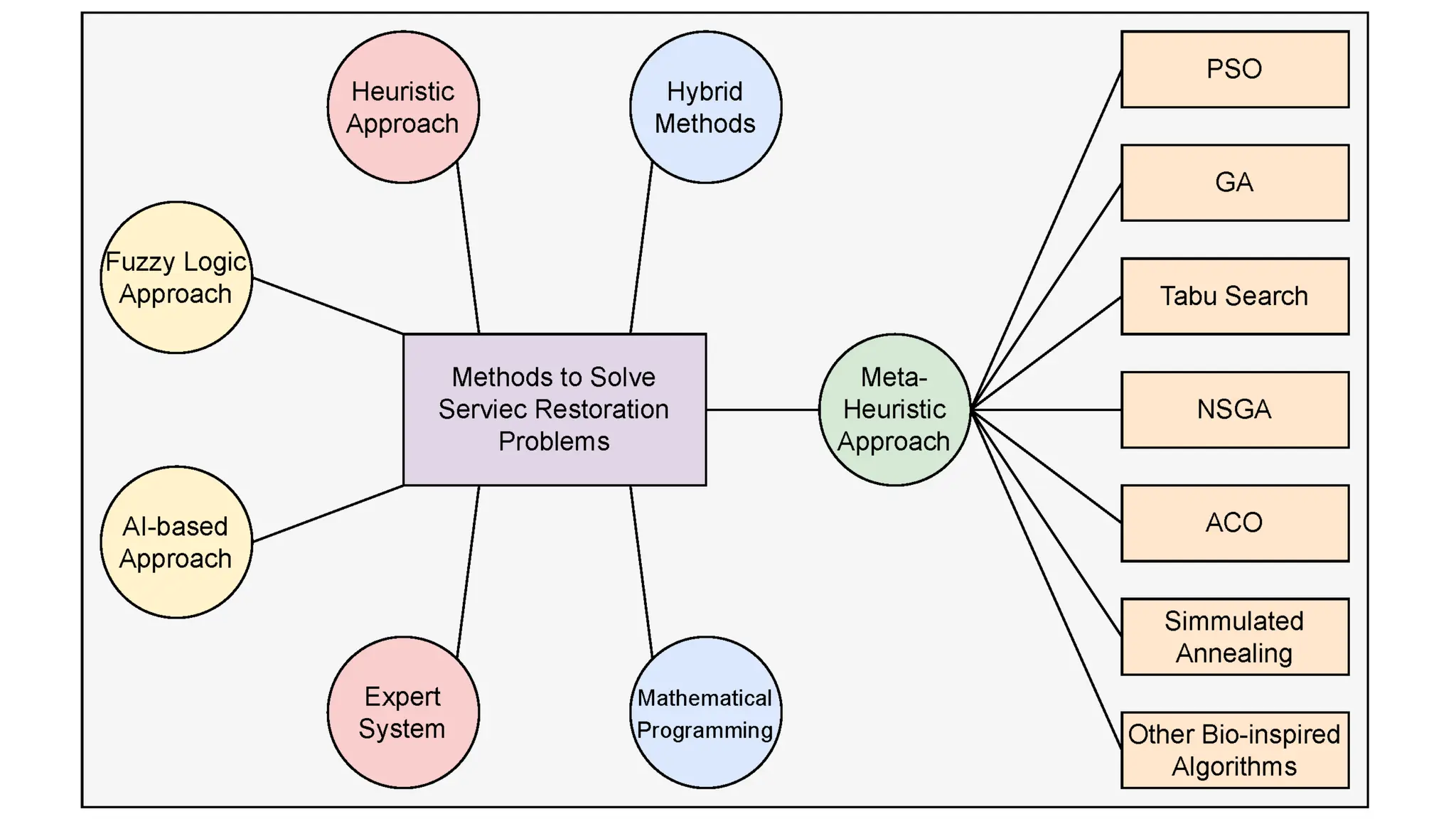

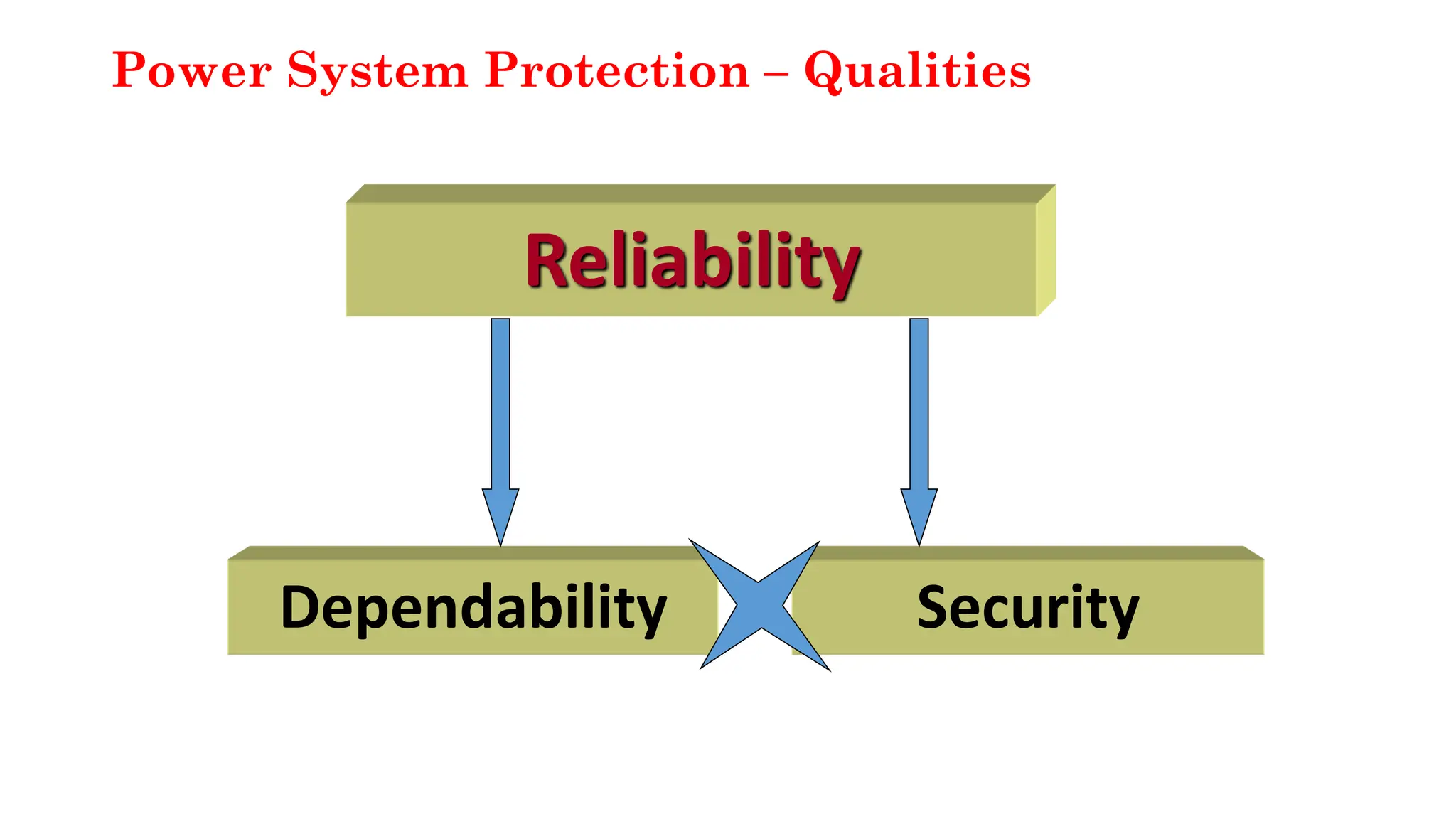

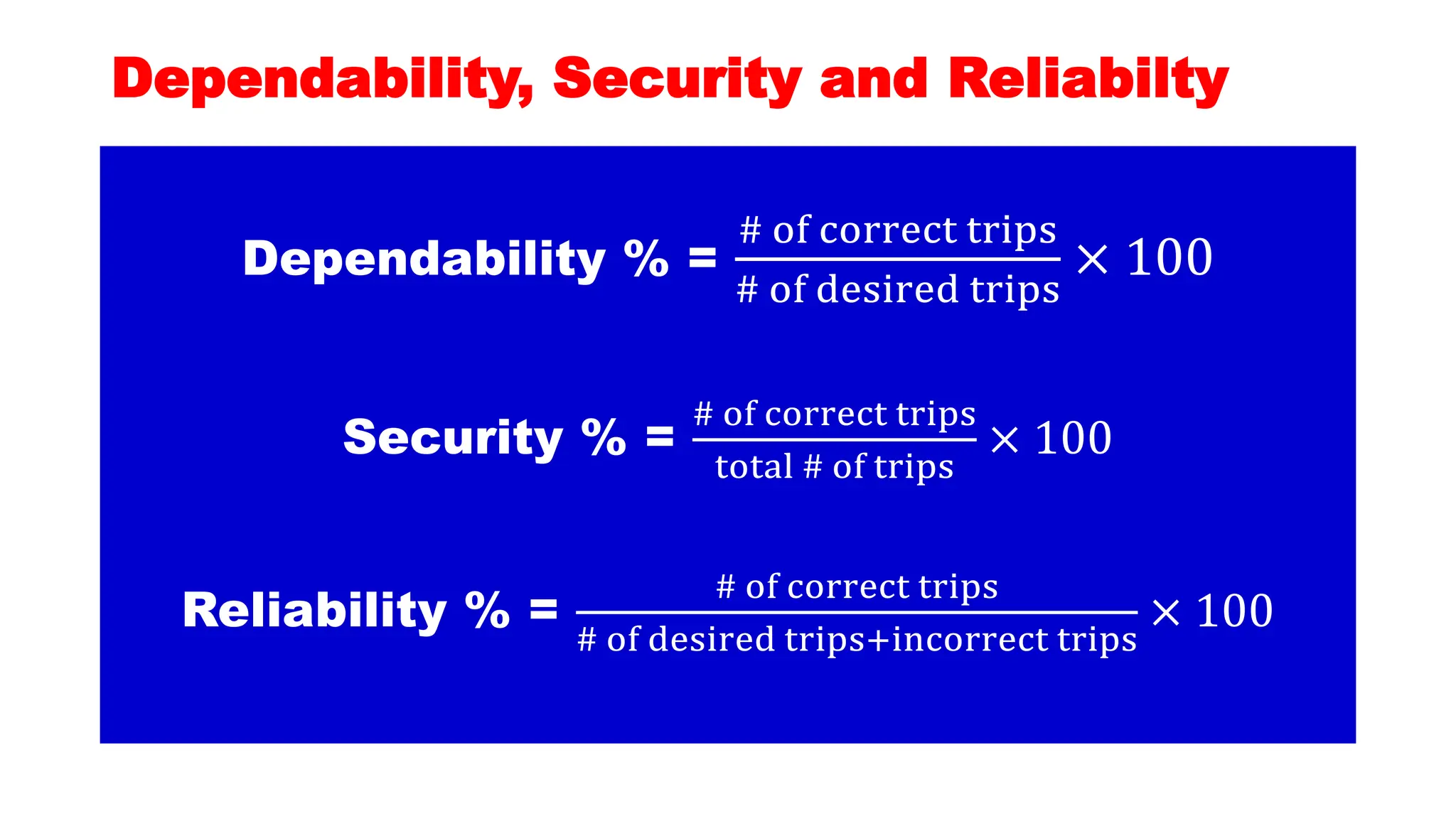

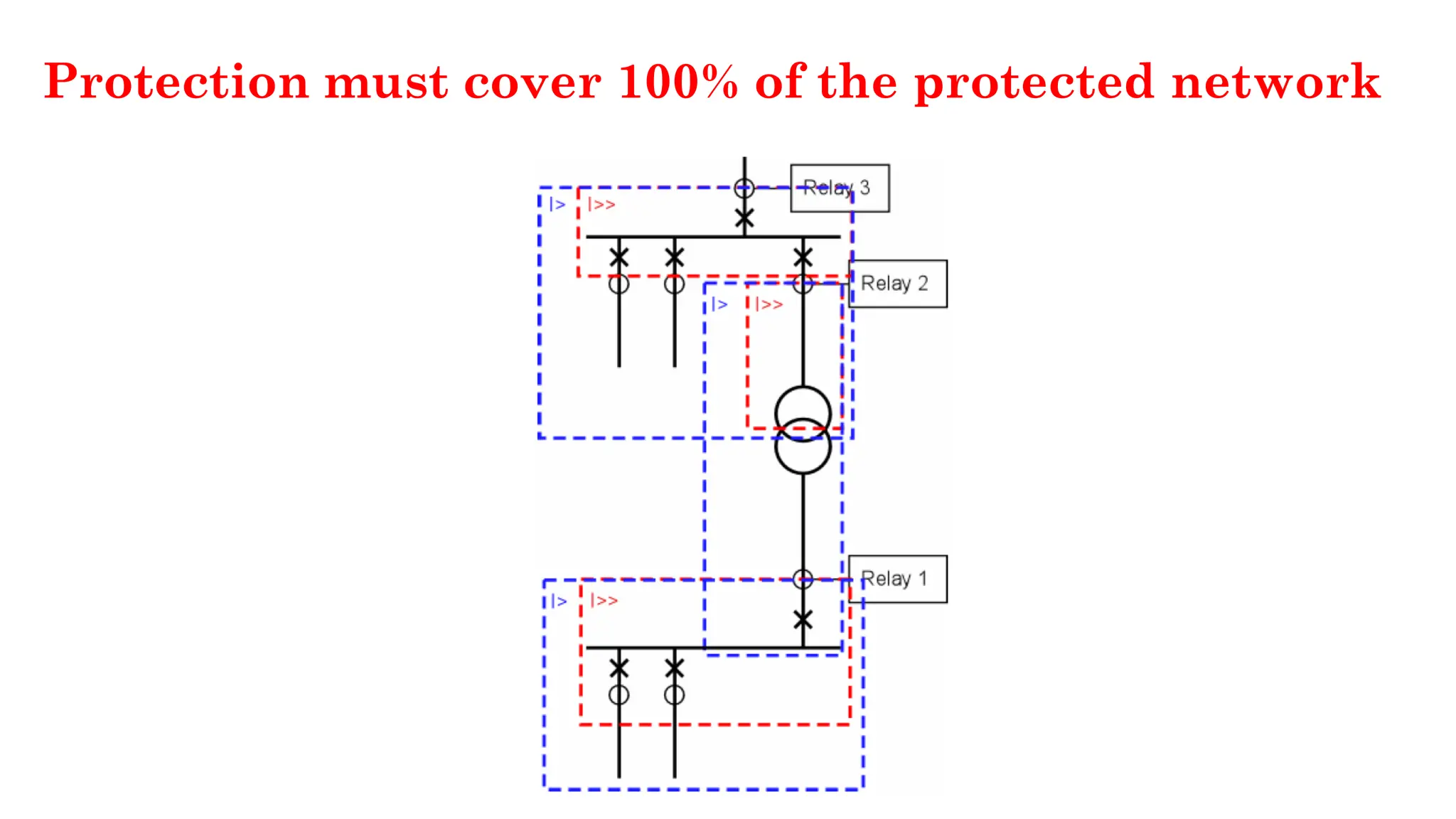

