Case study: Refinery mercury chemical decontamination in preparation for decommissioning

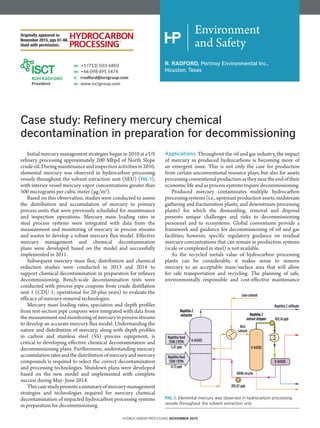

- 1. Environment and Safety R. RADFORD, Portnoy Environmental Inc., Houston, Texas Case study: Refinery mercury chemical decontamination in preparation for decommissioning Initial mercury management strategies began in 2010 at a US refinery processing approximately 200 Mbpd of North Slope crudeoil.Duringmaintenanceandinspectionactivitiesin2010, elemental mercury was observed in hydrocarbon processing vessels throughout the solvent extraction unit (SEU) (FIG. 1), with interior vessel mercury vapor concentrations greater than 500 micrograms per cubic meter (µg/m3 ). Based on this observation, studies were conducted to assess the distribution and accumulation of mercury in primary process units that were previously scheduled for maintenance and inspection operations. Mercury mass loading rates in steel process systems were integrated with data from the measurement and monitoring of mercury in process streams and wastes to develop a robust mercury flux model. Effective mercury management and chemical decontamination plans were developed based on the model and successfully implemented in 2011. Subsequent mercury mass flux, distribution and chemical reduction studies were conducted in 2013 and 2014 to support chemical decontamination in preparation for refinery decommissioning. Bench-scale decontamination tests were conducted with process pipe coupons from crude distillation unit 1 (CDU 1; operational for 20-plus years) to evaluate the efficacy of mercury-removal technologies. Mercury mass loading rates, speciation and depth profiles from test-section pipe coupons were integrated with data from themeasurementandmonitoringofmercuryinprocessstreams to develop an accurate mercury flux model. Understanding the nature and distribution of mercury, along with depth profiles in carbon and stainless steel (SS) process equipment, is critical to developing effective chemical decontamination and decommissioning plans. Furthermore, understanding mercury accumulationratesandthedistributionofmercuryandmercury compounds is required to select the correct decontamination and processing technologies. Shutdown plans were developed based on the new model and implemented with complete success during May–June 2014. Thiscasestudypresentsasummaryofmercury-management strategies and technologies required for mercury chemical decontamination of impacted hydrocarbon processing systems in preparation for decommissioning. Applications. Throughout the oil and gas industry, the impact of mercury in produced hydrocarbons is becoming more of an emergent issue. This is not only the case for production from certain unconventional resource plays, but also for assets processingconventionalproductionastheyneartheendoftheir economic life and as process systems require decommissioning. Produced mercury contaminates multiple hydrocarbon processingsystems(i.e.,upstreamproductionassets,midstream gathering and fractionation plants, and downstream processing plants) for which the dismantling, removal and disposal presents unique challenges and risks to decommissioning personnel and to ecosystems. Global conventions provide a framework and guidance for decommissioning of oil and gas facilities; however, specific regulatory guidance on residual mercury concentrations that can remain in production systems (scale or complexed in steel) is not available. As the recycled metals value of hydrocarbon processing plants can be considerable, it makes sense to remove mercury to an acceptable mass/surface area that will allow for safe transportation and recycling. The planning of safe, environmentally responsible and cost-effective maintenance Naphtha feed STAB 2 BTMs Naphtha 2 raffinate Lean solvent Rich solvent Naphtha 2 extract stripper Naphtha 2 extractor 892.14 ppb Naphtha feed STAB 1 BTMs 5.47 ppb V-04303 V-04305 V-04308 205.87 ppb OVHD recycle 0.73 ppb FIG. 1. Elemental mercury was observed in hydrocarbon processing vessels throughout the solvent extraction unit. Originally appeared in: November 2015, pgs 61-66. Used with permission. HYDROCARBON PROCESSING NOVEMBER 2015

