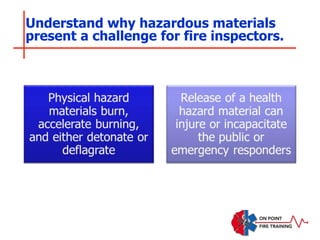

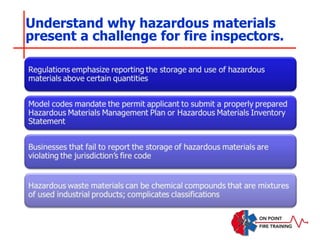

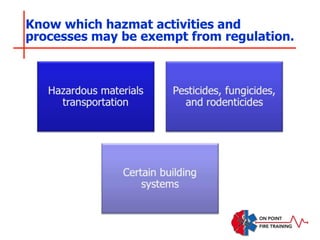

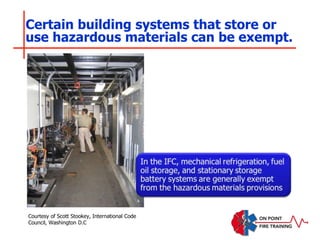

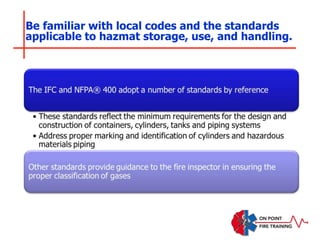

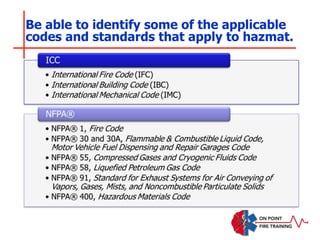

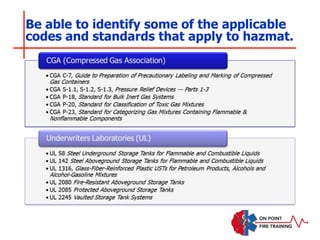

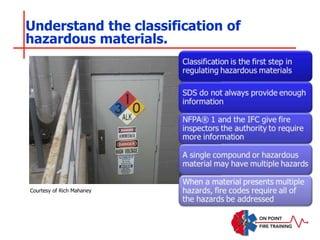

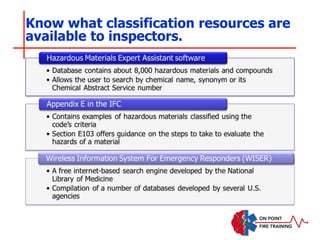

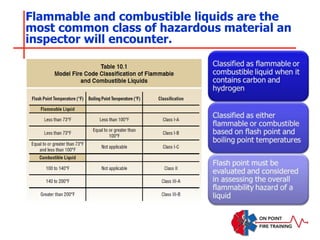

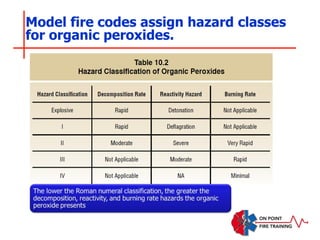

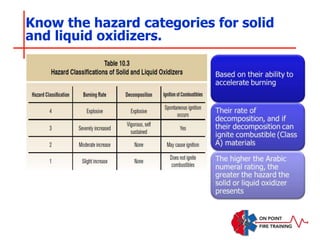

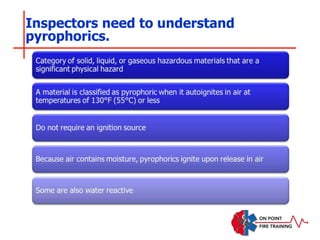

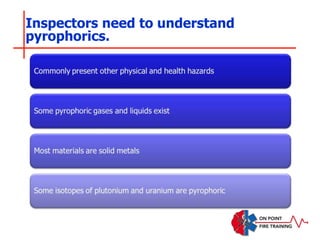

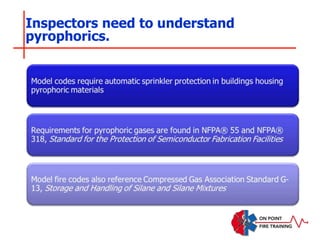

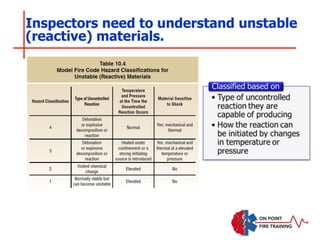

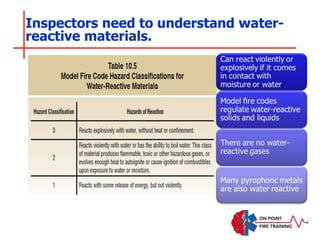

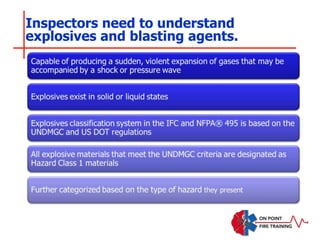

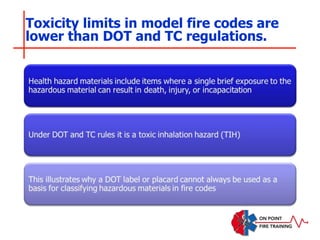