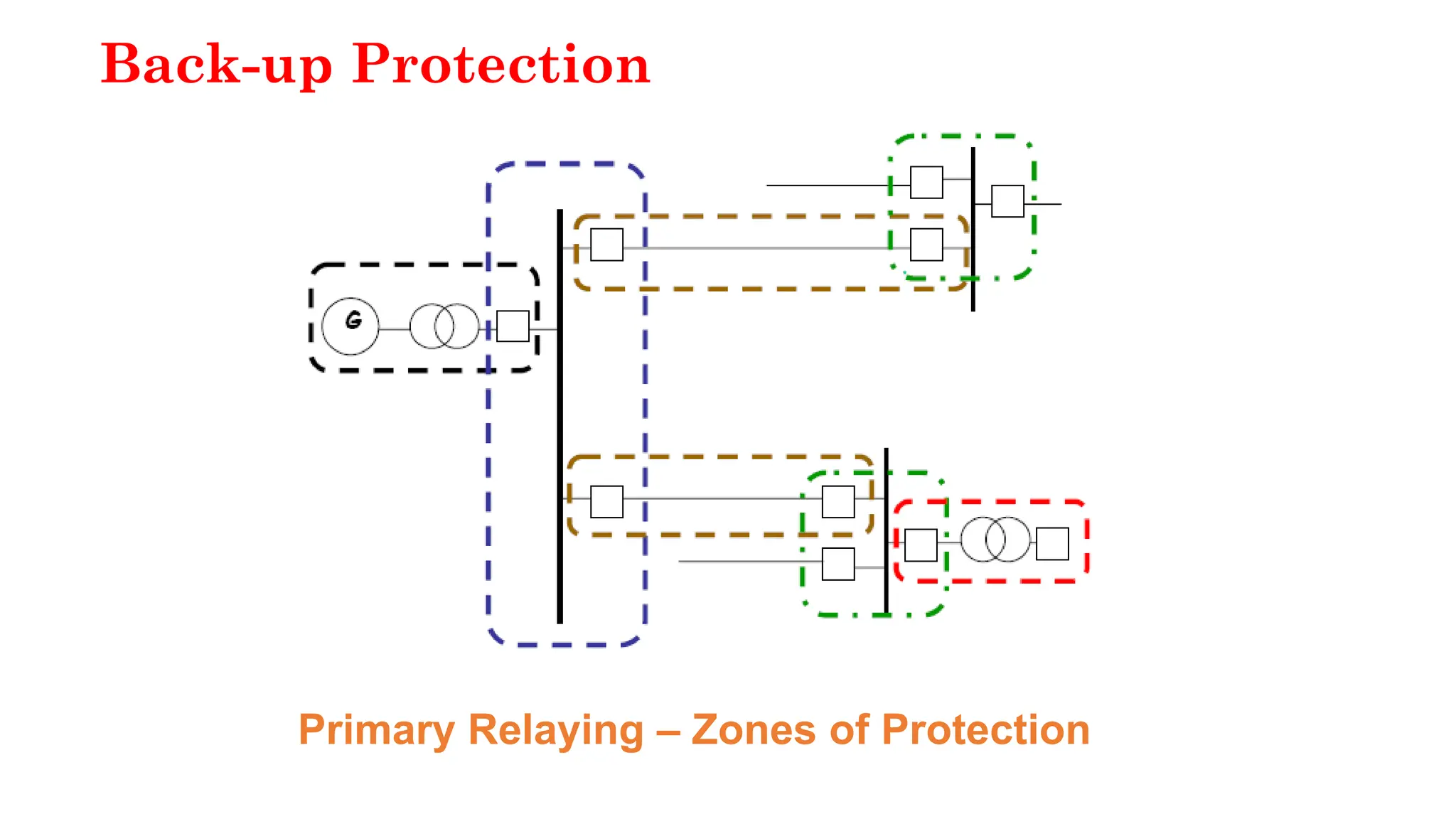

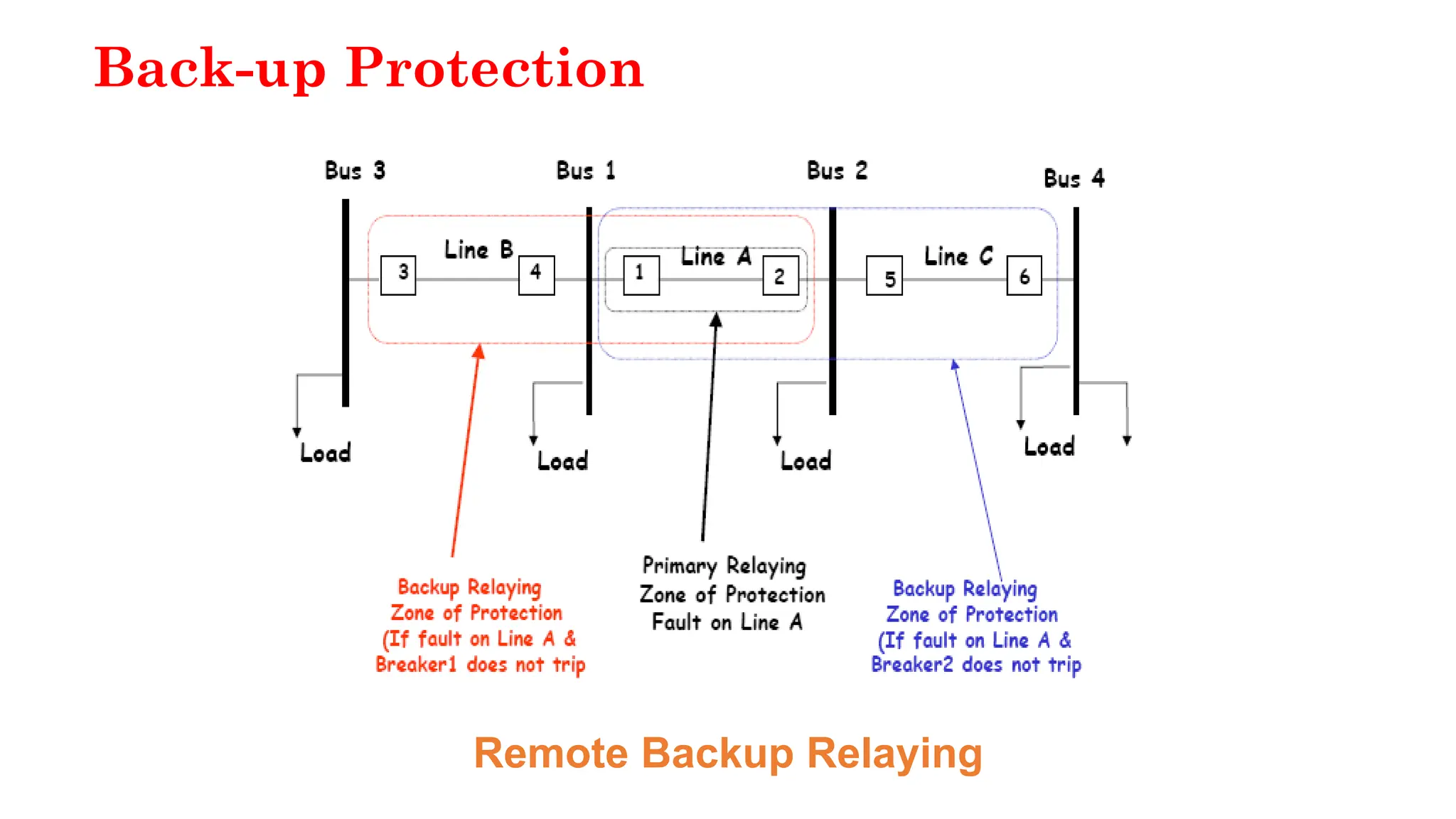

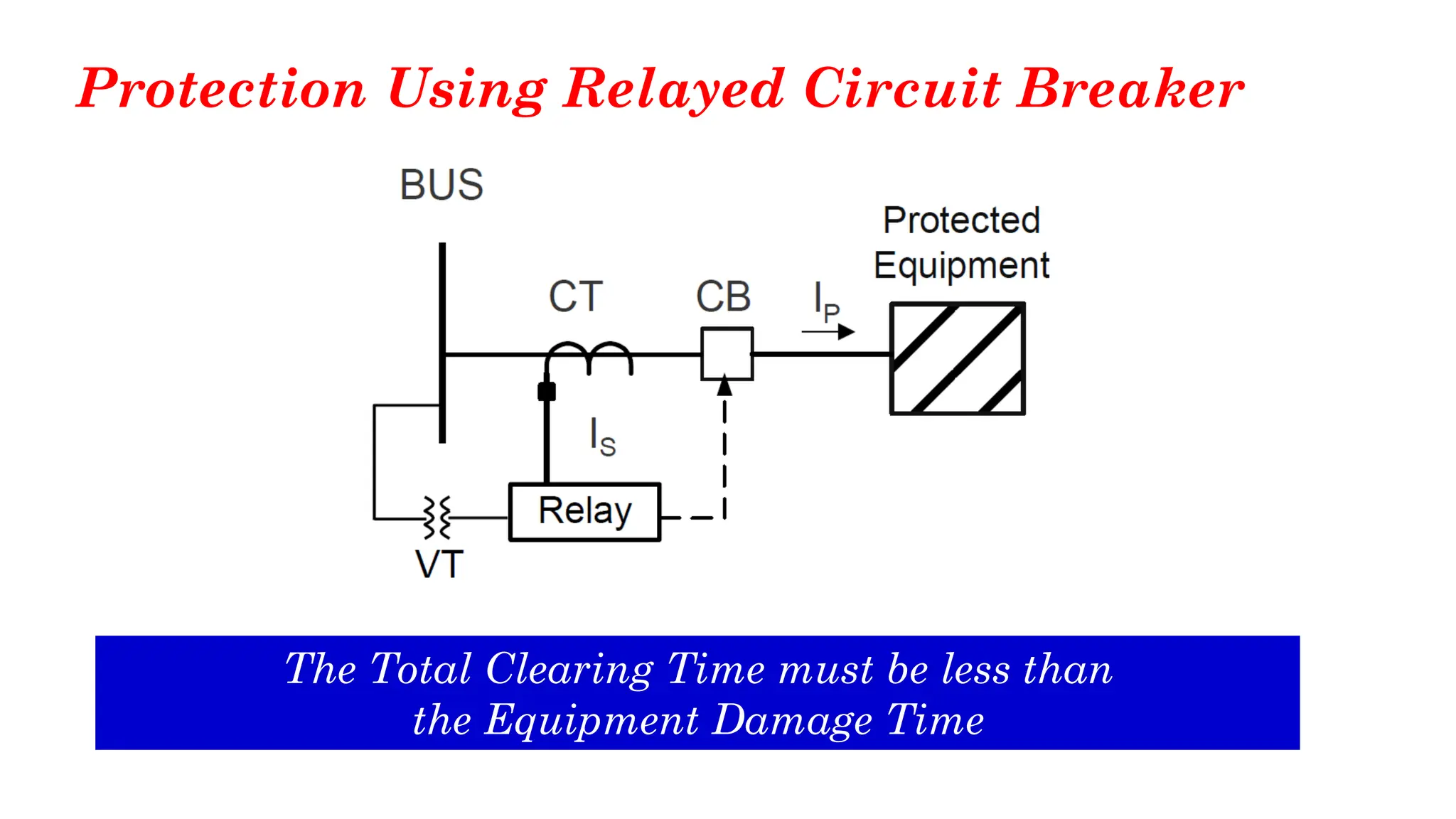

