This document summarizes a student project that models the suspension system of a luxury automobile. The project aims to determine optimal parameters for springs, dampers, tires and masses to meet ride quality requirements. The model simulates two scenarios: 1) hitting a 3-inch bump at 25 mph and 2) traveling on bumpy terrain at 25 mph with 1-inch bumps spaced 1 foot apart. The results show that with the right component parameters, the requirements can be met. Parameters recommended are a 3000 kg body mass, 200 kg unsprung mass, 8 million N/m spring rate and 700,000 N*s/m damper constant.

![The following equation is related to ẍ1, the displacement of the

car’s body:

𝑥̈1 =

𝑘1 𝑥2 − 𝑘1 𝑥1 + 𝑐𝑥̇2 − 𝑐𝑥̇1

𝑚1

where 𝑘1 is the spring rate, 𝑥1 is the displacement of the

vehicle body, 𝑥2 is the movement of the tire, 𝑐 is the damping

constant ofthe shockabsorbers, 𝑥̇1 is the velocity of the car

body,and 𝑥̇2 is the velocity of the unsprung mass.

The equation for ẍ2, the acceleration of the unsprung

mass is:

𝑥̈2 =

𝑘2 𝑦 − 𝑘2 𝑥2 + 𝑘1 𝑥2 − 𝑐1 𝑥̇2 + 𝑐1 𝑥̇1

𝑚2

where y is the input force provided by the road in the form of

surface irregularities or bumps.

III. RESULTS

A. Tables and Figures

All tables and figures are included in the appendix to allow for

easier viewing. Please see refer to page 3 or section IV.

