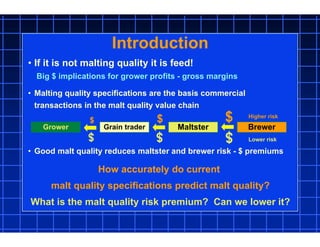

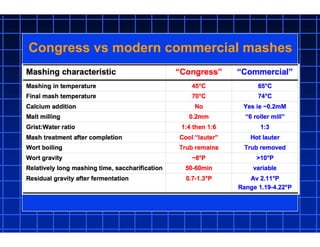

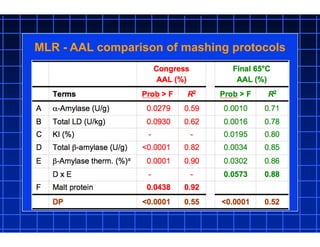

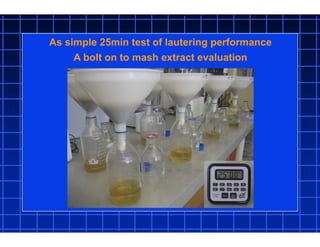

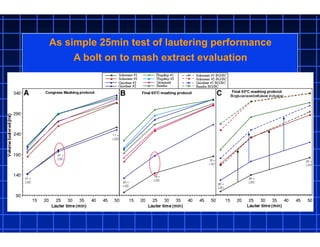

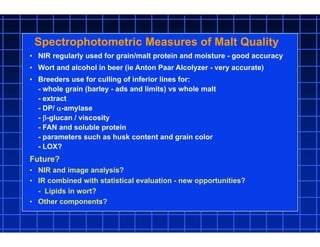

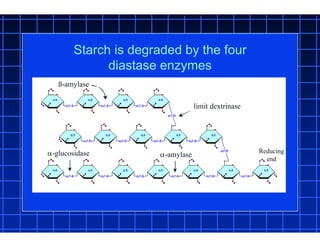

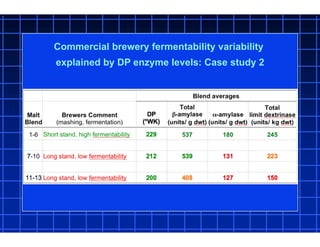

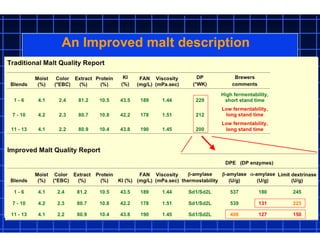

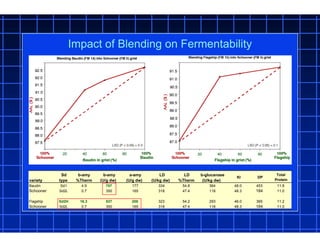

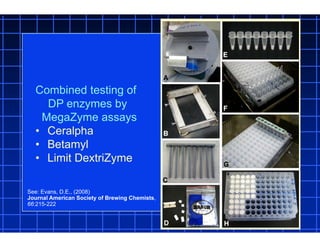

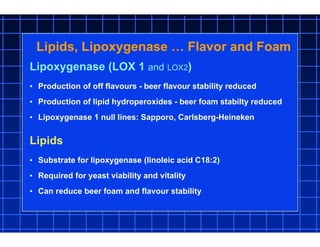

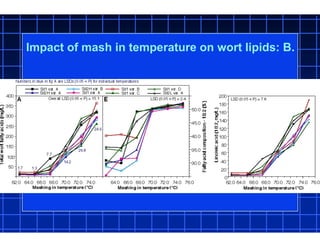

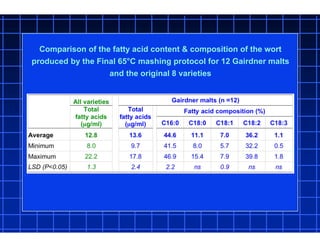

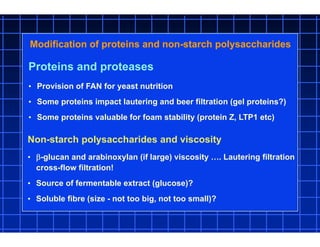

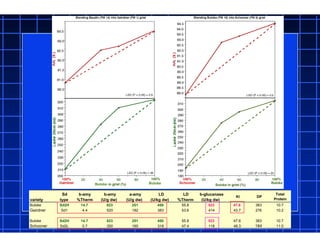

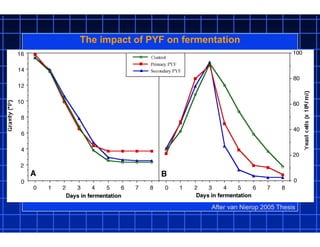

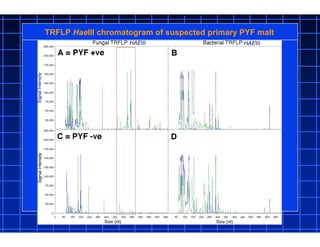

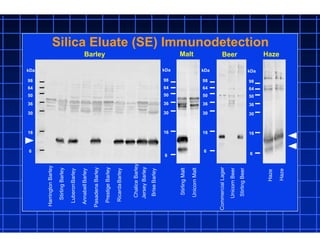

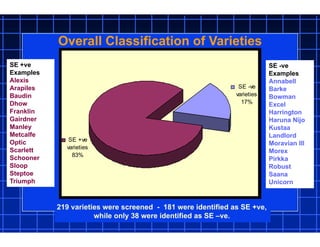

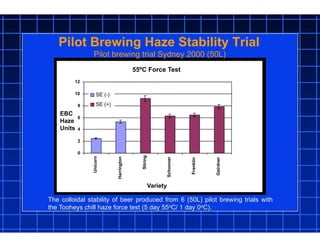

Modernization of malt quality analysis to better inform brewers, maltsters and barley breeders. This document discusses functional tests and future opportunities to improve malt quality specifications. It summarizes several key areas for improvement, including mashing procedures, mash filtration performance, spectrophotometric measures, DP enzymes, protein and polysaccharide modification, lipids and flavor, microbial assessment, beer clarity, and the goals and targets of brewers, maltsters, and barley breeders. The overall goal is to develop malt quality specifications that are more accurate, rapid and cost efficient.