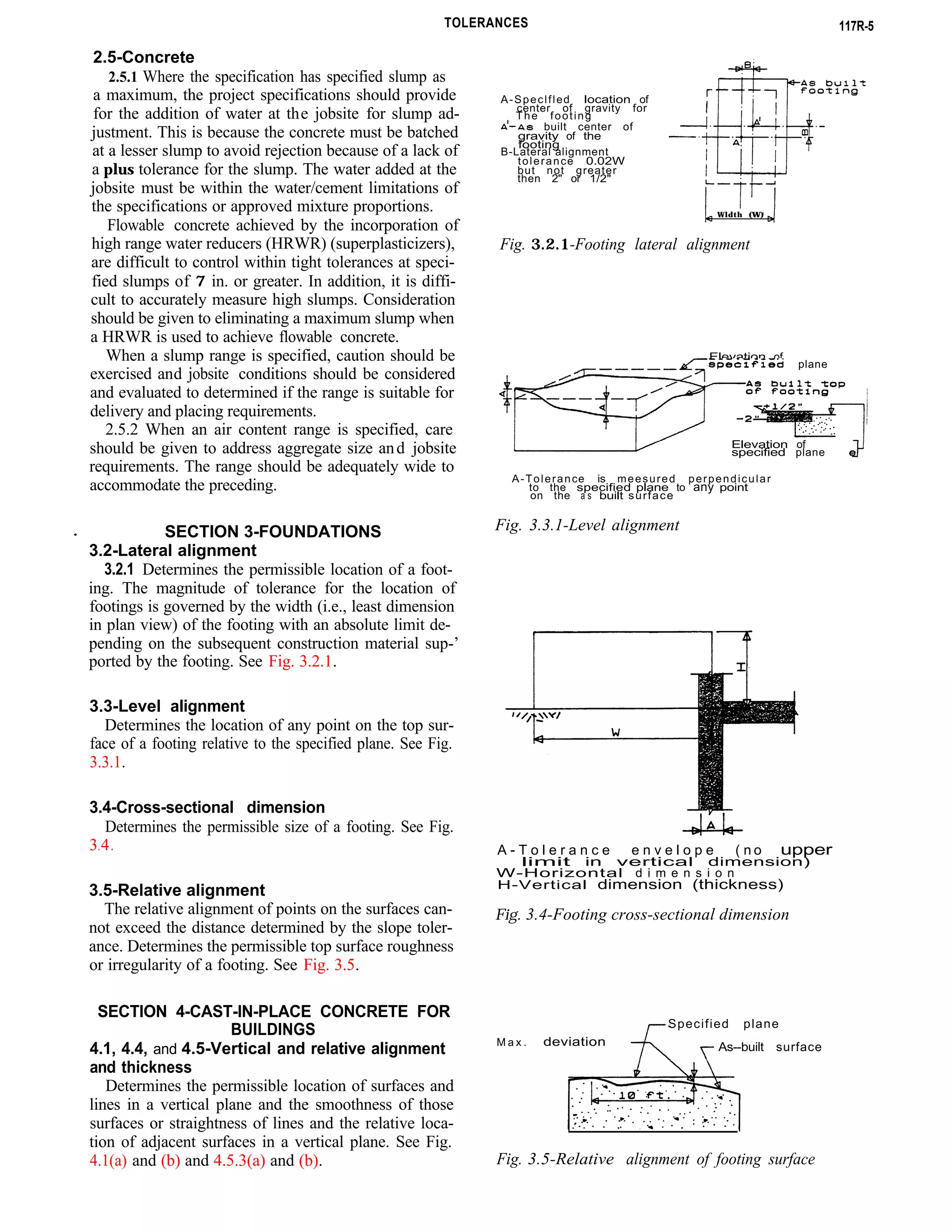

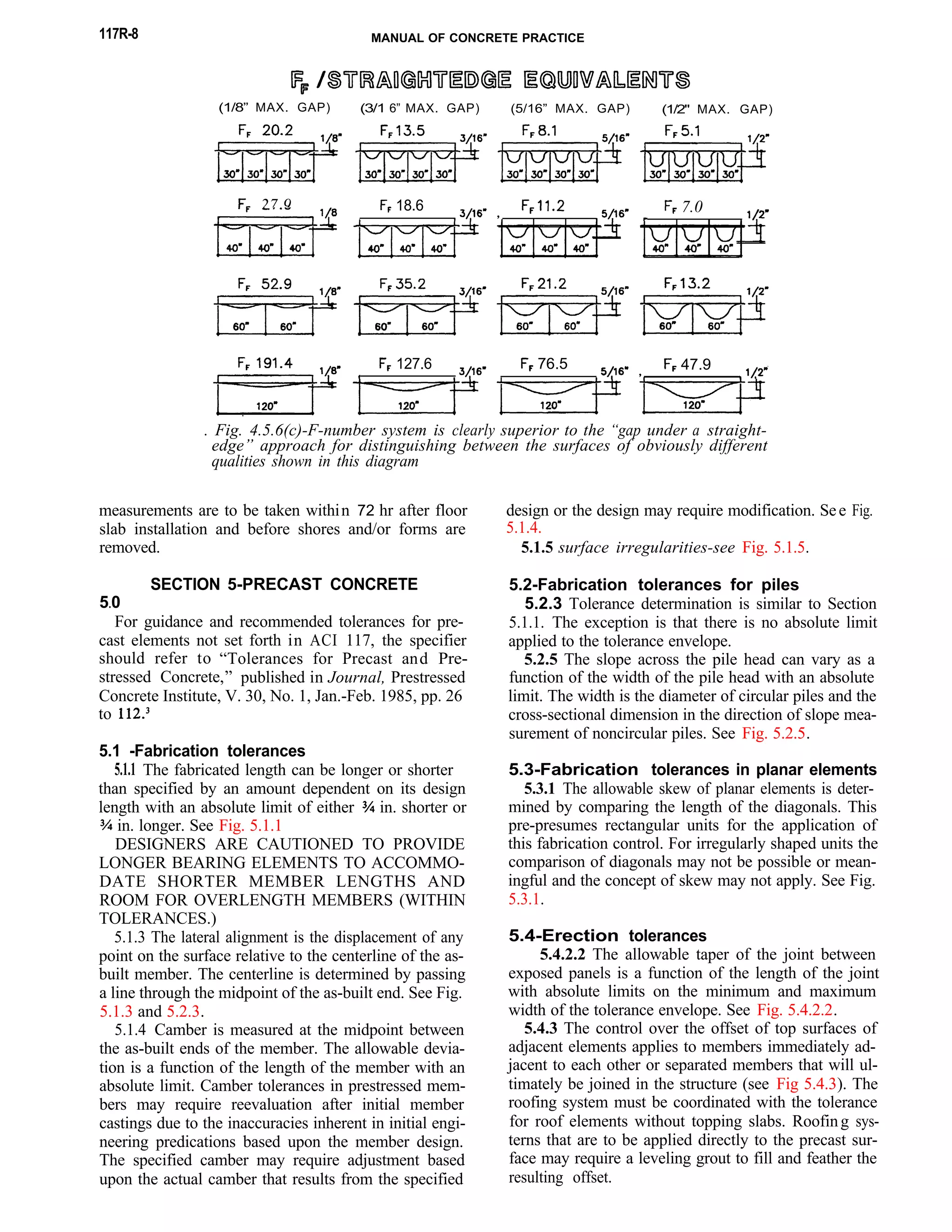

This document provides a commentary on ACI 117R-90, which establishes tolerances for concrete construction and materials. The commentary is intended to provide clarification and insight into how the tolerances in ACI 117R-90 should be applied. It discusses key definitions, provides figures to illustrate different types of tolerances, and offers commentary and guidance for applying the tolerances in ACI 117R-90 for materials, foundations, cast-in-place concrete structures, precast concrete, and other concrete construction applications. The commentary aims to help designers convey appropriate performance expectations to contractors through standardized tolerances while accounting for factors like structural requirements, economics, construction techniques and job site conditions.