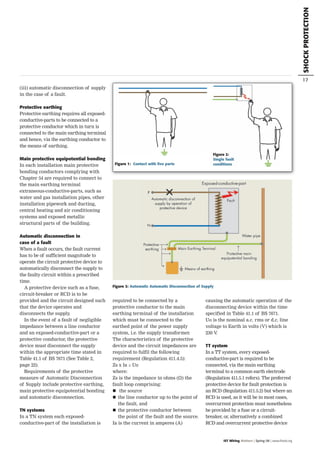

This document discusses various protective measures against electric shock as defined in BS 7671. It describes the key principles of basic protection, which protects against direct contact with live parts under normal conditions, and fault protection, which protects against indirect contact with normally non-live parts that have become live due to a fault. The main protective measures discussed are automatic disconnection of supply, double/reinforced insulation, electrical separation, and extra-low voltage provided by SELV or PELV. Requirements for each measure are outlined, including how basic and fault protection are provided. Diagrams illustrate potential shock risks.