Fermentation new

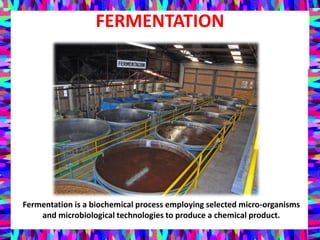

- 1. FERMENTATION Fermentation is a biochemical process employing selected micro-organisms and microbiological technologies to produce a chemical product.

- 2. DESIGN OF THE FERMENTATION PROCESS Any fermentation process design must consider three major aspects: (i) Value creation opportunity (ii) Process design analysis (iii) Objectives of the design project

- 3. I. VALUE CREATION OPPURTUNITY It concerns mostly establishment of microbial reaction process and its development recognizing economic opportunity. To create and deliver value in an efficient enough way that it will generate profit after cost. IMPORTANCE? Because value creation is the starting point for all businesses, successful or not, it's a fundamental concept to understand.

- 4. Recognition Of Economic Opportunity Relates to the Appropriateness Of: 1. SELECTION OF MICROBIAL STRAINS 2. SELECTION OF APPROPRIATE FERMENTER DESIGN 3. SCOPE OF PRODUCT UTILIZATION

- 5. Exploitation Of Microbial Activity Is Done Considering: Selection of new stable strains for getting a share in the market by producing useful new products using modern fermentation plant. Selection of stable strain for known product of the established equipment.

- 6. DESIGN OF THE FERMENTER For production of a substance having established market, combination of an existing stable strain and a simplified fermenter together with new devices need to be used. In almost all fermentation processes the fermenter configuration plays the part of a mediator between energy input variables and physiological reactions of microbial cultures. As microbial behaviour vary widely, it is difficult to design a versatile fermenter for multipurpose use. This limitation led to the development of various conventional and non-conventional fermenter designs.

- 7. DESIREABLE REQUIREMENTS OF A FERMENTER

- 8. High power demand and underutilization of impeller energy input are the two important weak points of conventional designs. In any new design, principles of unconventional fermenters have been to minimize these shortcomings of conventional fermenters. Also, care is needed in the interaction between fermenter design and microbial unit at used physiochemical environment to make “the downstream processing of the product ”easier. Downstream processing refers to the recovery and purification of biosynthetic products, particularly pharmaceuticals, from natural sources such as animal or plant tissue or fermentation broth, including the recycling of salvageable components and the proper treatment and disposal of waste.

- 9. INTEGRATION OF MICROBIAL UNIT WITH DOWNSTREAM PROCESSING

- 10. SCOPE OF THE PRODUCT It is associated with the “mode of utilization” of the product to get an adequate fitness of the product on human needs.

- 11. II. PROCESS DESIGN ANALYSIS Fermentation time course and profiles of state and control variables. Determination of most favorable control variables condition to obtain maximum product yield. Pilot plant studies for new process development thereby aid in innovation in scale up. Investigating possibilities of innovation by the process simplification and by adopting high technology easily and successfully.

- 12. Product development such that marketing is decisive. Yield equilibrium specific rates of fermentation and growth profiles. Product concentration in finished broth, fermentation cycle or fermentation rate and product recovery process.

- 13. III. OBJECTIVES OF DESIGN AIM PROCEDURE PROJECTED DESIGN AND DEVELOPMENT1 . Product development 2. Possibilities of producing new type of microbial group in a known fermenter design 3. Process improvement ORGANIZATION STRUCTURE

- 14. ISOLATION OF FERMENTATION PRODUCTS The innumerable products synthesized using industrial fermentations can't directly be consumed/used, rather they need to be harvested, purified, packaged and tested before they could be put to their actual use. This step is called as “DOWN STREAMING” It is an important step in the production of pharmaceuticals like: 1. Antibiotics such as penicillin 2. Hormones such as insulin and human growth hormone 3. Antibodies such as infliximab and rituximab 4. Vaccines 5. Antibodies and enzymes used for diagnostic purposes 6. Industrial enzymes 7. Natural fragrance and flavor compounds

- 15. Downstream processing is generally considered to be a specialized field in biochemical/chemical engineering. It encompasses harvesting, purification and packaging of a specific industrial product synthesized in marketable quantities. Analytical bioseparation refers to the separation or purification of biological products at different scales of operation, done at analytical scale, the purpose of which is to maintain the desired quality of the product. Downstream processing involves four important steps that result in the following progressive improvements in purity and concentration of the desired product…

- 16. 1. Removal of insoluble: This step involves the harvest of the product in the form of solute in a particle-free supernatant. An example of this is the separation of cells, cell debris or any other particulate matter from the spent fermentation broth containing an antibiotic. This can be achieved by various methods like filtration, centrifugation, sedimentation, flocculation, electro- precipitation, precipitation, and gravity settling. Other methods such as grinding, homogenization, or leaching, may be required for recovering products from solid sources like plant and animal tissues.

