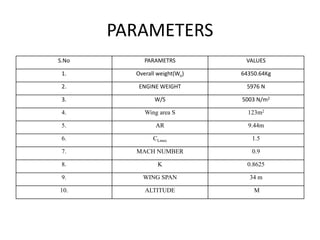

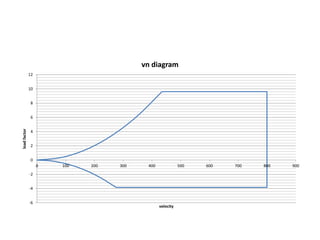

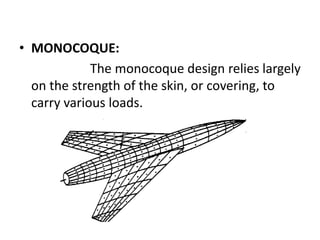

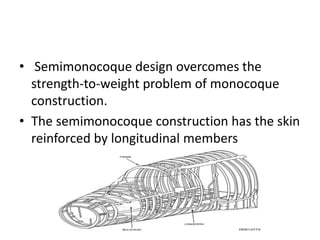

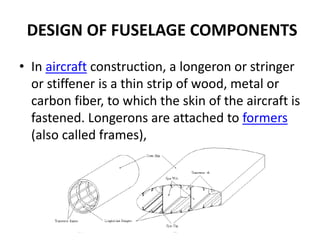

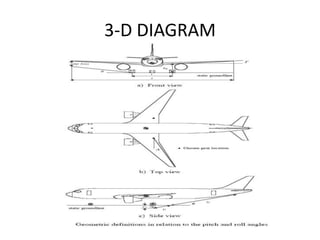

This document outlines the design of a 150-seater transport aircraft. It includes parameters like overall weight, wing area, aspect ratio, and engine selection. It discusses the v-n diagram that limits external loads on the aircraft and describes gust loads. It also covers wing design considerations like cell construction and materials used like titanium alloys and carbon fiber. The document summarizes fuselage design approaches like monocoque and semimonocoque. It concludes with noting the challenges of aircraft design and lessons learned.