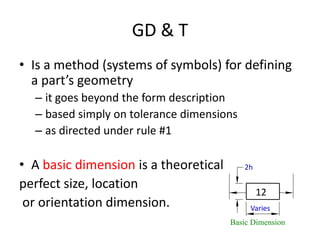

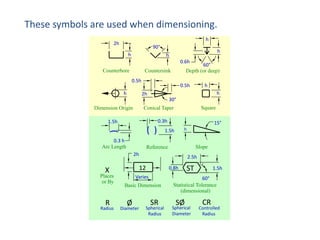

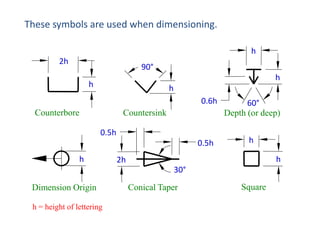

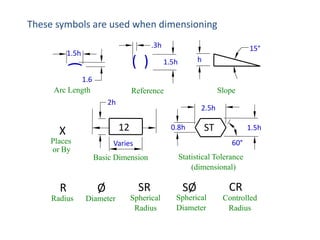

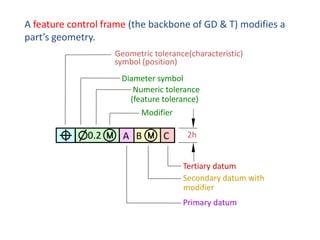

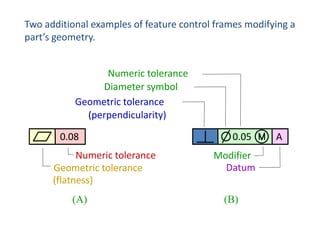

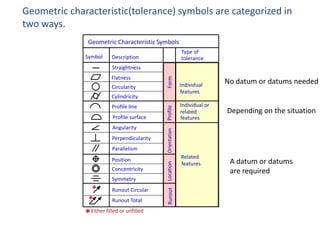

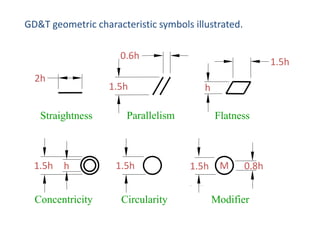

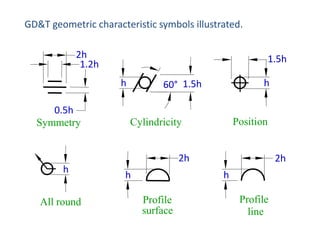

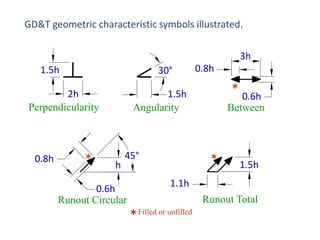

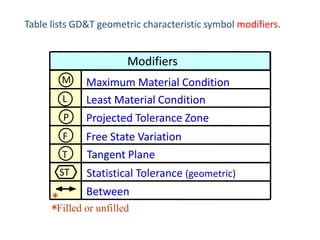

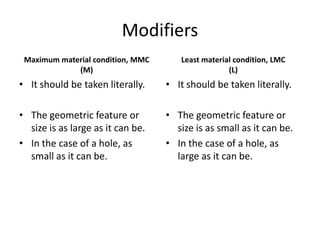

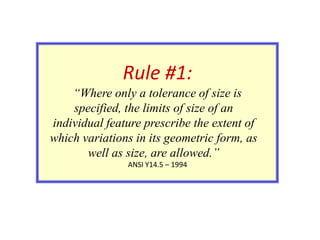

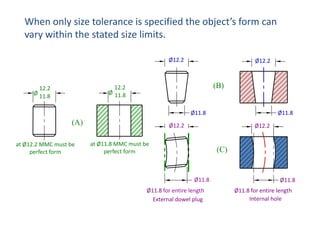

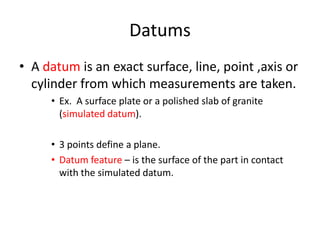

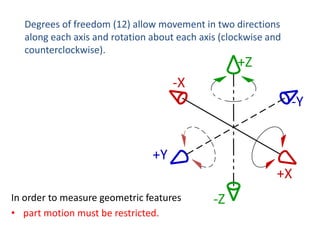

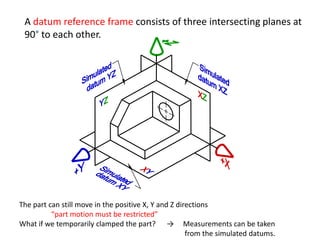

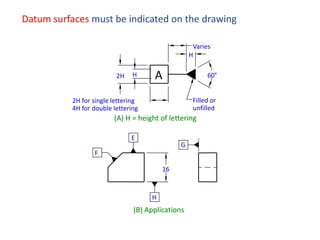

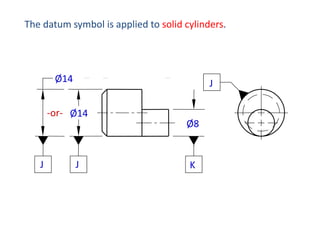

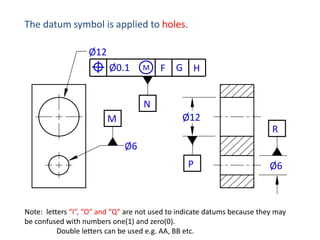

