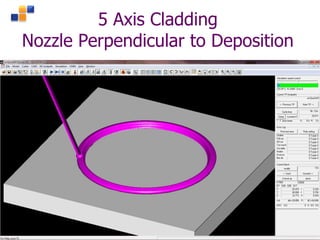

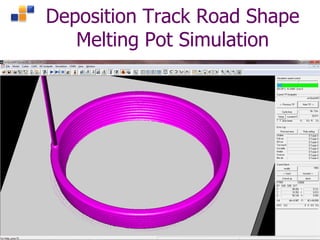

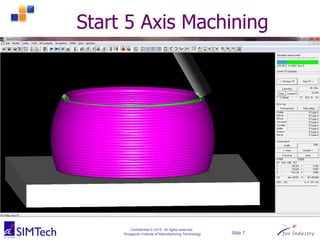

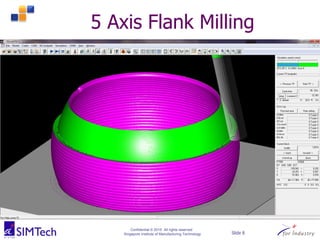

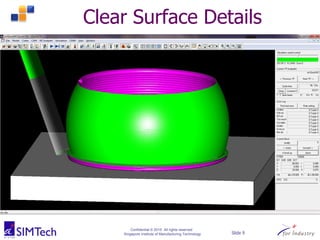

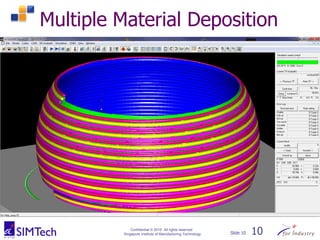

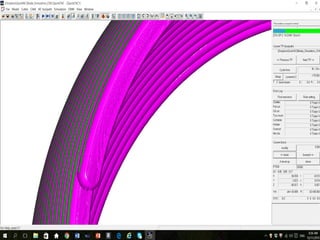

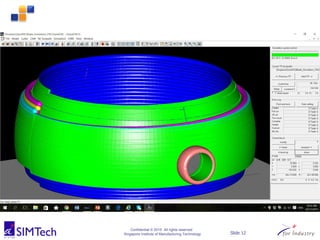

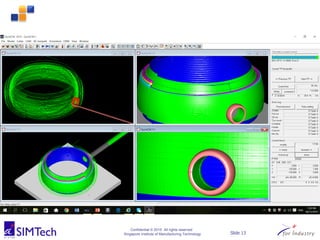

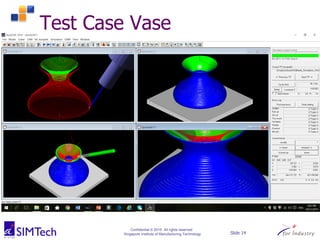

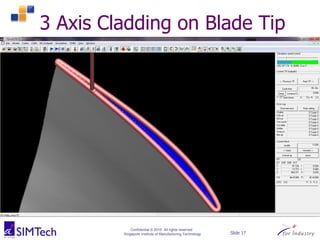

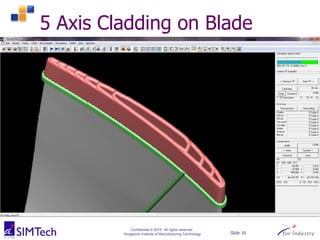

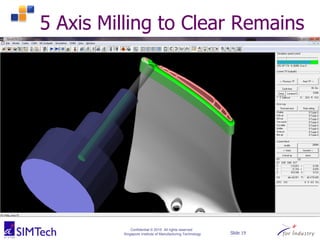

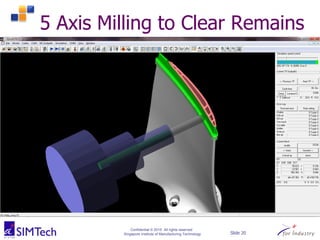

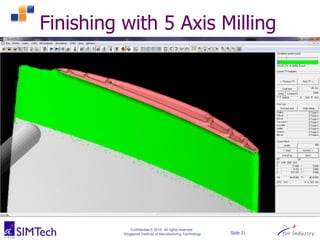

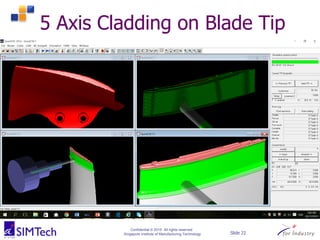

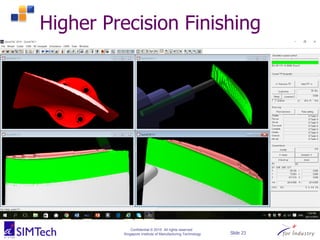

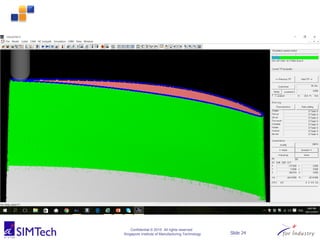

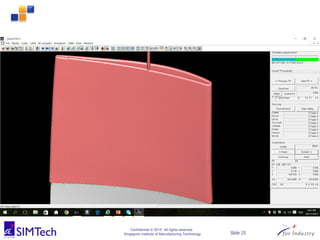

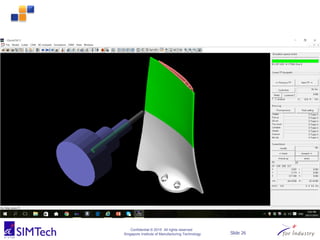

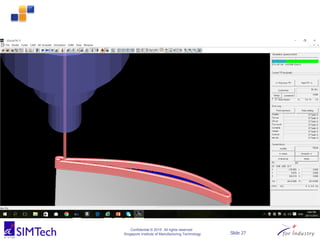

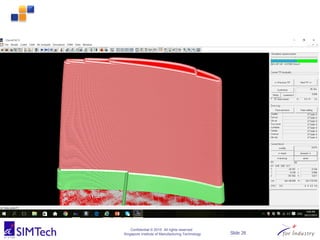

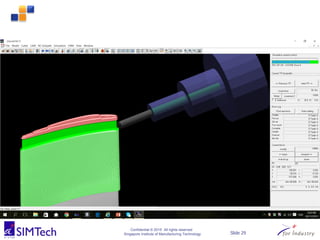

