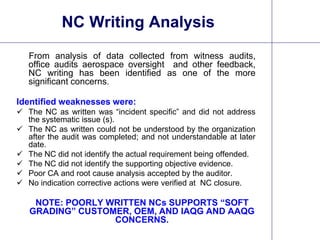

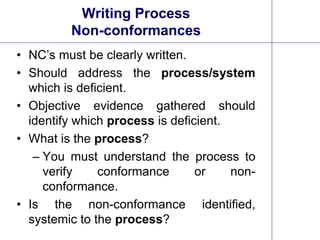

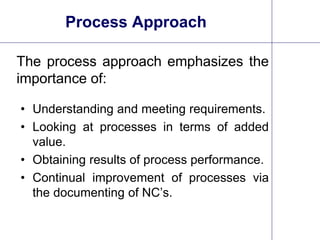

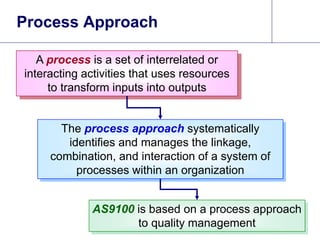

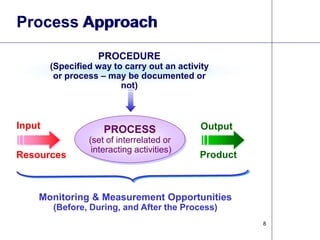

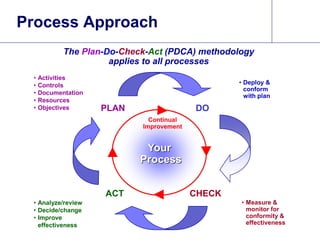

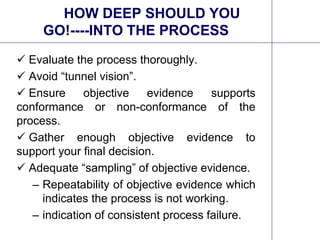

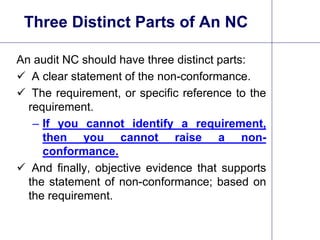

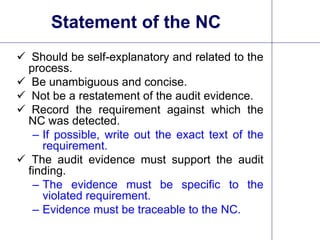

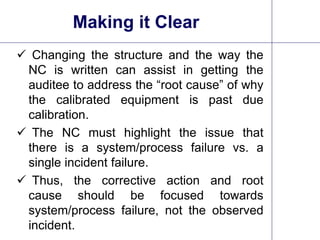

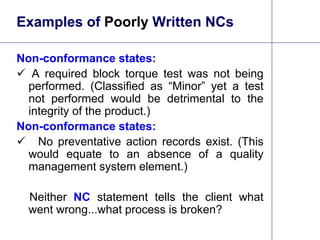

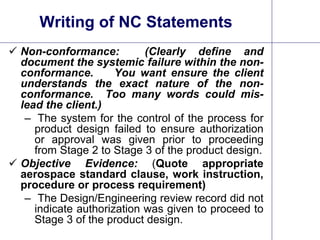

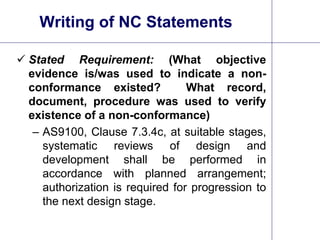

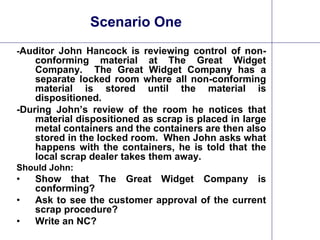

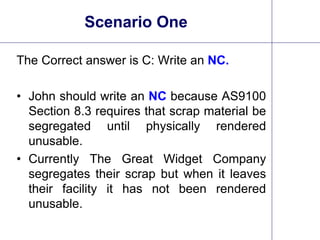

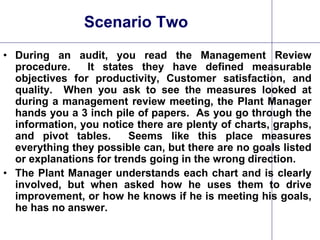

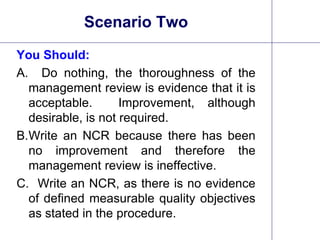

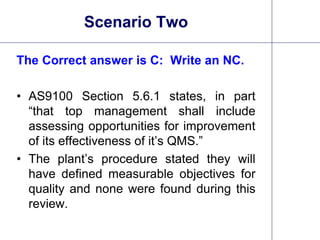

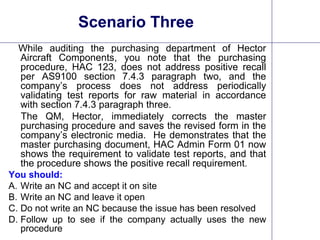

The document provides guidance on writing clear and concise non-conformances (NCs). It discusses analyzing NCs, the key parts of an NC, and making the NC understandable. It emphasizes writing NCs that address systemic process issues rather than just specific incidents. The document also discusses understanding the process approach and using objective evidence to support NCs. Examples are provided of poorly written NCs compared to clearer NCs that identify the requirement violated and support this with evidence.