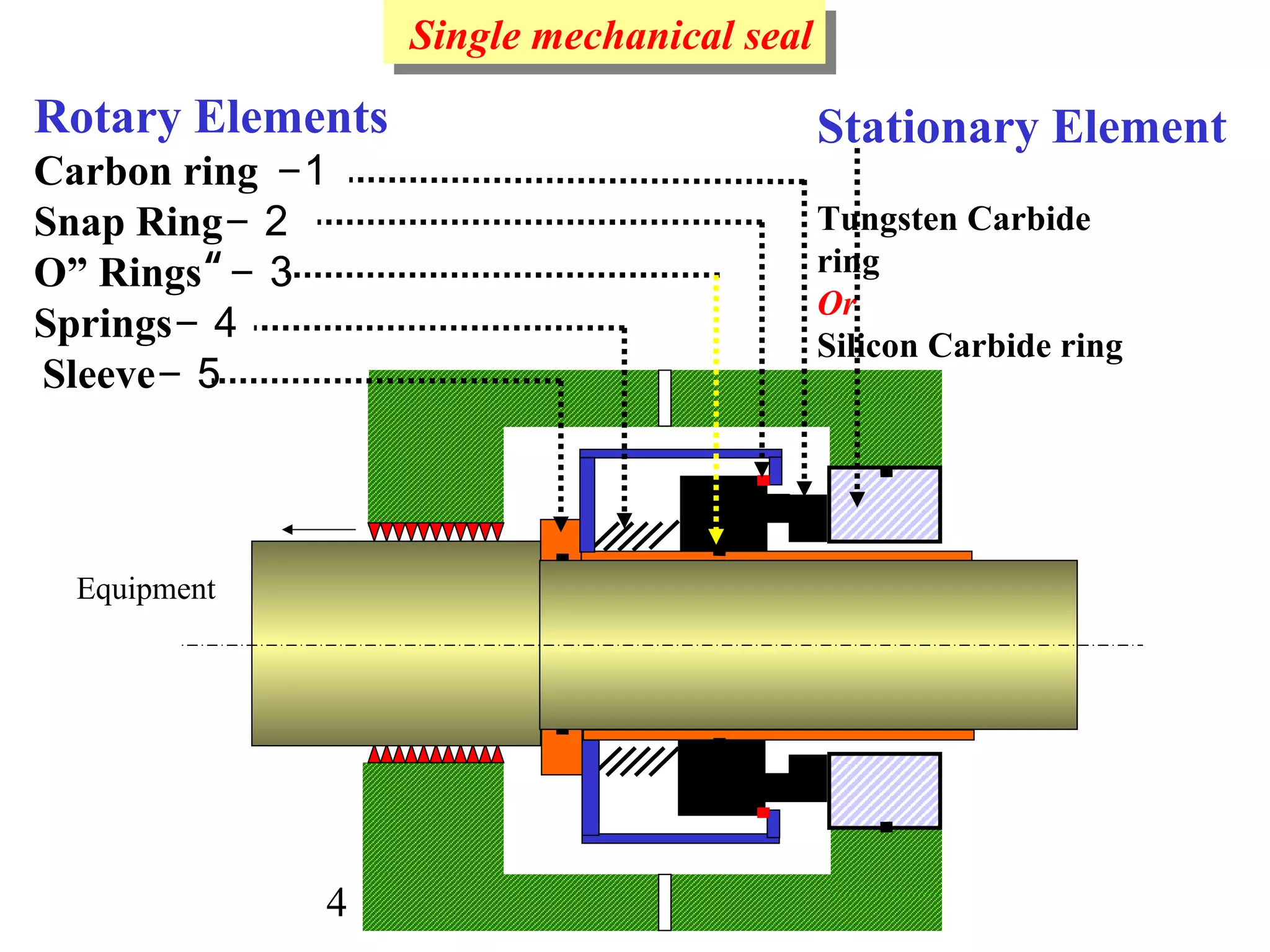

The document discusses mechanical seals and their components. It describes single and double mechanical seals, as well as unbalanced and balanced mechanical seals. It also discusses tandem seals, barrier fluids, and calculating hydraulic balance percentage. Mechanical seals are used to prevent shaft wear by providing a replaceable surface that wears instead of the shaft. Barrier fluids are used to lubricate and cool mechanical seals, with different fluids used depending on the operating temperature range.