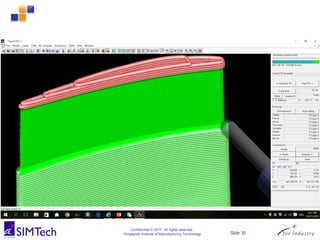

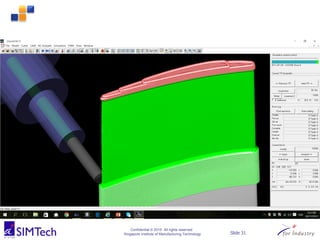

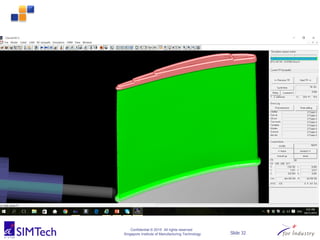

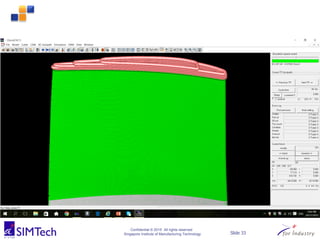

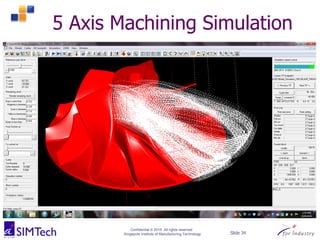

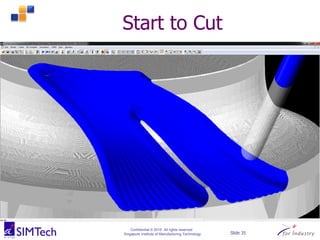

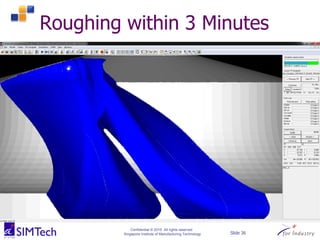

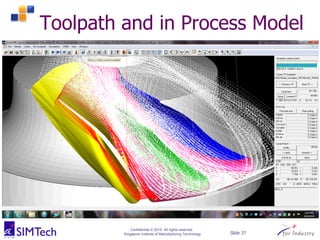

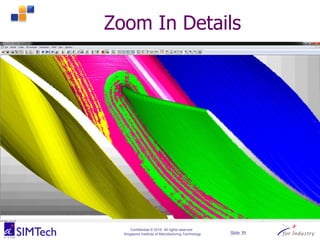

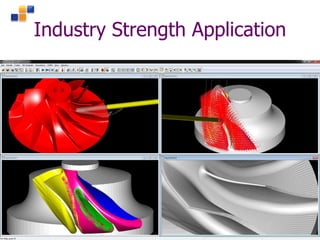

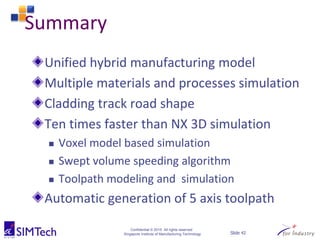

The document discusses a unified model for hybrid manufacturing that combines subtractive and additive processes, addressing the growing demand for effective simulation in this area. It highlights various manufacturing techniques, including 3-5 axis machining and multiple material deposition, and showcases the efficiency of their simulation methods, which are significantly faster than traditional systems. Key features include automatic toolpath generation and advanced modeling techniques for precision manufacturing applications.