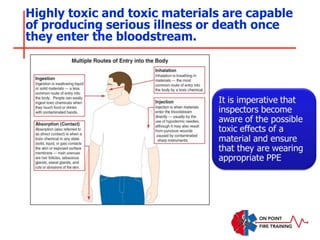

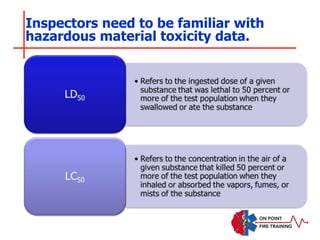

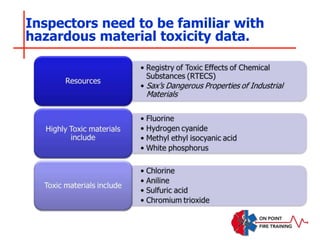

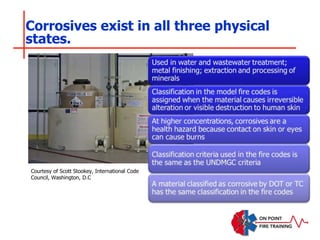

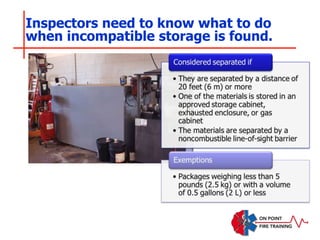

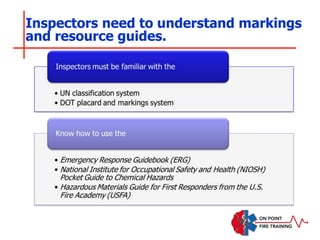

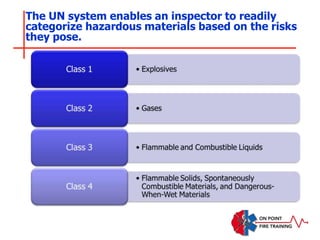

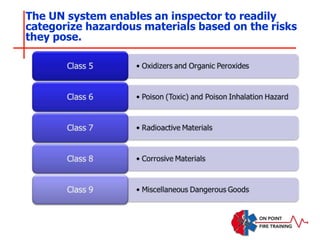

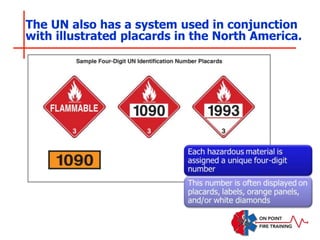

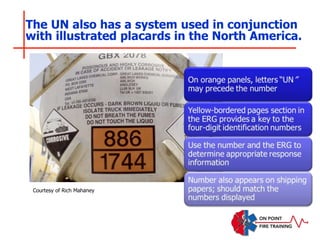

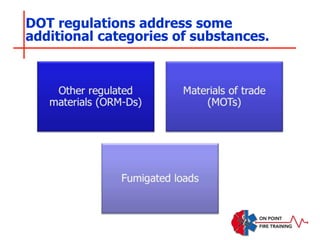

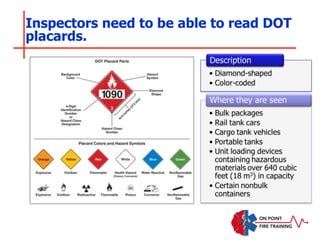

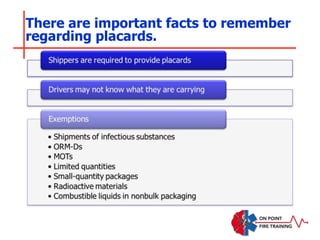

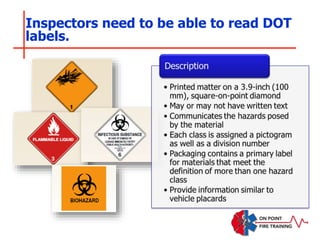

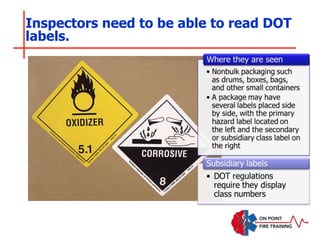

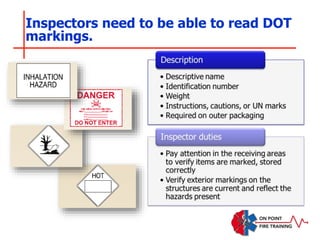

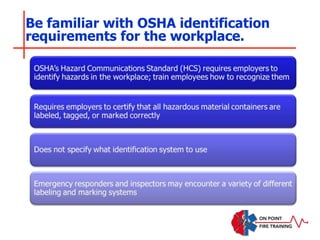

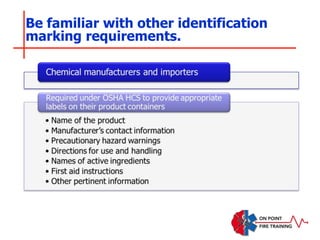

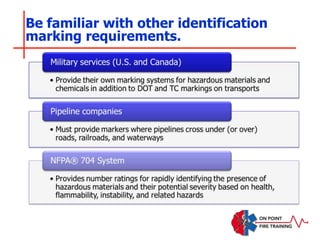

