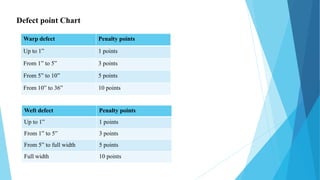

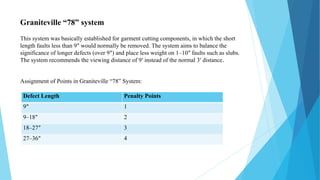

This document discusses fabric inspection systems used in the garments industry. It describes four main inspection systems: the 4-point system, 10-point system, Graniteville "78" system, and Dallas system. Each system involves identifying fabric defects and assigning penalty points based on defect length and severity. The 10-point system separately inspects warp and weft directions. The goal of inspection is to detect defects early to avoid wasting time and money on defective garments. Inspection occurs at various stages of production from pre-production to final product. Both textile suppliers and garment manufacturers are responsible for ensuring fabrics meet buyer standards through inspection.

![Some general rules for 4 point system

Not one meter of cloth is penalized more than 4 point.

Any defect occurring repeatedly through out the entire piece is marked second. [Second

is a cloth quality which implies that the cloth contains minor defects. A trade discount

of 8-15 is allowed in this category.]

Cloth is inspected on face side only unless specified.](https://image.slidesharecdn.com/fabric-inspection-system-190414085602/85/Fabric-inspection-system-6-320.jpg)