- 17. 2. Product isolation This step involves the removal of those components whose properties differ significantly from that of the desired product. For maximum products, the presence of water in them is the main impurity, and consequently, product isolation essentially involves drying and concentrating the product. This step involves processes such as solvent extraction, adsorption, ultra filtration, and precipitation.

- 18. 3. Product purification: This step is performed for separating those contaminants whose physical and chemical properties closely resemble those of the product. Since this is rather difficult to carry out, the steps involved at this stage may be expensive, and may require sensitive and sophisticated apparatus. This stage alone may use up a significant fraction of the entire downstream processing expenditure. Examples of some of the methods used in this step are affinity chromatography, size exclusion chromatography, reversed phase chromatography, crystallization and fractional precipitation, all of which are very specific techniques.

- 19. This is the last step that involves final processing steps that end up with a stable, functional, easily transportable and convenient product. This step involves processes like crystallization, desiccation, lyophilization and spray drying. Depending on the type of product and its application, polishing might even include product sterilization and removal/deactivation of trace contaminants that may compromise product safety. It might virus removal too. 4. Product polishing:

- 20. Not every product essentially requires all the above mentioned steps. Some products may be recovered by a combination of just two steps. For example, using affinity chromatography, one can isolate and purify a product in a single step.

- 21. FERMENTATION PROCESS FOR PENICILLINS: Penicillin was the first important commercial product produced by an aerobic submerged fermentation. Earlier it was made from the fungus, Penicillium notatum. Nowadays different species, Penicillium chrysogenum and better extraction processes are used. It requires lactose, other sugars and a source of nitrogen (yeast extract) in the medium to grow well. It is a secondary metabolite so it is only produced during the stationary phase. It requires a batch fermenter, and a fed batch process is usually used to prolong the stationary period and hence increase production.

- 22. Downstream processing is relatively easy since penicillin is secreted into the medium so there is no need to break open the fungal cells. However, the product needs to be very pure since it is to be used as a medical therapeutic drug so it is dissolved and precipitated as a potassium salt to separate it from other substances of the medium.

- 24. The resulting penicillin is called as Penicillin G. It can be chemically and enzymatic ally modified to a variety of penicillins with slightly different properties. These semi synthetic penicilins include: 1. Penicillin V 2. Penicillin O 3. Ampicillin 4. Amoxicillin

- 25. FERMENTATION PROCESS FOR STREPTOMYCIN: Streptomycin is a secondary metabolite produced by Streptomyces griseus. Change in environment condition and substrate availability influences final product. A soya bean based medium is used along with glucose as a carbon source.

- 26. PHASES DURING FERMENTATION PHASE 1: Rapid growth producing mycelial biomass. Little production of Streptomycin is obtained. PHASE 2: Additional production of mycelium. Streptomycin accumulates in the medium. Proteolytic activity of the microbe releases NH3 to the medium from the soybean meal, causing a rise in pH. PHASE 3: Process has completed. Finally the mycelium is separated by filtration and antibiotic recovered. The glucose and NH3 released are consumed during this phase. The pH remains fairly constant-between 7.6 and 9.0.

- 28. FERMENTAION PROCESS FOR TETRACYCLINES Recently it has been discovered that microorganisms of the genus Streptomyces which produce chlortetracycline, will also produce tetracycline particularly if the chloride ion concentration of the fermentation medium is kept low. This can be done by providing fermentation media from which chloride ions are excluded, either by making up the fermentation medium with chloride-free components or by treating the medium with agents which re move or sequester the chloride ions, thus making them unavailable for the formation of chlortetracycline. Unfortunately some of the most effective components of fermentation media for the production of the tetracycline antibiotics contain substantial quantities of chloride ions. Corn steep liquor is one of the most effective nutrient substances for the production of the tetracycline antibiotics as well as many other antibiotics. Apparently, this natural material contains something that is especially desired by the fermenting microorganism. Highest yields of antibiotic are, therefore, obtained when a portion of corn steep liquor is included in the aqueous nutrient medium.

- 30. FERMENTATION PROCESS FOR VITAMIN B12 Large scale industrial production of vitamin B12 occurs via microbial fermentation, predominantly utilizing Pseudomonas denitrificans, Propionibacterium shermanii, or Sinorhizobium meliloti. However, these strains have several shortcomings, such as long fermentation cycles, complex and expensive media requirements, and a lack of suitable genetic systems for strain engineering.

- 31. Carbon Sources: Corn Steep Glucose, Beet Molasses, Soya bean Meal/Glucose Nitrogen sources: Ammonium phosphate , Ammonium hydroxide

- 32. Recently, engineers have shifted their attention to Escherichia coli as a platform for vitamin B12 production.

- 33. THANK YOU RAVLEEN KAUR V SEMESTER B.PHARMACY UIPS,PU.