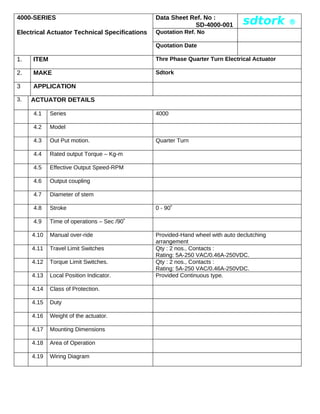

The document provides technical specifications for an electrical actuator. It includes details about the actuator such as its series, model, output motion, torque rating, speed, manual override function, limit switches, position indicator, protection class, duty, weight, mounting dimensions, area of operation, and wiring diagram. It also provides specifications for the motor including its type, supply voltage, duty, insulation class, and rating. Optional accessories are listed along with general points about the scope of supply, inspection, manuals, warranty, and painting.