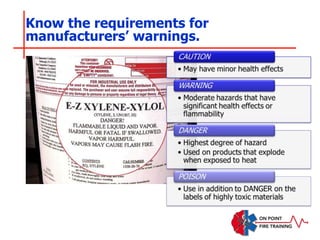

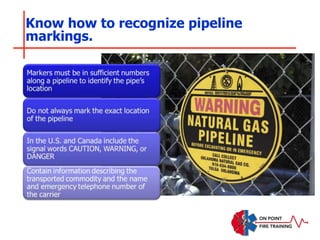

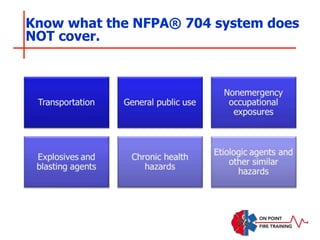

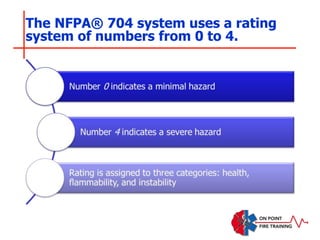

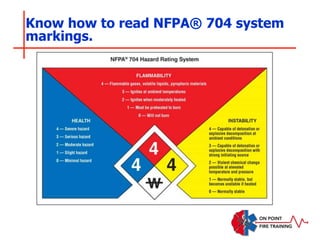

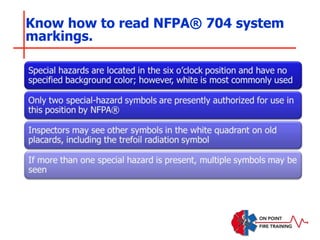

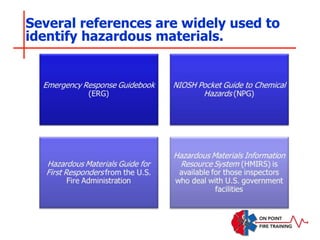

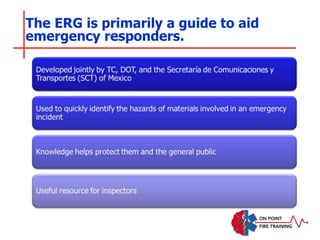

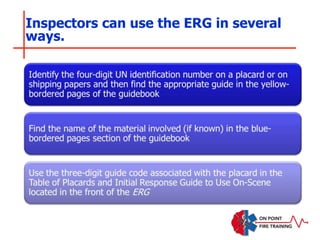

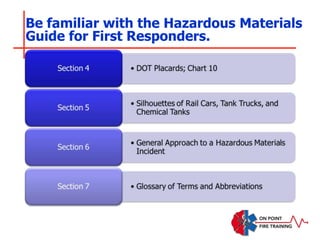

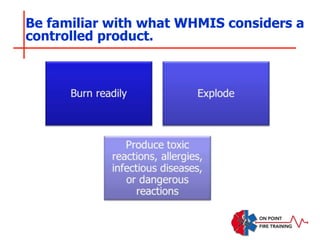

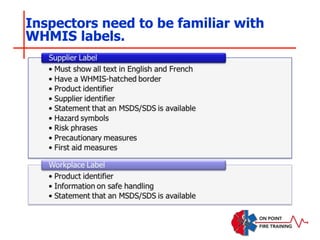

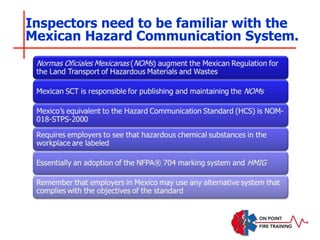

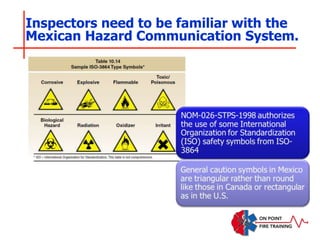

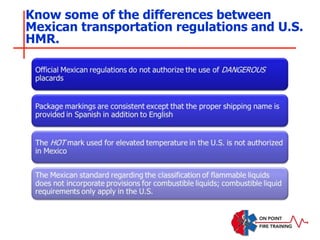

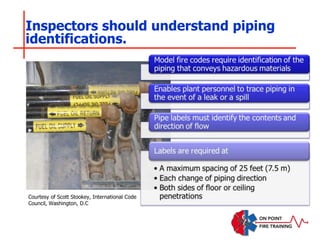

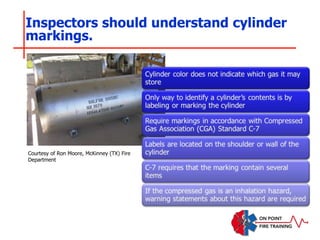

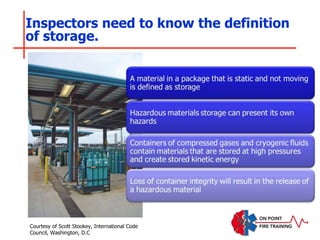

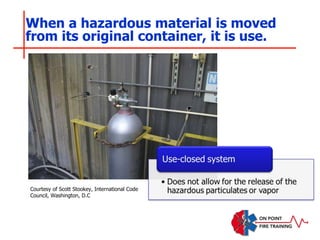