- 2. Environment and Safety and decommissioning of mercury-impacted oil and gas facilities isimprovedwithanaccurateassessmentofmercurydistribution and the evaluation of applicable mercury-removal technologies. Results, observations and conclusions. Studies indicate that the mercury mass-loading potential of steel pipe exceeds estimates reported in previously published studies. Thermal desorption and chemical reduction bench testing indicate that theprocessisreversible,usingvariouschemistriesandmethods. Also, recent thermal desorption experiments performed on metallic test coupons in a quartz tube furnace indicate that field steam-out temperatures (100°C to 200°C) are ineffective in removing mercury from steel, but may still be effective in volatilizing hydrocarbon-soluble mercury and volatile mercury species. However, these species represent the smallest fraction of the total mass of mercury within the scale and steel. This can be precisely measured to quantify mercury emissions to atmosphere from the flare during degassing and chemical cleaning. Mercury removed from hydrocarbon processing systemsduringsteamingandchemicalcleaningcanbeadsorbed on media and removed from liquids so that the spent chemistry is rendered nonhazardous and suitable for routine disposal. Mercury vapors desorbed during steaming of hydrocarbon processpipingandvesselscanalsobeadsorbed/chemisorbedto various media, preventing release to the environment. Reactive fluid beds and reactive sorbent media used in both cases remain a waste streams that must be managed. Technical contributions.Datafrommercurymassfluxstudies using modified and improved methods, and integrated with the results of metallic coupon mercury mass loading, distribution and chemical reduction testing, has led to the development of advanced chemical decontamination methods and chemistries that are effective in removing 99% mercury mass and oxide scale (depth profile of 1 mm), deactivation of pyrophoric iron and encapsulation/removal of hydrocarbons. With the development of new mercury-removal chemistries came the development of new analytical methods to measure the performance of these chemistries during chemical decontamination and processing (waste minimization). Laboratory and field trials of the analytical method led to an improved understanding of economical and efficient mercury waste-minimization processes effective in removing mercury, metals, hydrocarbons and other contaminates. Mercury mass loading, distribution and chemical reduction bench scale studies are a key component of evaluating decontamination chemistries/methods and identifying the most cost-effective technology for application to mercury- impacted hydrocarbon processing systems. In an effort to better understandandquantifytheadsorption/desorptionofmercury in steel and processing, technical modifications to a proprietary sampling system were designed to allow for connection to plant flare systems to quantify mercury emissions from steaming and chemical cleaning operations. Crude oil laboratory comparison. The appearance of mercury at processing facilities can be delayed by months or yearsduetothescavengingofmercurybysteelpipelinesurfaces. It should be noted that this refinery is located approximately 500 mi from the supply, and that the first turnaround where condensed elemental mercury and volatile mercury were recorded in process systems occurred in 2010. A previous turnaround performed in 2005 on the SEU made no record of observed mercury. Although no mention was made of mercury in the 2005 turnaround, process stream sampling and analysis were not performed to verify the presence of mercury in process streams or equipment; however, mercury sampling was not standard at therefineryatthattime.Alaboratorycomparisonwasperformed on crude oil composite samples collected from the inlet feed to gain visibility into mercury concentrations and trends in crude oil processed by the refinery. There was some slight variability in the data reported from the three laboratories sourced for the study (4 ppb to 6 ppb); however, those concentrations are in the range of a previous study performed in 2004. Conclusions could not be made to support the duration of pipeline equilibrium or the possibility that new production could have caused a substantial increase in crude oil mercury concentrations. However, mercury accumulates and concentrates in process systems, and data from recent mass flux studies support the conclusion that 4 ppb to 6 ppb of mercury in inlet feeds is sufficient to produce process stream concentrations greater than 1,000 ppb. Mercurydistribution and chemical reduction.Turnaround and decommissioning planning should consist of attempts to determinetheextentandtypeofmercurycontaminationpresent in process systems. Routine mercury assessment sampling and analysis, along with mass flux studies performed throughout the lifecycle of an asset, provide valuable information required for decontamination and decommissioning planning. Data from mercury mass flux studies integrated with the results of metallic coupon mercury distribution, depth profiles and chemical reduction studies provide planners visibility into the process system and the