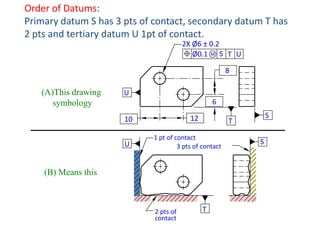

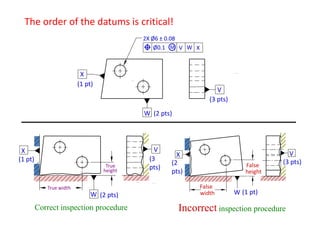

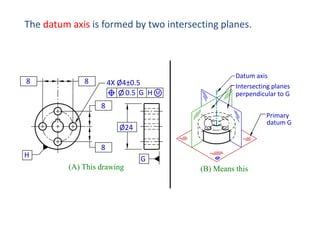

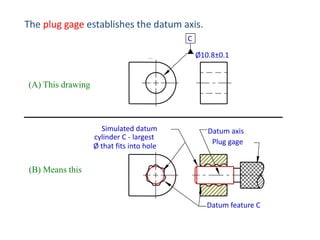

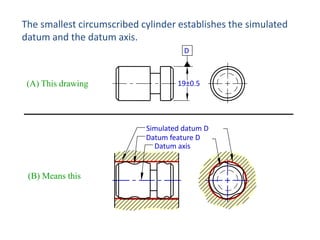

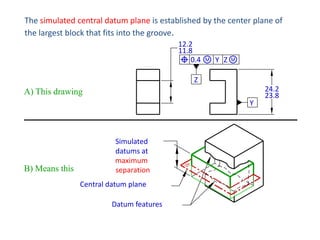

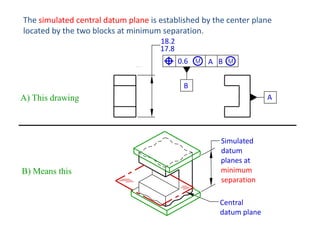

This document provides information about geometric dimensioning and tolerancing (GD&T). It defines GD&T as a method for defining the geometry of a part beyond simple tolerance dimensions. Feature control frames modify a part's geometry and include the geometric tolerance symbol, datum, and modifiers. Geometric characteristic symbols indicate the type of tolerance such as flatness, circularity, or perpendicularity. Datums establish the reference frame for measurements and include primary, secondary, and tertiary datums indicated on drawings.