B. Analysis

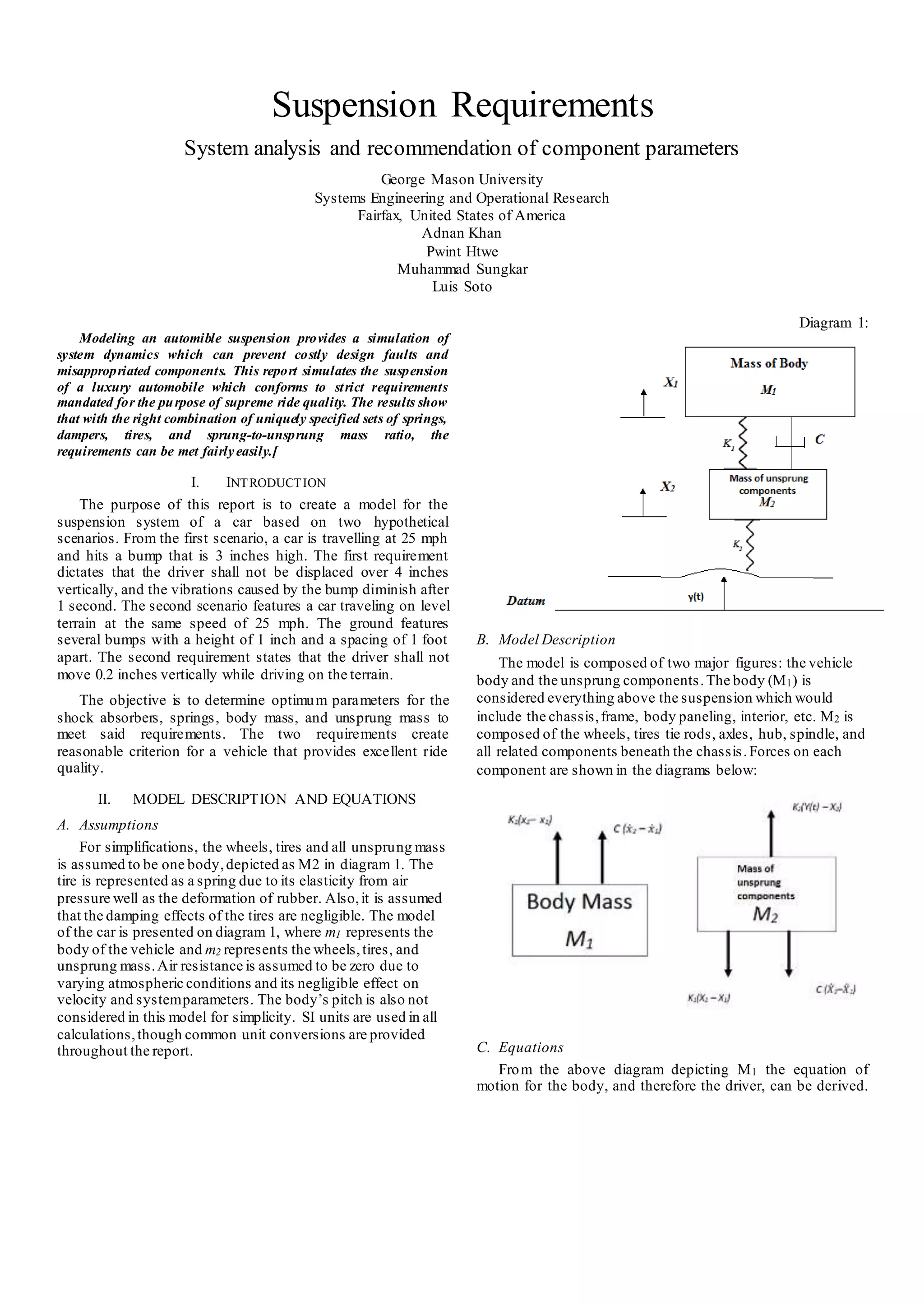

For the first scenario, the depicted graph (Appendix: graph

1) shows that the 0.076 meter (~3 inch) bump does not displace

the body more than approximately 0.05 meters, or 2 inches.

This value is well within the maximum allowable vertical

displacement of the driver, which is 4 inches.The shock

absorbers do well to reduce oscillation which is evident by the

systemstabilizing before the one-second mark on the x-axis,

meeting the requirement. However, the configuration may

prove to be too stiff; as the quick downward displacement of

the rigid body may prove to be uncomfortable for drivers. A

different shockand spring constant combination can likely

provide smoother transitions as the vehicle hits the bump and

clears it. The result also suggests that the two requirements

may not be a sufficient measure of ride quality.

From the graph 1 in the appendix, it appears that the input

force has a height of 4 inches and gradually decreases untilit

becomes a horizontal line. This result is plausible because the

amplitude corresponds to the displacement of the vertical. The

sine wave reaches a height of 0 on the one second mark, as

expected.