means to design/modify select cleaning chemistries, chemical cleaning flow paths, temperatures and residence times based on accumulation rates, results of functional and molecular speciation and process design restrictions. Two separate mass flux studies were performed in January 2011 and August 2013 to understand the mercury sorption and distribution dynamics associated with process systems scheduledfordecontamination/decommissioning.Inthattime, the mass flowrate balance of the SEU in 2014 (process feeds vs. process outputs) indicated a potential mercury accumulation rate of 0.0003 lb/hr, which was an order of magnitude more accumulation than in 2011. Also, the concentration of mercury in the naphtha feeds to the SEU increased from approximately 5 ppb in 2011 to roughly 9 ppb in 2014, resulting in approximately 10 lb/yr of mercury being introduced into the process. Both mass flux studies clearly identified mercury sinks in the SEU, as well as net gains in mercury in process fluids as they moved through the system. As part of the mass loading study to support the 2014 chemical decontamination, a chemical reduction study was performed to focus on the development of chemistry effective in removing oxide scale, hydrocarbons and mercury from steel HYDROCARBON PROCESSING NOVEMBER 2015

- 3. Environment and Safety (FIG. 2). Once distribution, depth profiles, speciation and mass loading per surface area had been established (test section from C4 stream piping downstream of crude column overhead receiver), select test coupons were subjected to 14 chemical formulations and evaluated for mercury mass removal efficacy. For each chemistry tested, two coupons (primary and duplicate) were inserted into a treated SS chemical reaction chamber and then subjected to each test case chemistry for predetermined residence times. Process parameters (temperature, dissolved iron, pH, residence time, total mercury, flow, Re number) were collected every 20 min for the duration of the chemical test. Precise measurements, weights and microscope photos were taken of each coupon during inventory into the laboratory and post-chemical testing. Several test-case chemistries removed hydrocarbon, oxide scale and mercury from the surface to 1 mm in 4 hr at a temperature of 50°C. This is significant, as mercury mass loading rates were around 70 g/ m2 , which equated to around 35 mg of mercury per test coupon that had to be affected by the chemistries. The test case selected and deployed for the full-scale chemical cleaning program in 2014 had an efficacy of up to 99%, coupon mass loss of 2%, and depth of scale penetration of 0.51 mm. Chemistries used in this study included modifications to existing proprietary formulations, as well as some new formulations. Chemical decontamination. Deposition of mercury and its compounds can occur by adsorption, chemisorption, precipitation and/or condensation. The amounts of elemental mercury and its compounds in processed fluids affect all of these mechanisms. The uptake of mercury in steel is primarily through adsorption and chemisorption into the scale, making both carbon and SS excellent mercury scavengers. With some effort, this process can be reversed, depending on many factors (what goes in can come out). However, mercury complexed and incorporated into steel surfaces is not easily affected by typical hydrocarbon chemical decontamination chemistries and methods. Since 2005, Portnoy Environmental’s research group has concentrated efforts on understanding sorption dynamics of mercury in steel pipe and in the development of effective chemical decontamination solutions. On a scale, some chemistries are more effective than others for decontaminating mercury from hydrocarbon process systems, and each requires careful consideration before use. Generally, strong oxidizers and acids are the most effective, but they come with corrosion risks and can require additional processing steps to remove mercury from spent fluids. Mercury can be oxidized by oxidants including halogens, hydrogen peroxide, nitric acid and concentrated sulfuric acid. Using any of these options for mercury chemical decontamination in high concentrations, coupled with heat, should only be attempted by qualified chemical and industrial services companies. If the objective is strictly related to health and safety (e.g., for inspection), then the target may be to convert mercury to a nonvolatile species rather than to remove it. If the goal is to meet disposal requirements, then the decontamination process may be designed to convert mercury to a nonsoluble species so as to meet leachate criteria. Total mercury removal is possible for systems scheduled for abandonment and