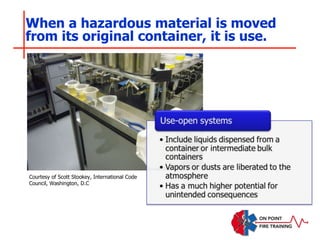

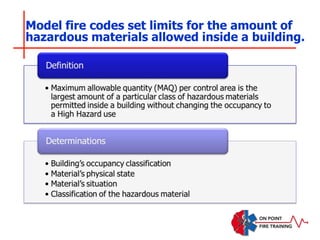

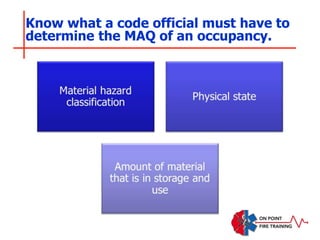

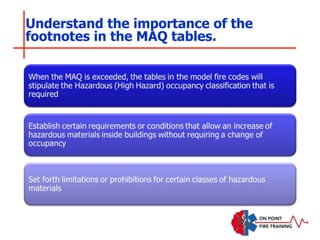

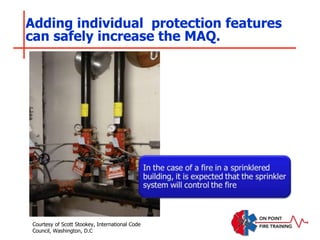

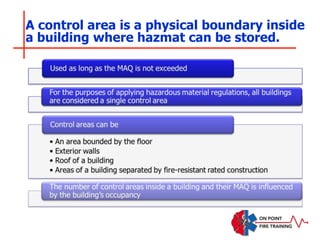

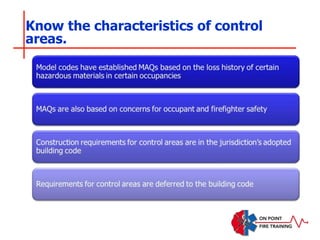

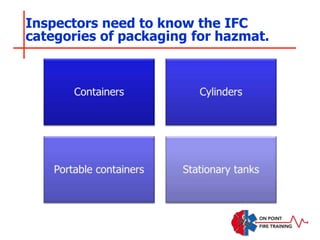

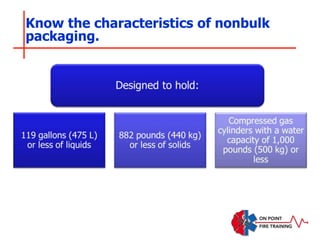

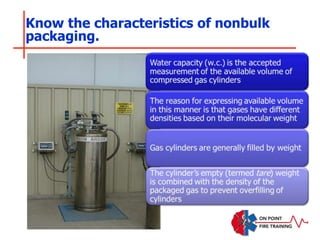

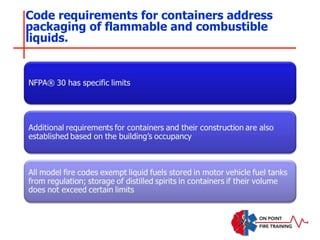

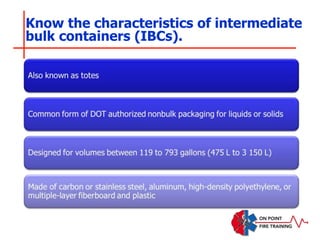

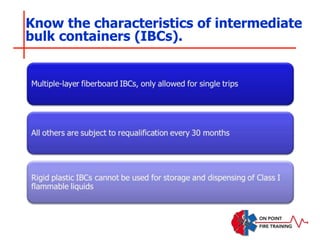

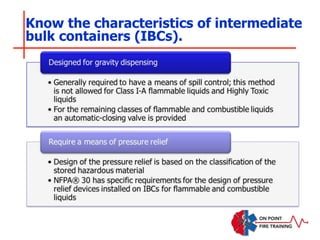

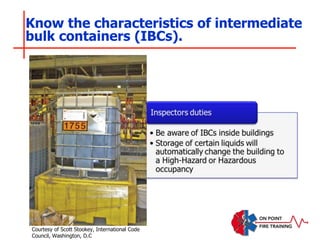

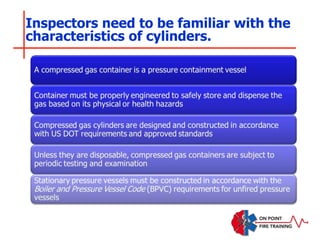

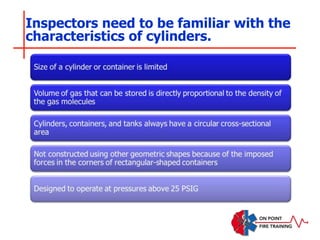

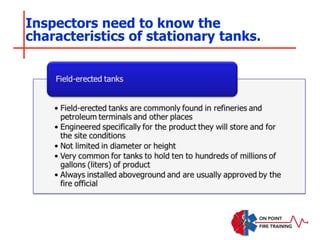

