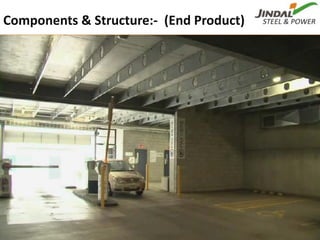

The document introduces the Speedfloor system, a unique suspended concrete flooring system for fast, lightweight composite floors. Some key points:

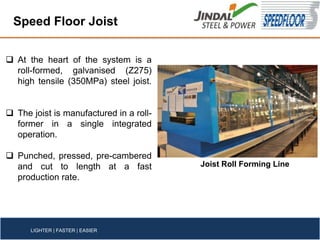

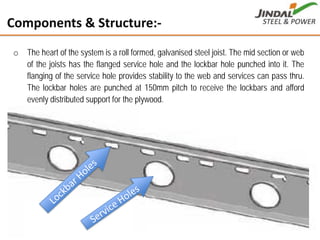

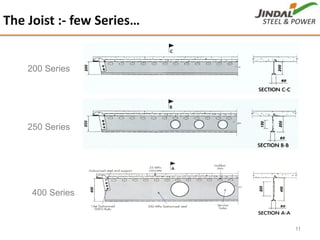

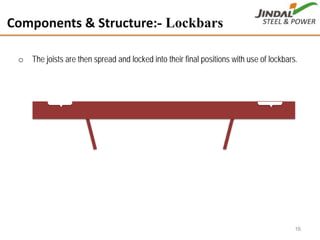

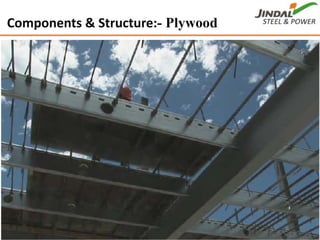

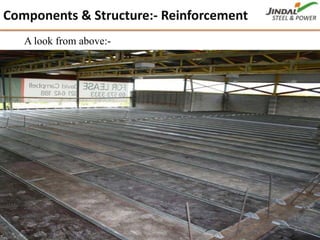

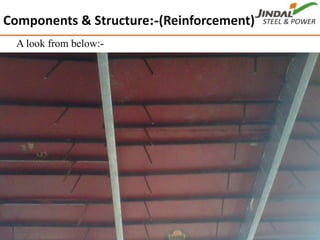

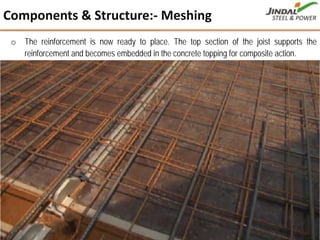

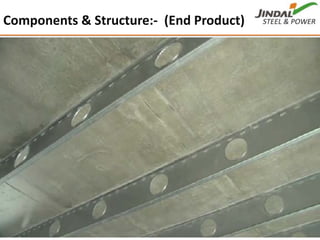

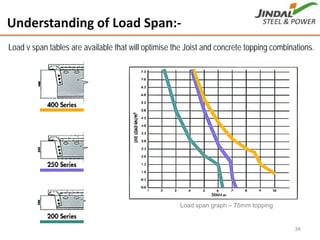

- The system uses rollformed steel joists that are lighter and faster to install than traditional methods.

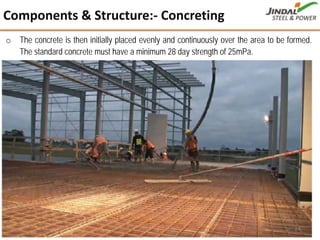

- It provides similar performance to poured concrete slabs but saves time and money through less curing time and no painting or hassles.

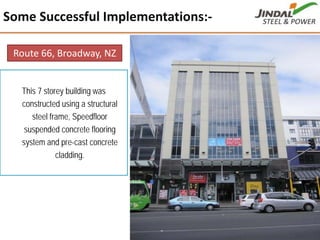

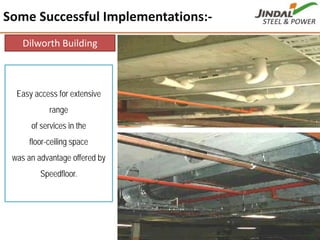

- The system has been successfully implemented in buildings in New Zealand and India, providing benefits like minimal foundations, weight savings, and easy accommodation of services.