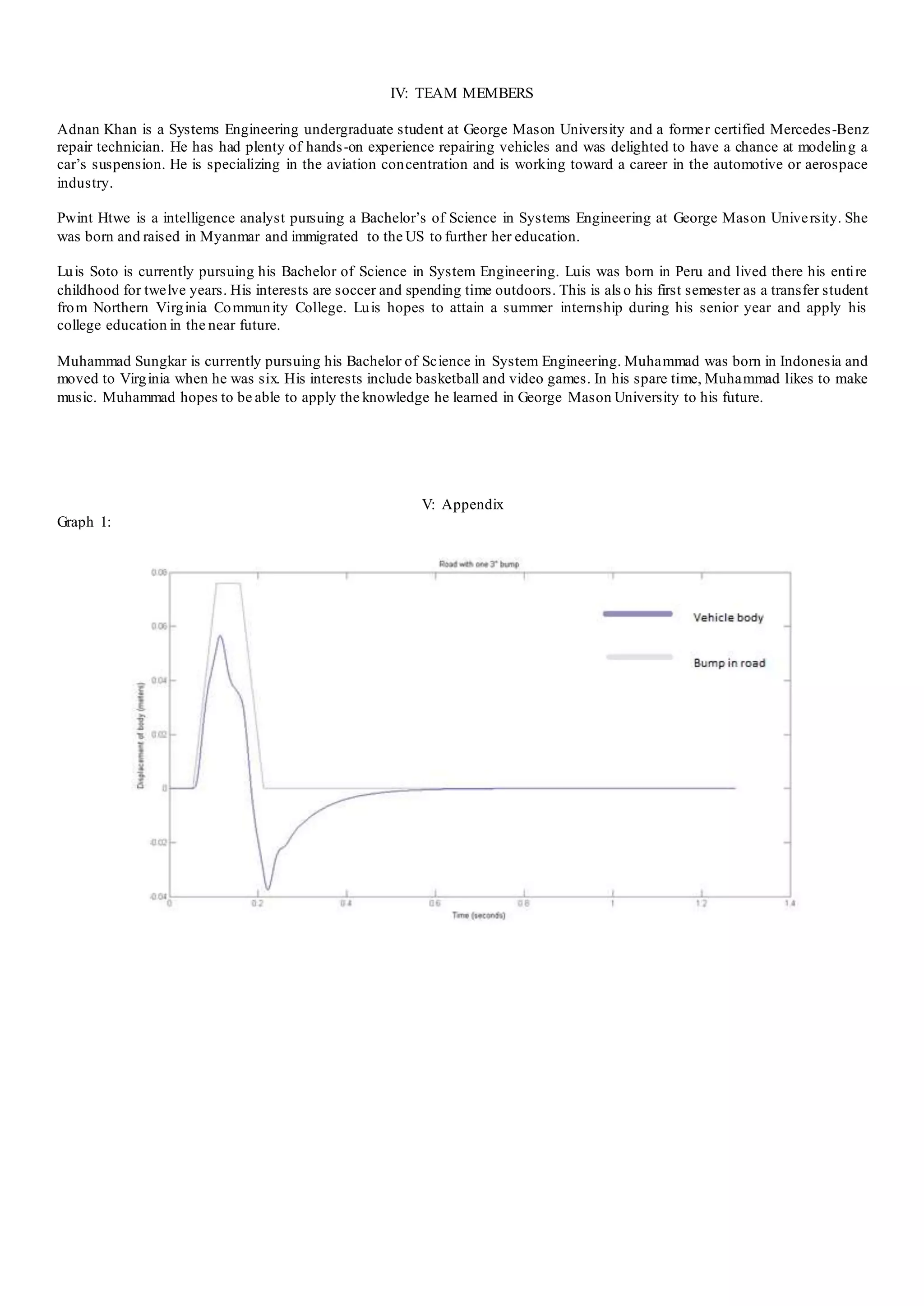

In the second scenario,the output graph (graph 2) is an

oscillating sine wave due to the evenly spaced bumps of equal

height.The systemmeets the second requirement as the body

does not deviate more than 0.0058 meters (0.2 inches).

Displacement appears to peak around -0.022 meters (0.08

inches)around the 0.2 seconds mark. Note that the

displacement of the body is lower than the height of the bump

due to the compression of the springs and dampers.

The recommendation for systemparameters acquired from

the two simulations is the following:

Mass ofbody: 3,000 kg

Mass ofwheels, tires, and suspension:200 kg

Spring rate: 8,000,000 N/m

Damper constant:700,000 N*s/m

CONCLUSION

The largest error in the system is likely the pitch of the

body which can have a considerable effect on suspension

behavior. Lumping all the unsprung mass into one mass is also

unpractical given that the springs and dampers are only

partially included in the unsprung mass. It is also difficult to

translate the large spring constant of the tire into air pressure,

and tire properties. All things considered, the system still

simulates a commonly used suspension configuration, and can

be used in the design process so long as the user is aware of the

assumptions.

References

[1] Palm III, William. System Dynamics.2nd

. New York: McGraw Hill,

2014.](https://image.slidesharecdn.com/d9f33b7f-be17-4b95-8904-c431fbfe65df-151012180701-lva1-app6891/75/220-PROJECT-2015-2-2-2048.jpg)

![Graph 2:

Matlab commands:

m1 = 3000; %kg

m2 = 200; %kg

k1 = 8000000; %Newtons per meter (N/m)

k2 = 80000000; %tire has a very high spring constant unit: N/m

c = 700000; %N*s /m

A = [0 1 0 0; (-k1/m1) -c/m1 c/m1 c/m1; 0 0 0 1; k1/m2 c/m2 (-k1-k2)/m2 -c/m2];

B = [0;0;0;(k2/m2)];

C = [1 0 0 0];

D = [0];

car = ss(A,B,C,D);

A = [linspace(0,0,1250.25) linspace(0,0.076,1250.25), linspace(0.076,0.076,1250.25),

linspace(0.076,0,1250.25), linspace(0,0,25001)];

%t = linspace(0,15,30001)./11.76; %% SCENARIO 1

t = (0:0.01:20)./11.2; %% ** SCENARIO 2 **

%u = A %% ** SCENARIO 1**

u = 0.0254*sin(((2*pi)/0.3048)*t);% ** SCENARIO 2 **

lsim(car,u,t);](https://image.slidesharecdn.com/d9f33b7f-be17-4b95-8904-c431fbfe65df-151012180701-lva1-app6891/75/220-PROJECT-2015-2-4-2048.jpg)