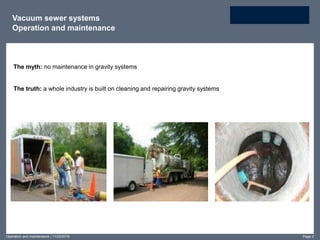

The document compares the operation and maintenance of vacuum sewer systems to gravity sewer systems. While there is a myth that gravity systems require no maintenance, the truth is that an entire industry exists to clean and repair gravity systems. Vacuum systems require regular checks of collection chambers and vacuum stations, as well as annual service and controller replacements every 10 years. Gravity systems require cleaning accumulated waste, rehabilitation, and pumping station maintenance. Vacuum systems have less operational risk and no confined space entry hazards. Overall, the document argues that while all sewer systems require maintenance, vacuum systems likely have lower maintenance costs than gravity systems.