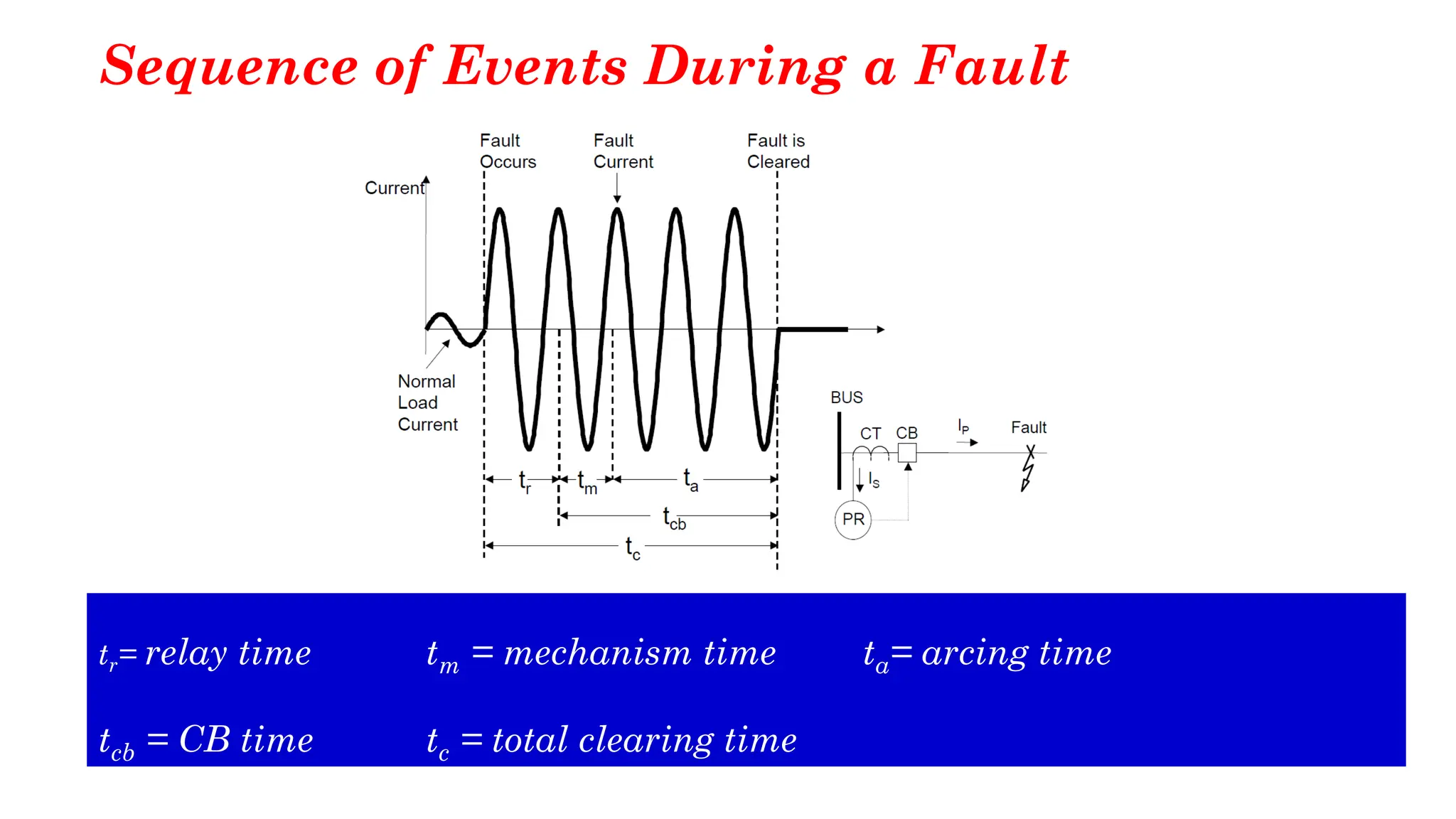

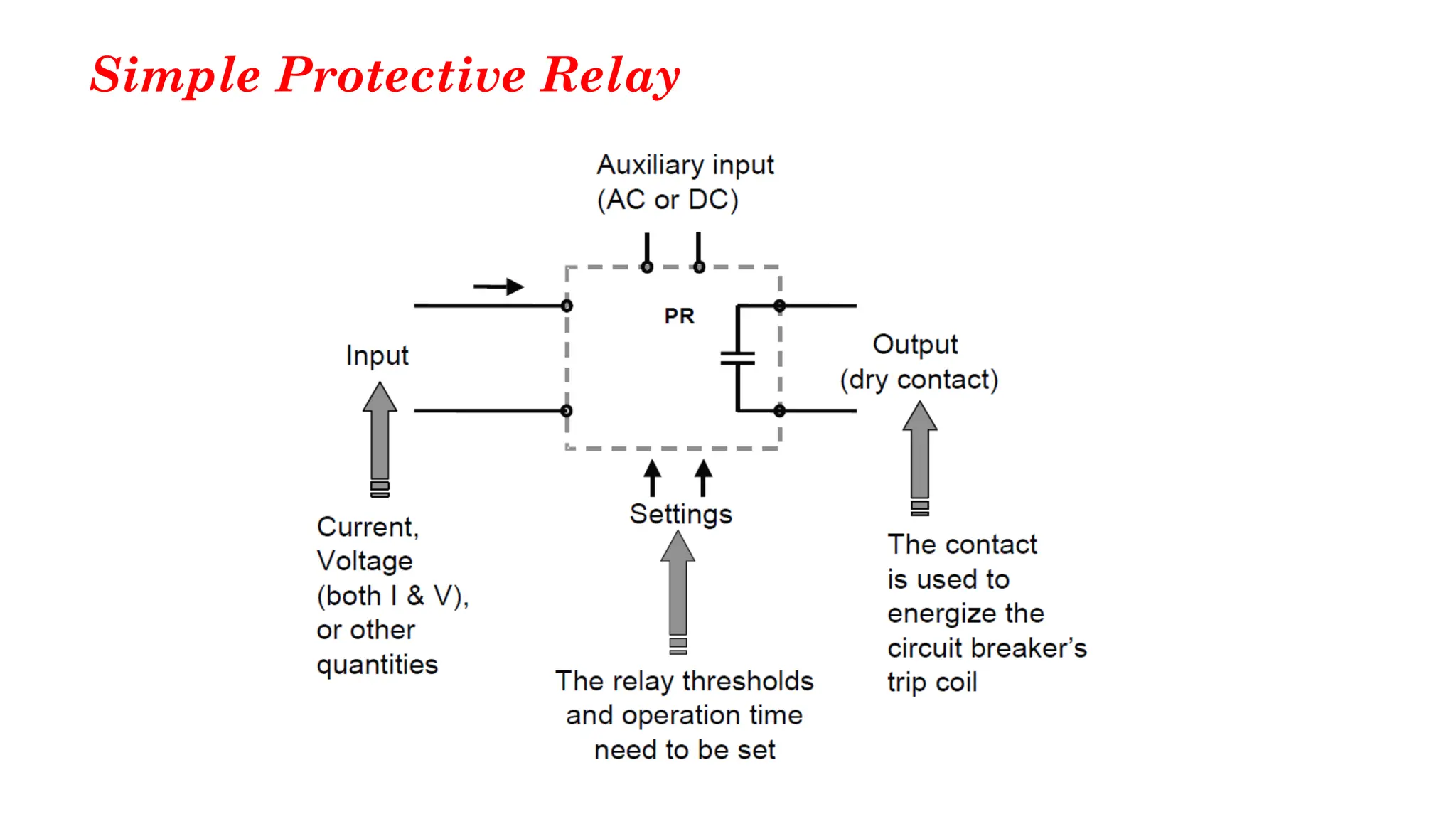

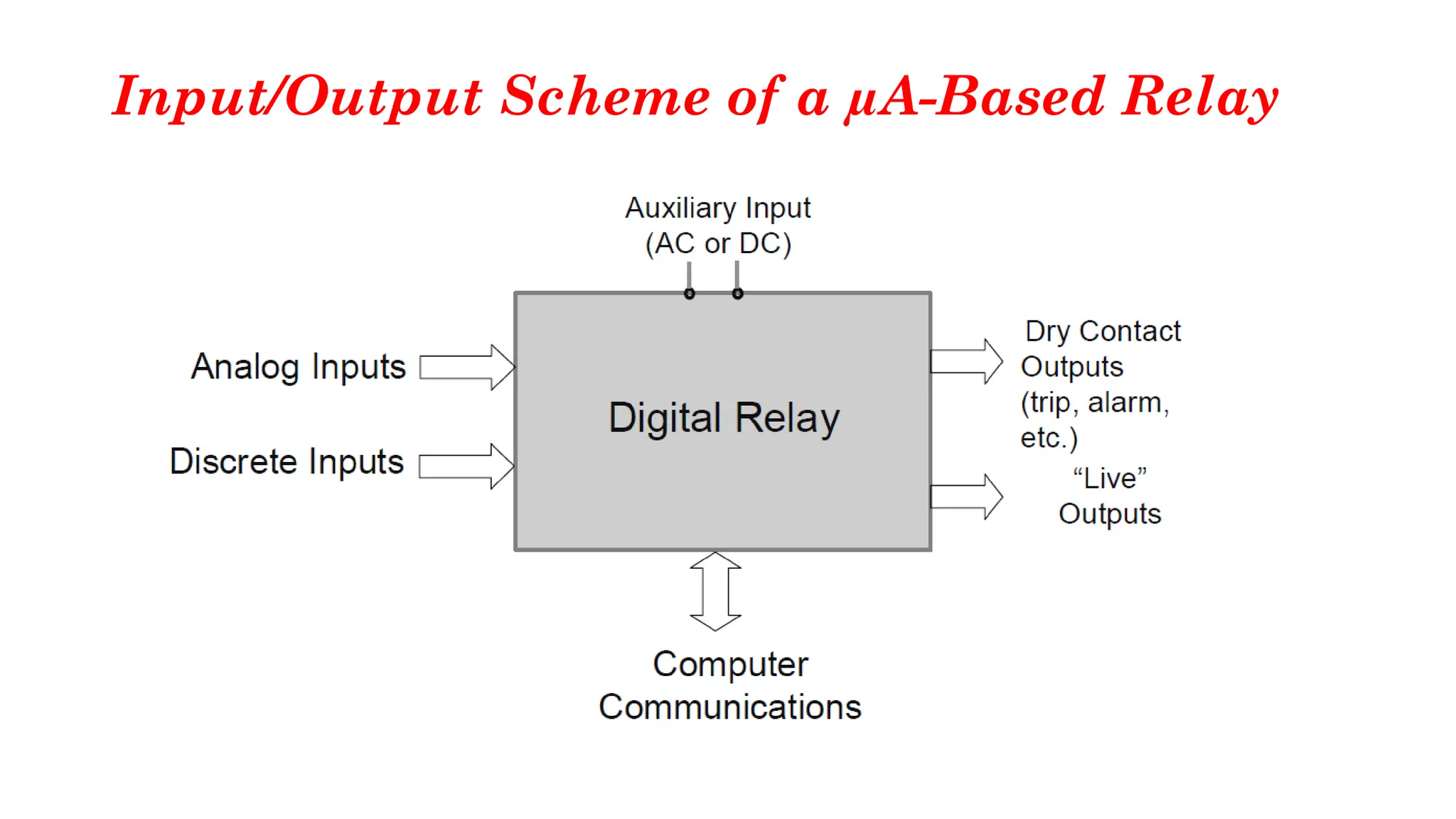

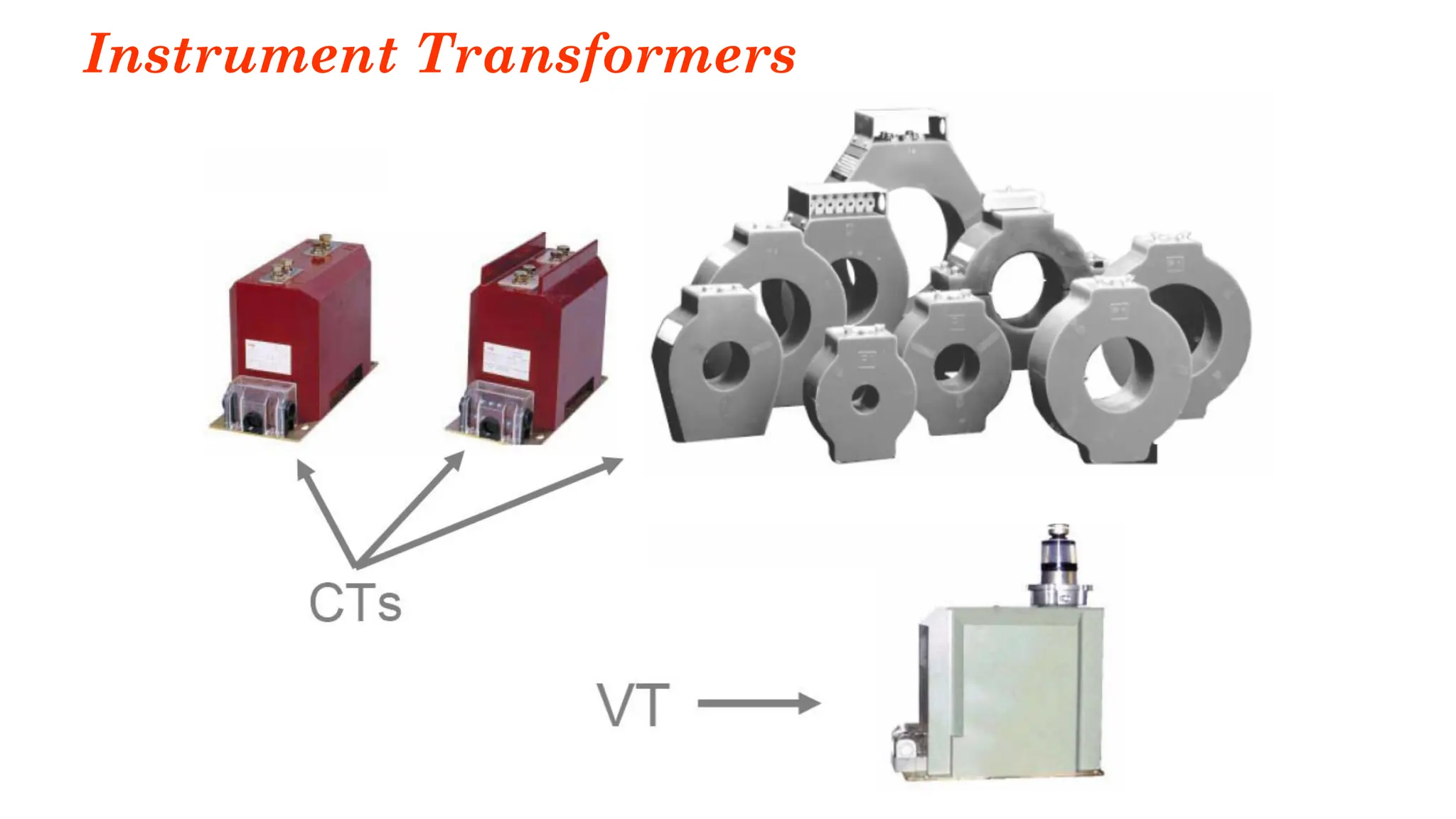