decommissioning, but as the chemicals used for this purpose are aggressive to mercury, they typically are to other metals as well. Less aggressive chemistries (aqueous noncorrosive surfactant/chelant blends) are easy to process, but, depending on mercury mass-loading rates and mass- removal objectives, they can require higher temperatures, increasedresidencetimesandmultipleapplicationtechnologies. Reactive chemistries react with mercury to form water-soluble or insoluble mercury (HgS), or otherwise combine with metal ions. Since mercury is soluble in hydrocarbons to a certain Flare Mercury removal vapor system Mercury removal liquids system Naphtha 2 extract stripper Hg compliance chemical liquid effluent spill point Compliance Hg vapor/liquid spill point Compliance Hg hydrocarbon vapor spill point Solvent recovery tower Steam/chemical injection Steam/chemical injection FIG. 3. During mercury decontamination in both 2011 and 2014, vapors and fluids were processed to minimize mercury emissions to atmosphere and to remove mercury and other contaminates from spent chemistries and condensates. 0 10 20 30 40 50 60 70 80 90 100 1 2 3 4 5 Chemical test formulation number Efficacy of test formulations Hgremoval,% 6 11 12 13 14 99.84 45.61 39.88 41.51 57.53 41.97 91.88 99.71 99.66 51.57 FIG. 2. A chemical reduction study was performed to focus on the development of chemistry effective in removing oxide scale, hydrocarbons and mercury from steel. HYDROCARBON PROCESSING NOVEMBER 2015

- 4. Environment and Safety extent (around 2 ppm), various surfactants and solvents are also effective in dissolving mercury and in removing organic solids. Generally, total mercury removal from a hydrocarbon processing system is not considered unless the system is scheduled for abandonment and decommissioning, or unless process risk reduction is required. For example, the turnaround in 2011 required systems with mercury accumulation rates ranging from 1 lb/yr to 100 lb/yr to be decontaminated to allow for extended maintenance activity over a 10-day period. The chemistry selected for this purpose was noncorrosive and designed to remove hydrocarbon-soluble and particulate mercury and to form soluble and insoluble mercury salts. The selected formulations of surfactants and chelants were applied in vapor phase and cascade phase over 12 hr to 24 hr with success in reducing interior mercury concentrations from around 1,000 µg/m3 to less than 1 µg/m3 , as continuously monitored from systems over the duration of maintenance. The goal for the 2014 SEU decontamination was decontamination in preparation for decommissioning, which generally requires 99% mercury mass removal to allow components to be processed at a metals recycler or reused at another processing facility. Chemistry selected for this purpose was a blend of surfactants (encapsulate metal ions and hydrocarbons), mineral acids, corrosion inhibitors, penetrants and chelants with a hydrogen sulfide scavenger. In both cases (mercury decontamination for reuse and decontamination for decommissioning), continuous performance sampling and analysis were performed to provide guidance on the effectiveness and duration of each chemical phase. Assimilation of this data provides an approximate total mass of mercury removed from each system. Because of the difficulty in capturing all the fractions, a more accurate method of determining mercury mass loss is by thermal desorption or aciddigestionofselectsteelfromprocessandcomparisontothe average mercury mass loading per surface area of pre-chemical application. Another verification method being pioneered is X-ray fluorescence analysis, which is yielding promising results with correct software and custom calibration standards. Spent chemistry and vapors processing. Chemical and processing procedures can be applied to spent fluids and condensates such that the materials are rendered nonhazardous and thus suited for nonhazardous disposal. Medias used for encapsulation, reaction or chemisorption, and filters used for colloidal particulate removal during processing, still need to be characterized and managed based on the results of waste characterization. Some commercial mercury-removal systems are targeted at vapor-phase treatment, and some are targeted at liquids. Vapor- phasetreatmentsystemsprimarilyconsistofsulfur-impregnated carbon, metal sulfide on carbon or alumina, and regenerative molecular sieve (zeolite), onto which is bonded a metal that amalgamates with mercury. Liquid-removal processes consist of iodide-impregnated carbon, metal sulfide on carbon or alumina, and silver on zeolite molecular sieves. Functional and molecular mercury speciations are not only important to developing