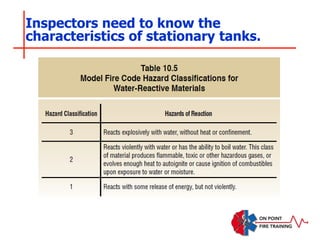

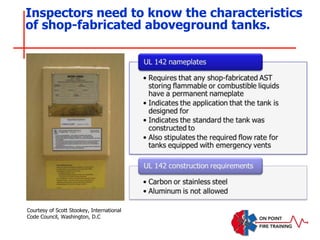

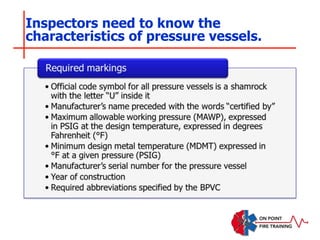

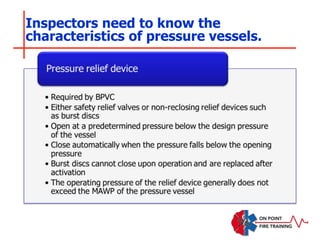

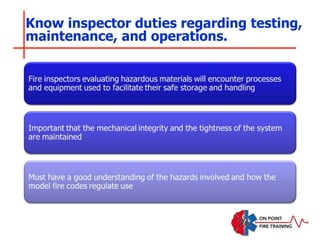

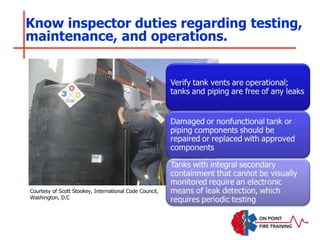

This document outlines learning objectives and key points about hazardous materials regulations and code enforcement. It discusses why hazardous materials present challenges for fire inspectors, the classification systems used to identify hazards, storage and packaging requirements, quantity limits, and inspection considerations for equipment, containers, and tanks. The main topics covered include physical hazard properties, health hazard toxicity, incompatible materials, markings and placards, permissible amounts, and testing/maintenance requirements.