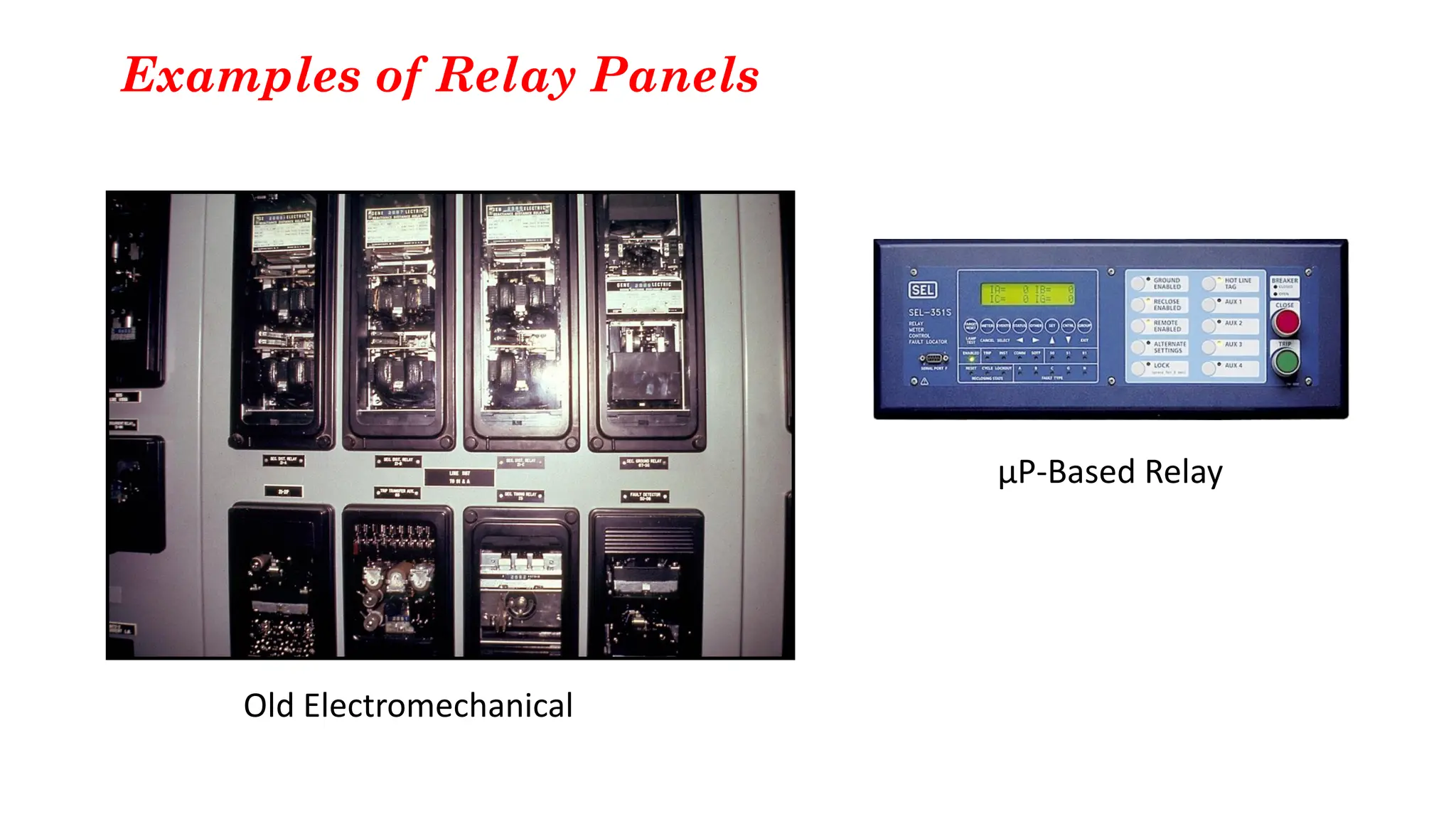

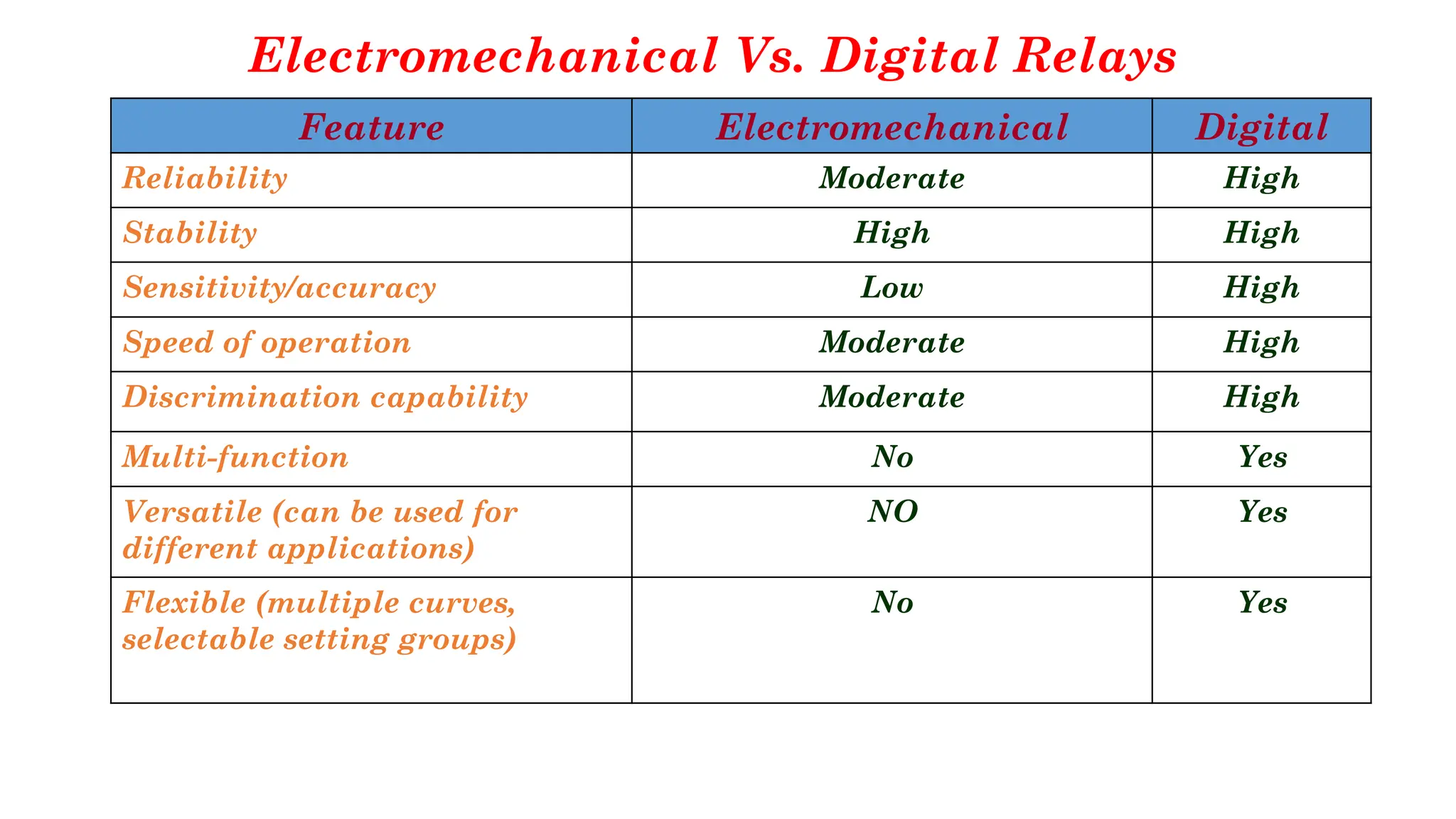

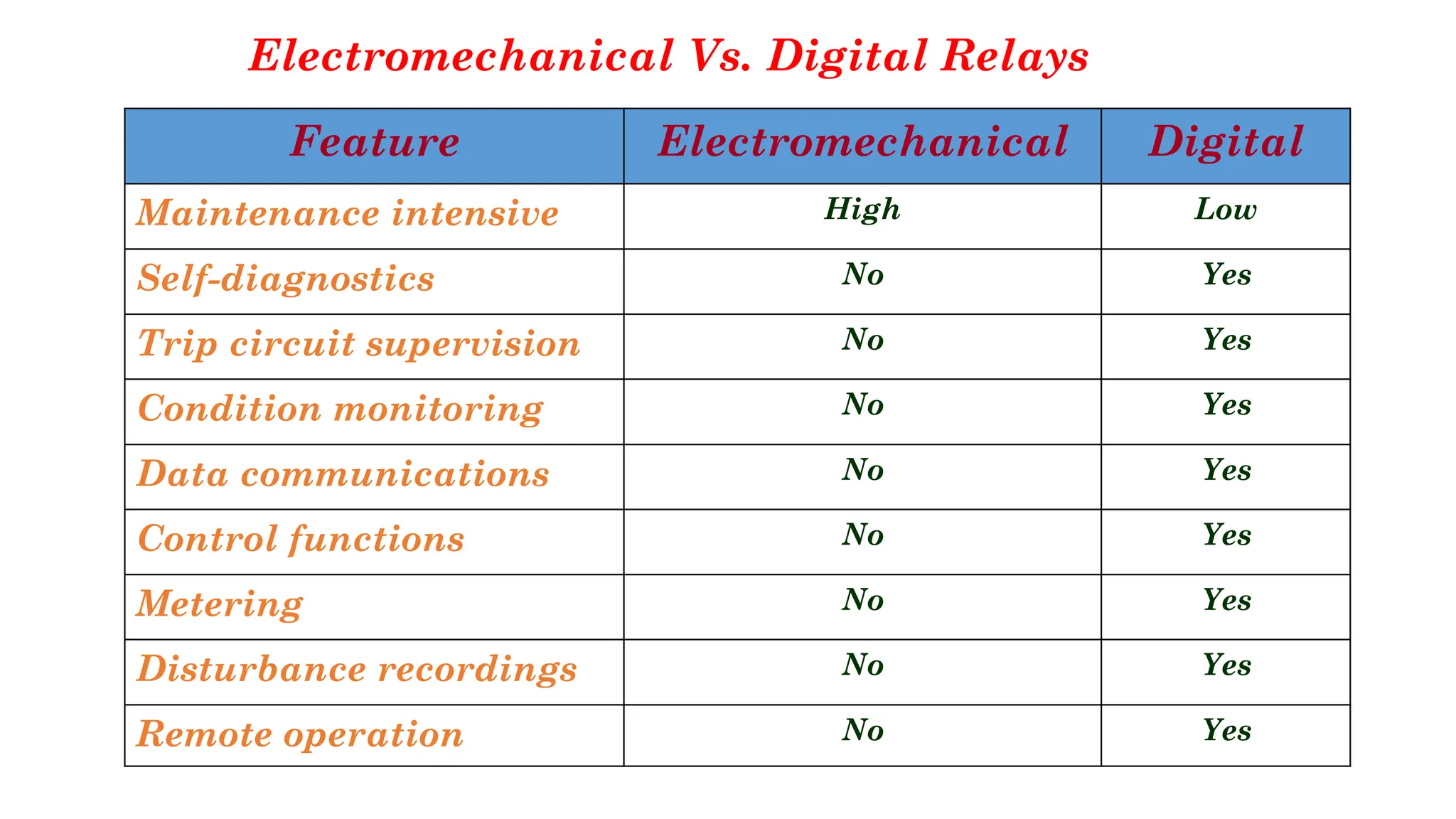

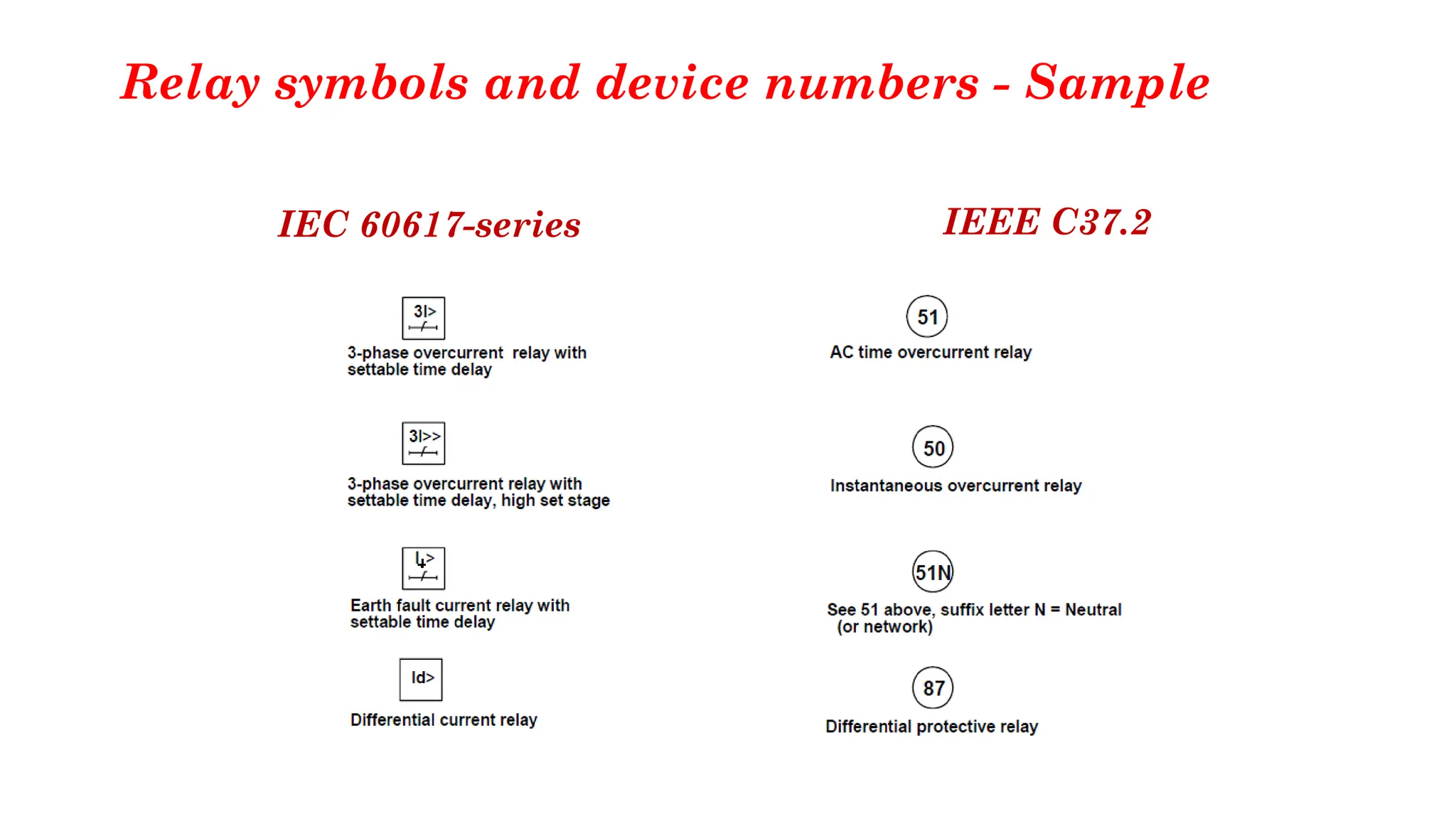