effective chemical decontamination plans, but they are also important to planners for designing effective processing systems. In both cases (mercury decontamination for reuse in 2011 and decontamination for decommissioning in 2014), vapors and fluids were processed to minimize mercury emissions to atmosphere and to remove mercury and other contaminates from spent chemistries and condensates (FIG. 3). An innovative active fluid bed was designed and installed prior to solid media beds to minimize media changeouts. This new approach has exceptional mass-loading potential and cost benefits, and, when coupled with a solid media system, performs extremely well. As with chemical decontamination, continuous performance sampling and analysis are required to provide guidance on the effectiveness and duration of each phase of processing. As a means of determining how accurate the field analysis methods can be, an instrument detection limit study was performed with the field analyzer on each chemical formulation selected for the 2011and2014events.Inaddition,fieldduplicatesandlaboratory triplicates were analyzed for compliance of processing. A total of 100 Mgal of spent chemistry/condensates were processed (average pre-processing concentration of 500 ppb of mercury) during the 2011 turnaround to less than 7 ppb of mercury. As the chemistry used during the 2014 shutdown was more complex (thereby removing significantly more iron and mercury), additional processing steps were required to completelyneutralizeandprocess400Mgalofspentchemistry/ condensates with average mercury concentrations ranging from 500 ppm to less than 4 ppb of mercury. Compliance monitoring of flare. As a chemical element, mercury is not destroyed by a thermal oxidizer, but is only convertedtootherchemicalforms.Althoughsteamingequipment may remove some volatile mercury species and hydrocarbon- solublemercury,thetemperaturesaretoolowtoaffectcomplexed mercuryinsteel.Manyhydrocarbonprocessingplantsarelocated nearenvironmentallysensitiveareas,andmercuryemissionsfrom steaming to flare and materials processing should be considered and mitigated (FIG. 4). A considerable amount of mercury can be released to the atmosphere from steaming and chemical cleaning of mercury- contaminated systems during turnarounds and shutdowns FIG. 4. Many hydrocarbon processing plants are located near environmentally sensitive areas, and mercury emissions from steaming to flare and materials processing should be considered and mitigated. HYDROCARBON PROCESSING NOVEMBER 2015

- 5. Environment and Safety (FIG. 5). Therefore, during both the 2011 turnaround and the 2014 shutdown, mercury emissions to atmosphere were quantified and recorded for compliance. This is a complicated and challenging vapor stream to sample, and required certain modifications to the mercury-sampling systems. Measurements have shown that mercury vapor concentrations during active steaming and chemical cleaning can range from less than 1 µg/m3 to greater than 6,000 µg/ m3 , while condensate concentrations can range from less than 1 µg/L to 200 µg/L. The higher mercury concentrations are measured during chemical cleaning as mercury is oxidized and volatile mercury is released from scale and substrate surfaces. The total amount of mercury released to the atmosphere from crude oil processed in the US is approximately 11 t, which is around 7% of the US total (158 tpy). It should be noted that turnaround waste streams (e.g., fluids, vapors and gases) and other potential sources of mercury were not included in the aforementioned atmospheric emissions; therefore, these potential additional sources should be considered when developing a mercury management strategy. Note: At the conclusion of chemical decontamination for preparation of decommissioning, planners should consider that the flare line will likely also require mercury decontamination. RON RADFORD is the vice president of PEI’s Mercury and Chemical Services (MCS) Group in Houston, Texas. He develops international mercury management projects with alliance partners in Australia, Africa and the Middle East, while strengthening MCS Group’s core businesses in the Americas. He also manages PEI’s mercury mass loading, distribution and chemical reduction research and development program to support mercury chemical decontamination of operating assets, along with assets scheduled for decommissioning. FIG. 5. A considerable amount of mercury can be released to the atmosphere from steaming and chemical cleaning of mercury- contaminated systems during turnarounds and shutdowns. ePrinted and posted with permission to Portnoy Environmental, Inc. from Hydrocarbon Processing November © 2015 Gulf Publishing Company