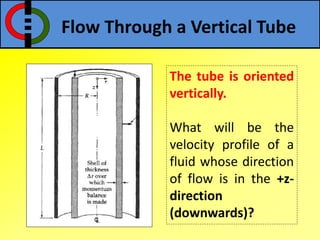

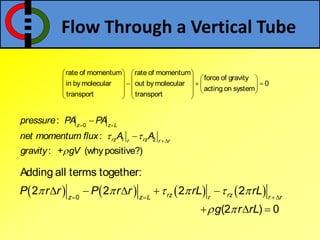

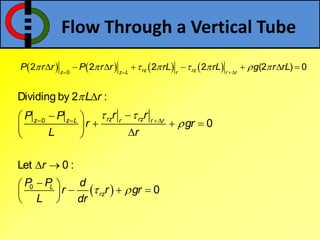

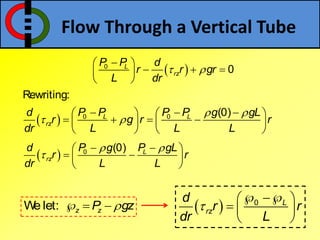

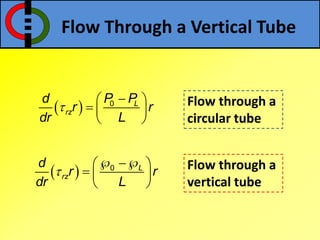

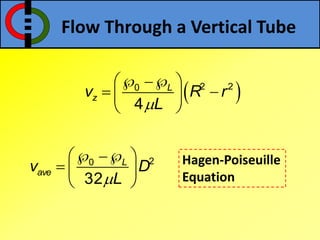

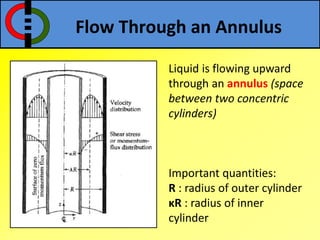

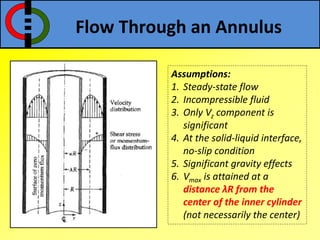

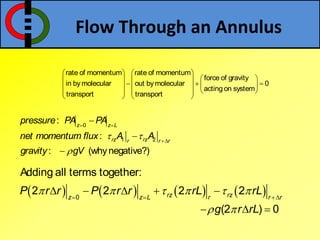

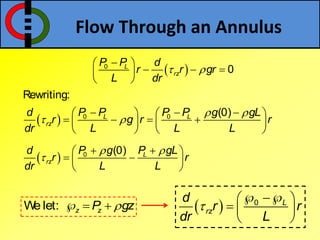

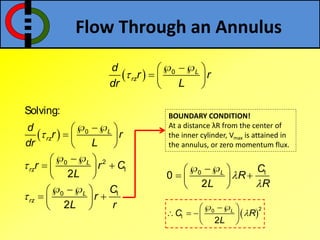

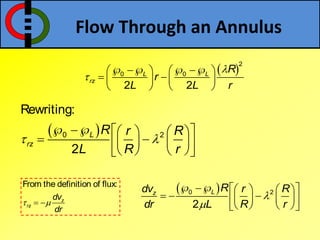

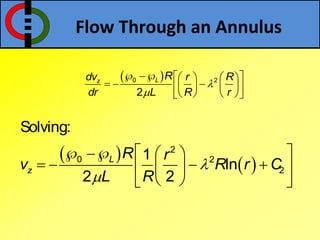

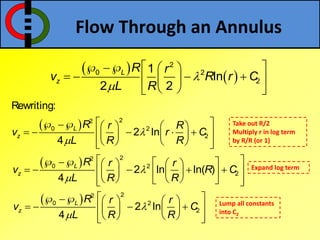

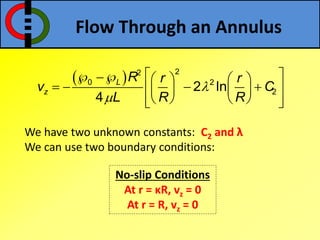

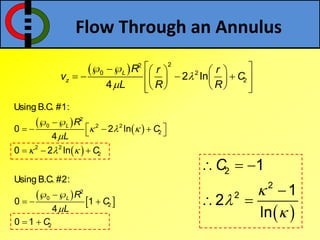

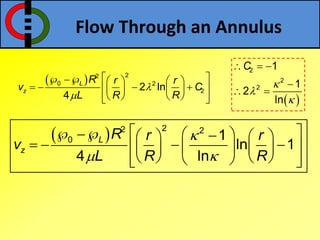

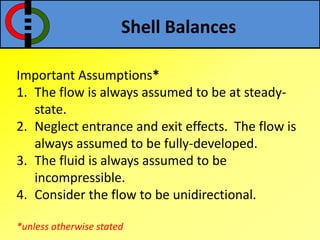

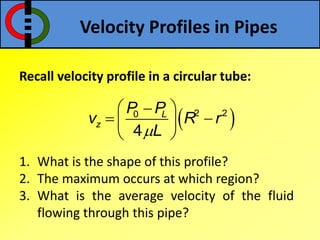

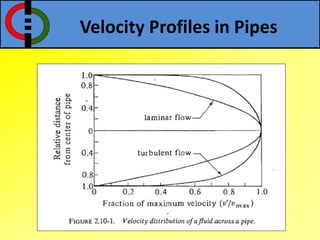

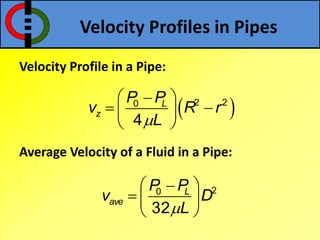

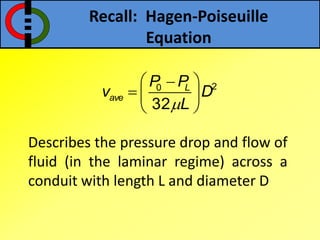

This document outlines flow through a vertical tube and an annulus. For a vertical tube, the momentum equation is developed showing that the velocity profile is parabolic. Gravity causes a downward acceleration. For an annulus, assumptions are made and the momentum equation is similarly developed. It is shown that the maximum velocity occurs at a distance λ from the inner cylinder and that the velocity profile takes a logarithmic form.