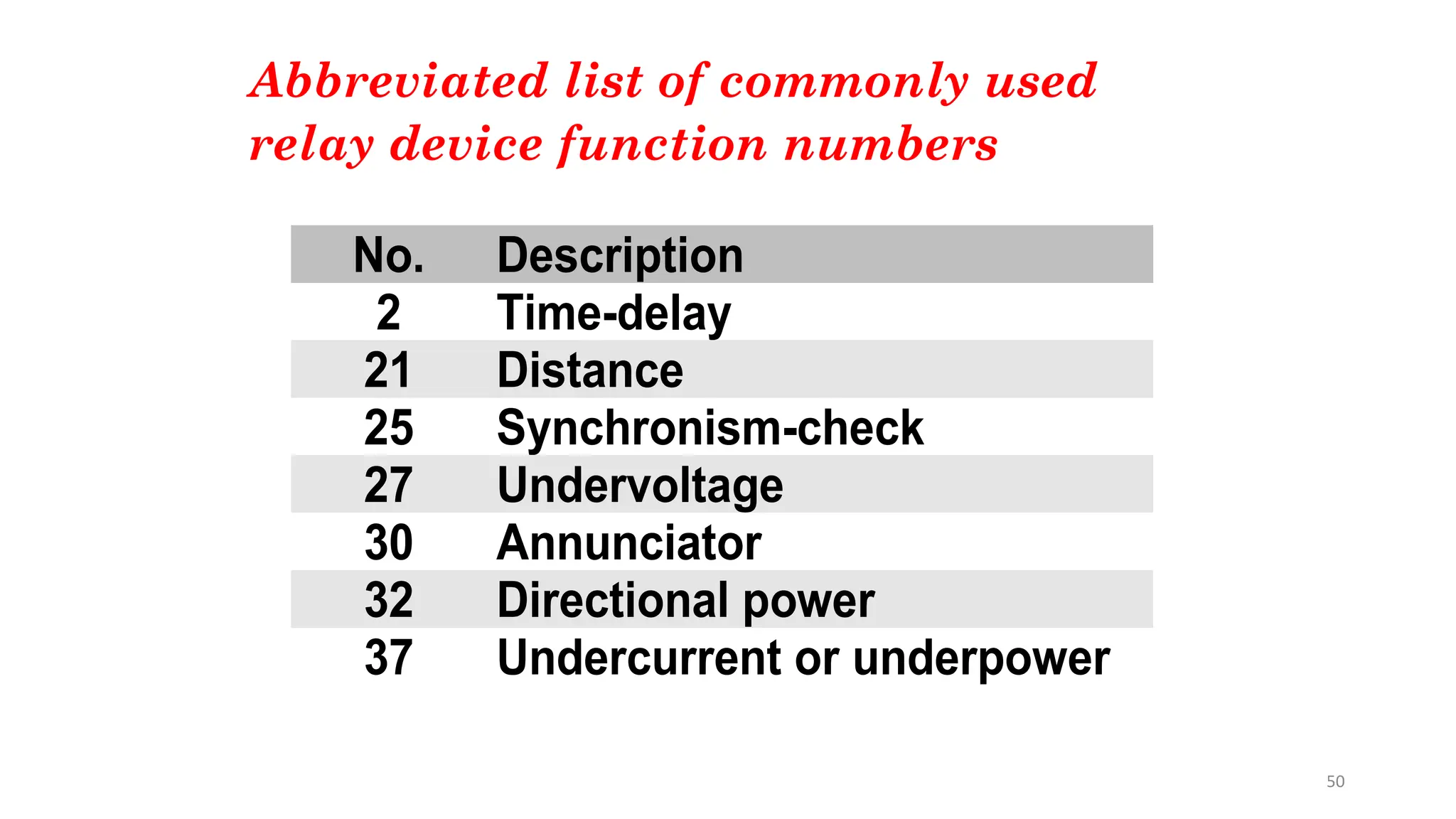

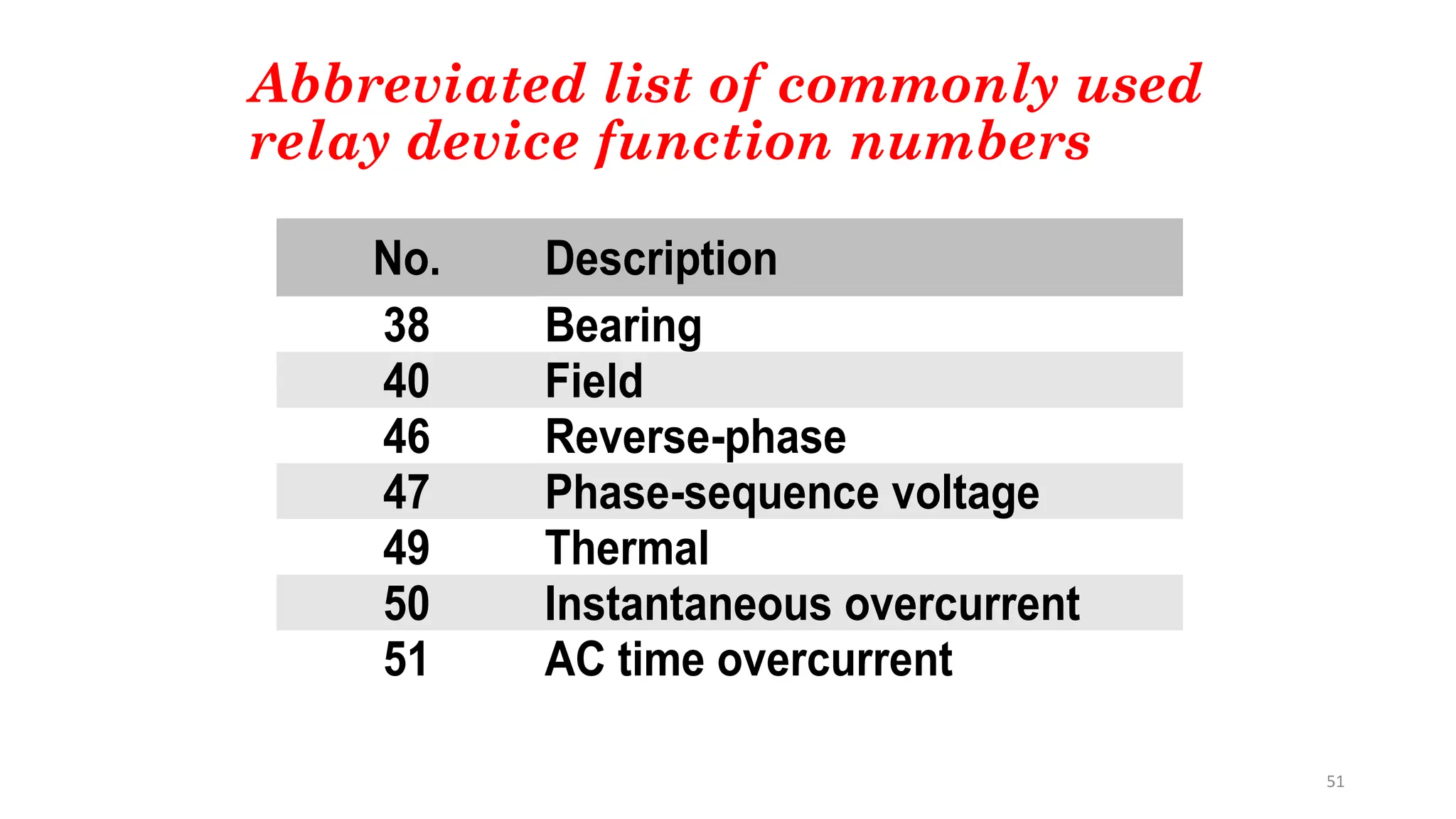

The document outlines the course objectives for power system protection, emphasizing the necessity for protective systems to detect faults, minimize damage, and ensure safety. Key roles of protective relays include equipment failure isolation, system stability enhancement, and overload protection, while good protection schemes must exhibit reliability, selectivity, and speed. It also discusses various types of protection methods, the evolution of relays from electromechanical to digital, and the factors affecting protection system design.